Reverse Engineering in Industry

Reverse Engineering in Industry

Reverse engineering is used to generate CAD data. Special software is used here, which works in two demonstration experiments with CMM and a touch probe. There are many advantages to using this technique. In addition to immediate feedback and data reduction, the direct generation of the geometry and a higher precision of the end product are also among the positive benefits. RE is hardly limited in the number of its areas of application. This also has advantages for commercial areas. In this article we would like to take a closer look at various areas of application of reverse engineering for industry.

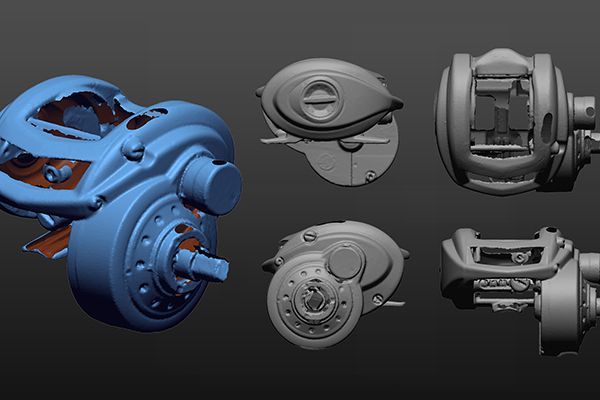

The Areas of Application – Why Reverse Engineering?

Manufacturing and technology rely on RE for a variety of reasons. It is generally used to find out how devices or products are made. The function of a product can also be more easily understood through remodeling. By dismantling technical devices or products into their individual parts and checking them for their materials and function, we can help companies in various ways. On the one hand, we enable the determination of the production processes and their process optimization. On the other hand, this also enables patents to be protected. Various possibilities. You too can benefit from our range of services.

The process can also be used to determine how old (and: very old) components of different products work. This may be necessary if the original technical drawings no longer exist or the former manufacturer no longer exists. Multidisciplinary expertise is essential for RE. Likewise, experience in deconstructing a product is vital. Rely on our expertise. Trust in our experience.

Examples of RE in Industrial use

Below are some examples that were presented to us by industry experts. Find out more about the Reverse Engineering Service (RES) here:

- CAD data for mold making

Often times, clay modeling is still used to create shapes and models during the design process. RE helps here in two ways:

- 3D scan of the clay model,

- RE and free-form modeling of the 3D scan STL file (Catia V5 / v6)

Would you like an example? We’ll give you one. Think of candy here. And now think of a Santa Claus milling shapes out of chocolate.

