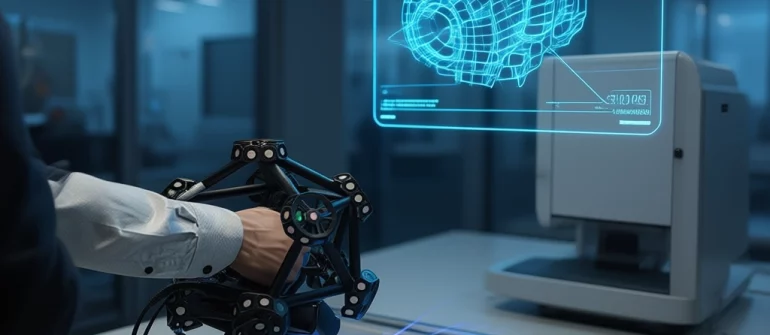

Top Reverse Engineering Tools for Solidworks Users For Solidworks users looking to enhance their design capabilities, leveraging reverse engineering tools can significantly elevate your 3D…

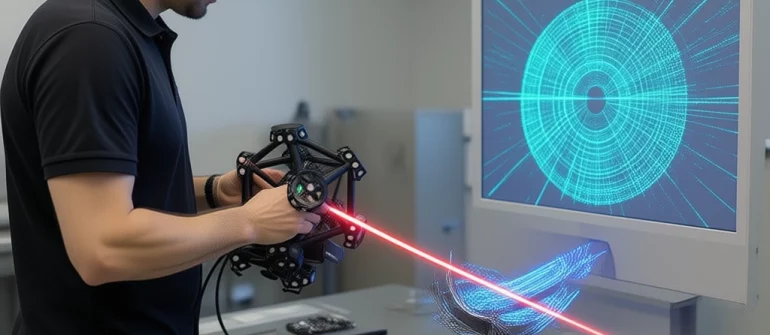

Unlocking Reverse Engineering with 3D Scanning Technology 3D scanning technology is revolutionizing the field of reverse engineering, offering unparalleled accuracy and efficiency. By converting physical…

Top Techniques for 3D Reverse Engineering Success 3D reverse engineering is revolutionizing how industries approach design, prototyping, and product development. By utilizing advanced 3D scanning…

Top Benefits of 3D Inspection Scanners for Quality Control Quality control is an essential aspect of manufacturing and product development, ensuring that every item meets…

Top 5 Benefits of 3D Scanning in Healthcare The healthcare industry is rapidly evolving, and one of the most groundbreaking advancements is the integration of…

Discover How 3D Printing Transforms Design Education Imagine a world where your creative ideas can materialize before your eyes, where concepts leap off the page…

Unlock Precision: Laser Scanning Solutions for Reverse Engineering Laser scanning is revolutionizing the field of reverse engineering, offering unparalleled precision and efficiency. As industries increasingly…

Top 5 Benefits of 3D Capture in Metrology Automation 3D capture technology has revolutionized the field of metrology automation, providing solutions that enhance measurement accuracy,…

Unlocking Automotive Reverse Engineering with 3D Scanning 3D scanning is revolutionizing the field of automotive reverse engineering, providing engineers and designers with unparalleled precision and…

Boost Efficiency in 3D Scanning Preparation Today When embarking on a reverse engineering project, the preparation phase for 3D scanning can often feel daunting. However,…