Reverse Engineering for Product Analysis

Reverse Engineering for Product Analysis

Reverse engineering is generally understood to mean a method with which existing products can be examined in detail and then reconstructed. Our service is used in a wide variety of application areas. For example, by precisely disassembling a component, we get accurate data that says a lot about how it was manufactured and the original design intent. Our service not only offers advantages for the often necessary procurement of spare parts – reverse engineering is also ideal for product analysis. It doesn’t matter whether it’s about your own quality management or examining competitor products. Would you like to learn more about this? Then you are exactly right here.

Need quick help from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

Product Analysis by Reverse Engineering – How does it work?

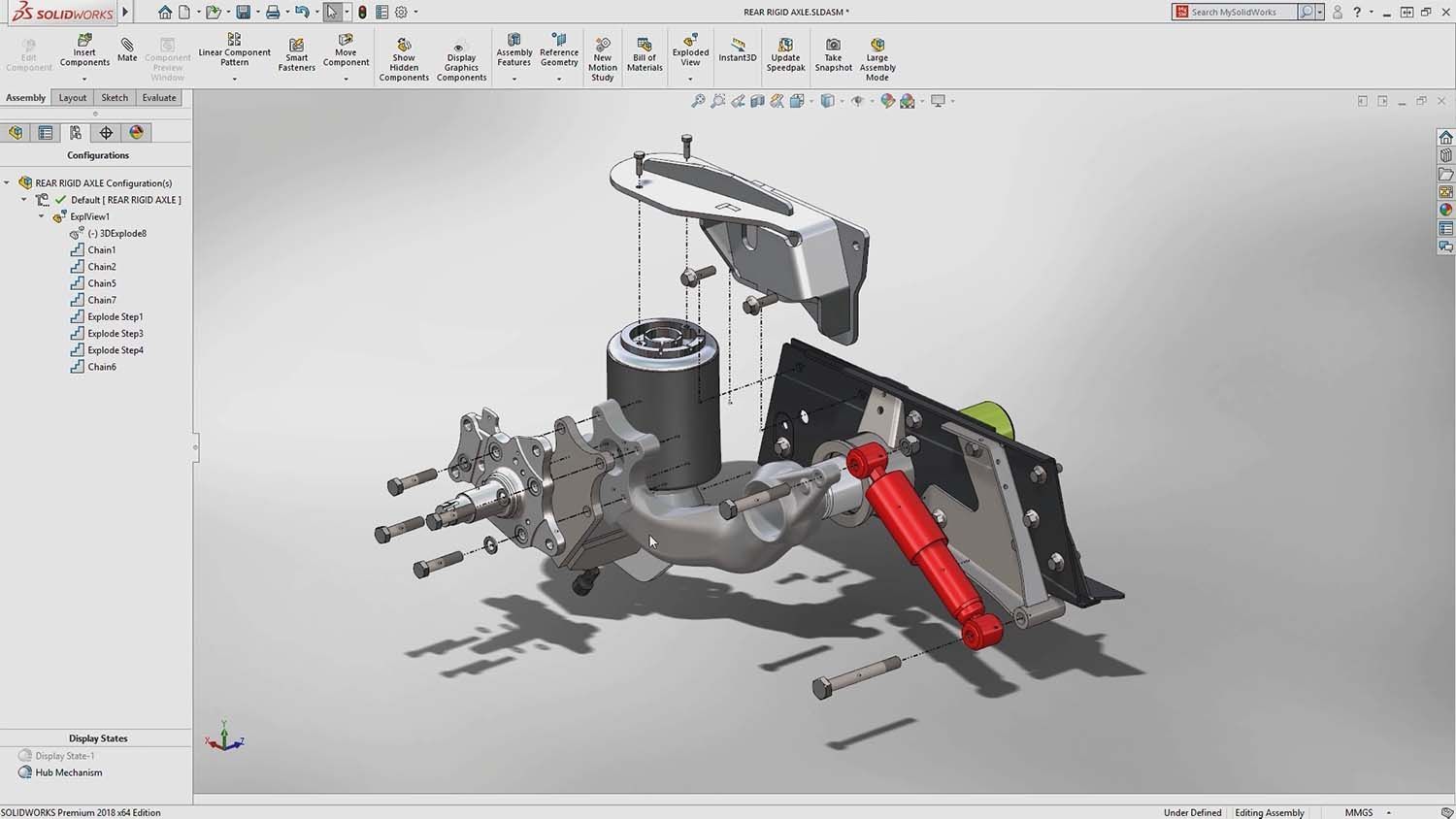

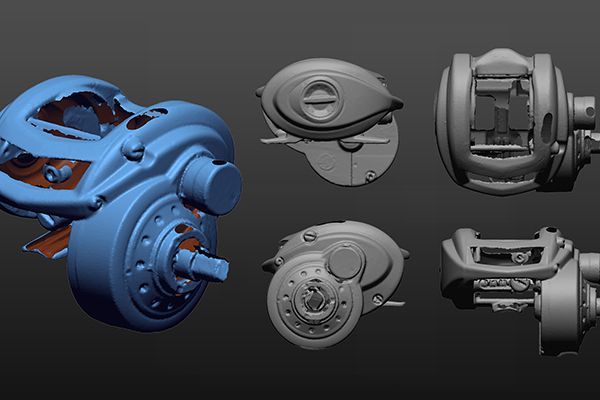

Reverse engineering describes a technical approach with which objects such as components are precisely examined and digitized in order to then be able to reproduce or improve them. In order to obtain the most accurate data possible when examining an object, we use precise 3D scanners in the first step. This gives us an exact point cloud of the respective object, with which we can examine it in more detail. At the end of our process, we provide our customers with the required 3D CAD model, which can be used for a new production, for example.

But we don’t just help our customers to produce new parts that they need. In many cases it may be advisable to examine products in more detail. For example, to check them for vulnerabilities. It doesn’t matter whether it’s about your own or third-party products. Reverse engineering also helps with product analysis – a use case that is often underestimated.

Tip: Follow us on LinkedIn or Facebook and never miss a post again! We would be happy to welcome you as a follower.

Examine products and components in detail

Using the point cloud provided by the 3D scan and the CAD model provided by our service, it is possible to examine in more depth how it works, manufacturing principles, behavior and other properties. If we are talking about a competitor’s product, this can be inspected for advantages over our own products, for example. But another reason for reverse engineering in product analysis is of much greater importance: its use in your own quality management.

By the way: Here you can find out more about the various areas of application.

In quality assurance, companies can use our service to examine both prototypes and finished end products in detail. If these inspections are carried out at regular intervals, any production defects can be identified at an early stage. Would you like to increase the quality of your products? Then rely on reverse engineering from Mako GmbH for your product analysis.

Do you have further questions about our service? Contact us anytime! We look forward to your inquiry and will be happy to advise you.

Would you like to learn more about exciting reverse engineering topics? Please visit us on YouTube! There we regularly provide videos on exciting topics.

There are no comments