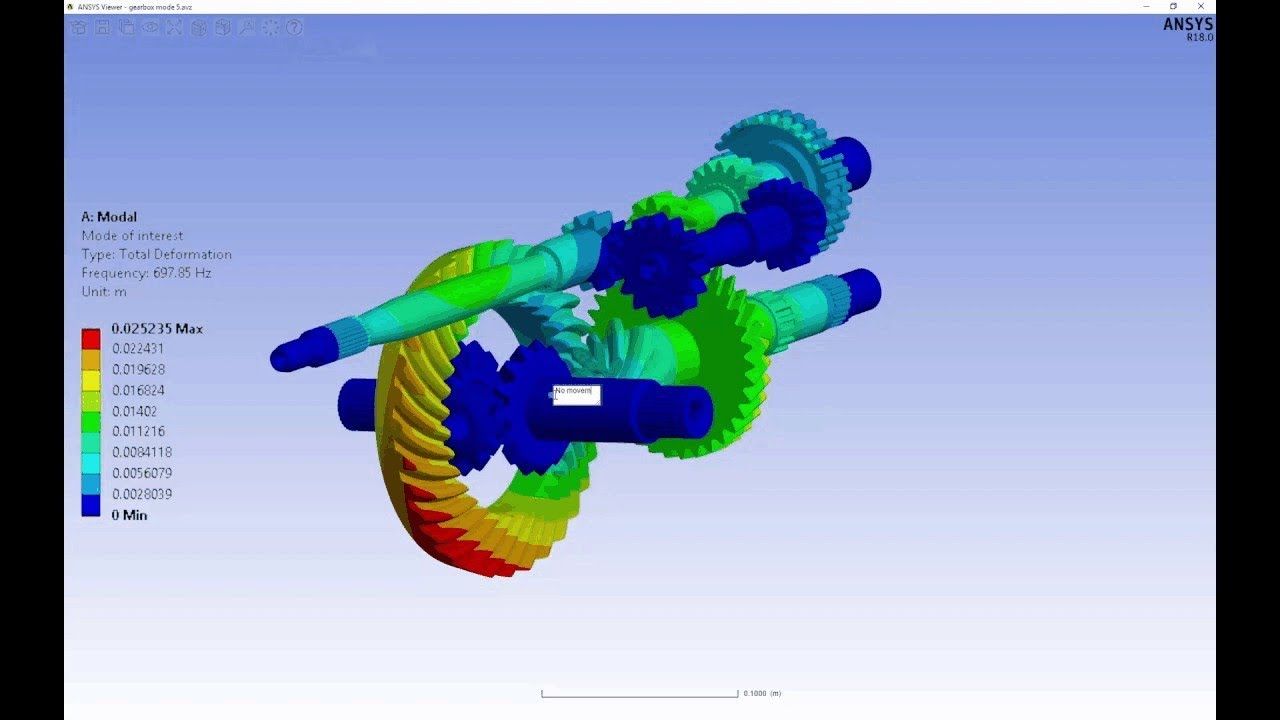

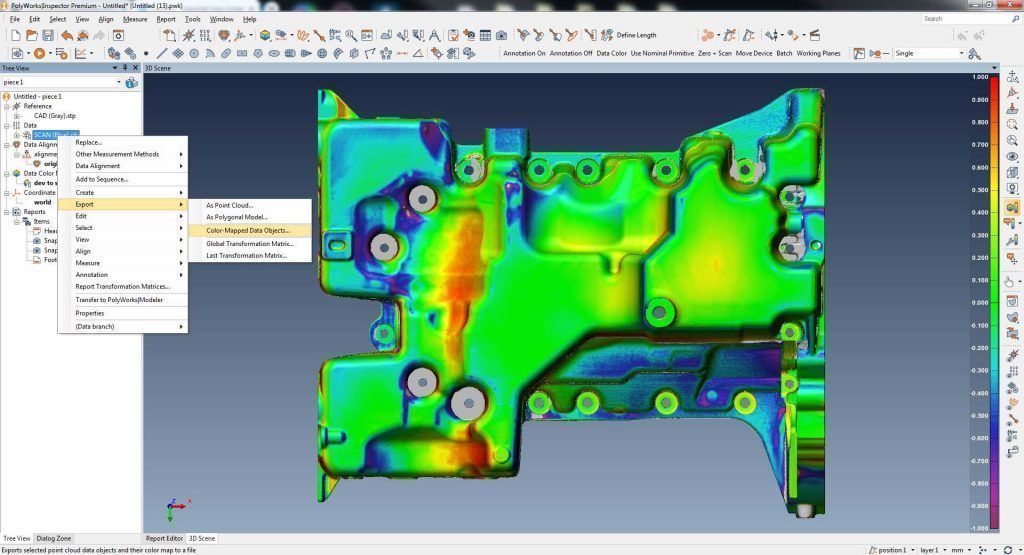

Another area of application is CAD data for the construction of injection molds. Here Cadmold software simulates the material flow during the injection molding process. The simulation is based on the original CAD design file. The result of this simulation is a point cloud with variations on the surface. And this point cloud in turn represents the expected result of the molding process.

RES converts this point cloud back into CAD data. Based on this new CAD file, the shape design can be further optimized. In this way, tolerances can be shifted to sections outside the desired framework. Here RES works in the following way:

- Moldflow simulation of hot plastics with Cadmold software,

- RE with free-form modeling and remodeling of parametric geometries (various software)

Here, too, we have another example for you. This time, think of a much more important area. Think about hospitals. A classic application in this sector is the injection molding of plastic parts for use in ventilators.

Mako-Technics is your contact for all reverse engineering issues. Please visit us on our website. Contact us if you have any further questions. We are looking forward to your message.

There are no comments