Reverse Engineering Offers Security

Reverse Engineering Offers Security

Reverse engineering is a process in which objects are examined in such detail that they can then be easily reproduced. There are hardly any limits to the multitude of application areas. RE helps, among other things, in mechanical engineering, mold making and other countless industries. However, it does not only exploit its potential when designing new parts. Many companies do not produce themselves or only do so in part. You are therefore dependent on certain sub-suppliers. In these cases, reverse engineering offers one thing above all: security. How exactly is that possible? The experts at the Reverse Engineering Service explain this in this article.

Do you need help quickly from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

Security through Reverse Engineering: It’s not just about reproduction

One factor in particular is decisive for the quality of industrially manufactured products: the issue of safety. Manufactured parts or products must at no time pose a risk to consumers or those involved in the manufacturing process. It doesn’t matter whether we’re talking about an already finished product or whether it is still being processed.

Manufacturing companies can of course only guarantee safety for the parts they produce themselves. Components, tools or parts provided by subcontractors can therefore pose a certain (residual) risk under certain circumstances. In such cases, there is usually a relationship of trust with your suppliers. Also in terms of the quality and safety of the products. But can you always be absolutely sure about this?

Security through Control

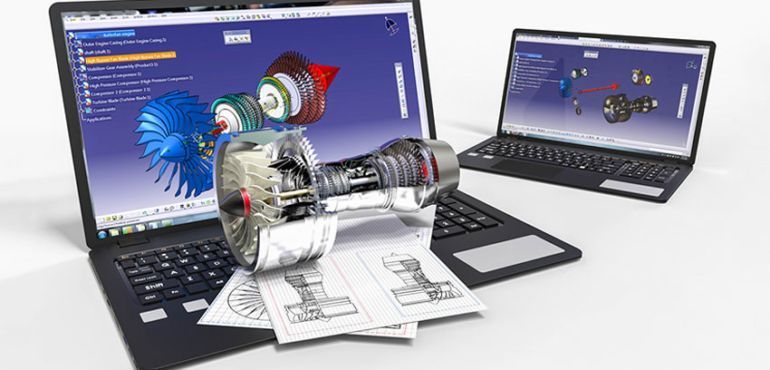

In these cases, reverse engineering can help. In order to be able to precisely check the original design intent and, above all, the quality of the production, the respective component is precisely measured and then converted into a 3D CAD model. Engineers can then use this CAD model to check how this part will behave under certain conditions. This gives companies security. The certainty that the products or parts supplied by upstream suppliers will also meet your requirements. In this way, safety can be guaranteed for your own employees, but also for customers.

Precise Reverse Engineering through precise measurement methods

In order to measure these parts precisely, it is necessary to use precise measuring devices. You can choose from, for example, 3D scanners or coordinate measuring machines. If high precision is required and the respective component is not too small, we use 3D scanners for this. This gives us a point cloud, which our team then converts into CAD-compatible volume data.

The Mako-Technics team

Would you also like to use reverse engineering for your company? Use the service of Mako-Technics! We offer you quality made in Germany. You too can benefit from our experience. Make us your partner and benefit from our know-how. Contact us!

If you would like to find out more about us or other topics related to the industry, just have a look at our blog. There we offer you a lot of information with regular articles.

There are no comments