How Reverse Engineering helps Industry

How Reverse Engineering helps Industry

In today’s world of work, it is often necessary for objects such as components or tools to be available in digital form. A CAD model is often required for this in the industrial sector. But what do companies do if such a CAD model is not available? This is exactly where the service from Mako GmbH comes in. In this case, our team digitizes the corresponding component or object and then provides a precise CAD model. In what other areas does reverse engineering help industry? Mako-Technics provides information about this in this article.

Need quick help from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

Reverse Engineering: Assistance for the Industry

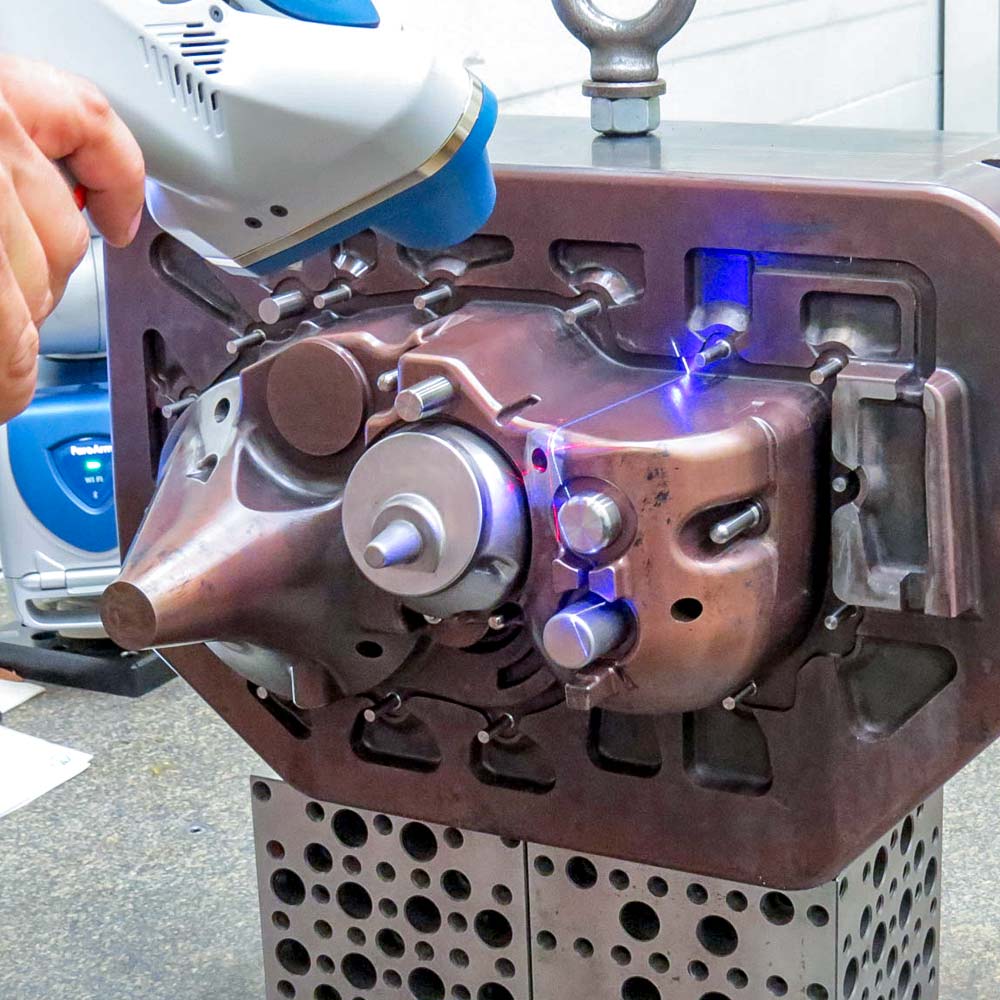

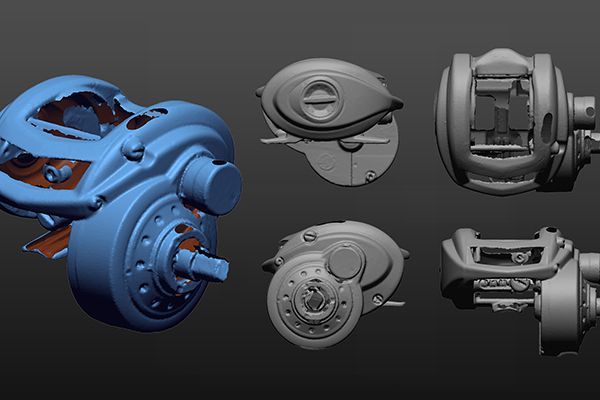

Do you have tools for which you no longer have any design information? Do you have an order for 3D printing, but do not have a CAD model, only the original part? Then Mako-Technics is your contact! Because this is exactly where our service comes in. In these cases, your required object will first be scanned by us. High-precision 3D scanners are used here, which provide us with an exact point cloud, i.e. a digital intention of the component.

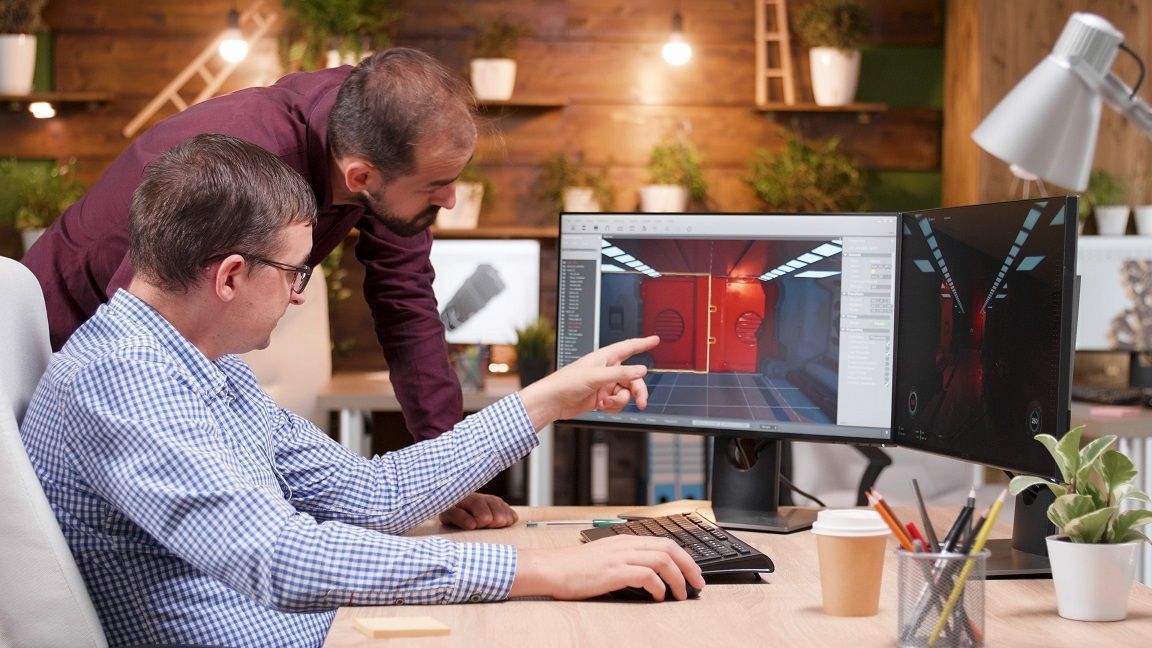

We then use the data obtained to create the required 3D CAD model. In this way, the reverse engineering service helps industrial companies to produce the required components, renew them or even optimize existing parts.

Industrial applications

The areas of application of reverse engineering are also extremely diverse in the industrial sector. In fact, they are almost unlimited in number. Would you like to learn more about these areas? Our service offers effective solutions in the following areas:

- Mechanical engineering

- Toolmaking

- Tool correction

- Quality management

- Rapid prototyping

- Additive manufacturing

- And many more.

The Benefits of Reverse Engineering for Industry

The advantages of our service are obvious. In many cases, the use of reverse engineering enables faster and more efficient production. However, the supply of spare parts and the maintenance of machines is often more economical thanks to our service. In this way, costs for manufacturing processes and development can be reduced to a more tolerable level. Reverse engineering also saves companies a great deal of time in many areas.

You have further questions? Feel free to contact us at any time! We look forward to your inquiry and will be happy to answer it.

If you would like to learn more about us, reverse engineering or other industry topics, please visit our blog! With regular new topics and articles, this offers you an effective opportunity to obtain comprehensive information.

There are no comments