Reverse Engineering in 3D Printing

Reverse Engineering in 3D Printing

In this Blog article, Reverse Engineering Service experts Mako GmbH explains how to improve your production using Reverse engineering and 3D printing.

Reverse engineering can help you to totally rethink your manufacturing process and help you improve it. However, developing new solutions is not always easy and can be time-consuming. This is exactly where 3D technologies come to the rescue. What exactly is reverse engineering and how can combining it with Additive Manufacturing revolutionize your production methods?

What is Reverse Engineering (RE)?

Reverse engineering, otherwise known as back engineering, is a method of learning by taking apart objects in order to learn how it was produced without any previous knowledge of it.

The purpose of RE is not only to copy the part but to learn how it was produced and gain knowledge of the manufacturing process. That allows improving the part or finding new solutions along with reproducing the part accurately.

3D Printing and Reverse Engineering: Two Complementary Methods

There are many advantages when it comes to using 3D technologies for back engineering purposes. They can highly improve product development and prototyping stage, which affects the final product. 3D scanning and 3D printing are the main methods beneficial for reverse engineering.

Turning your part into a 3D model

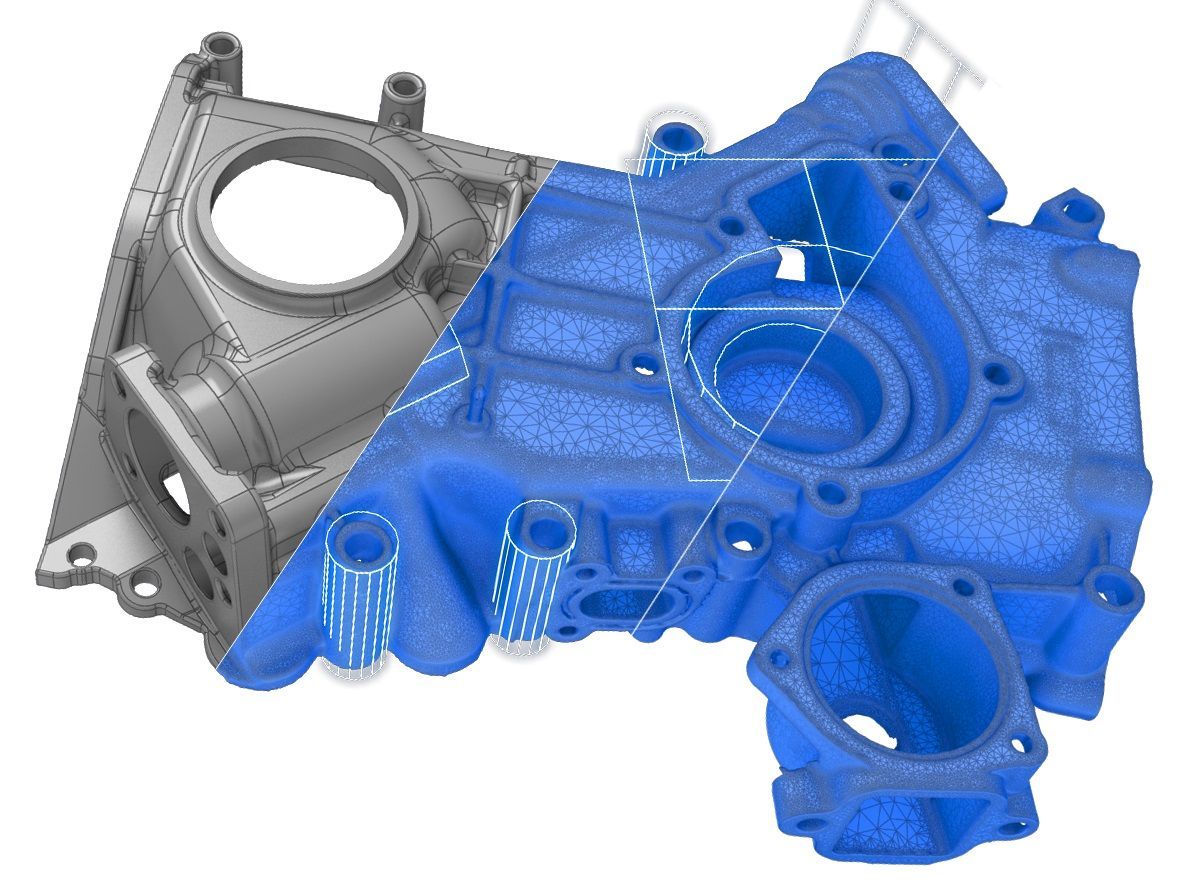

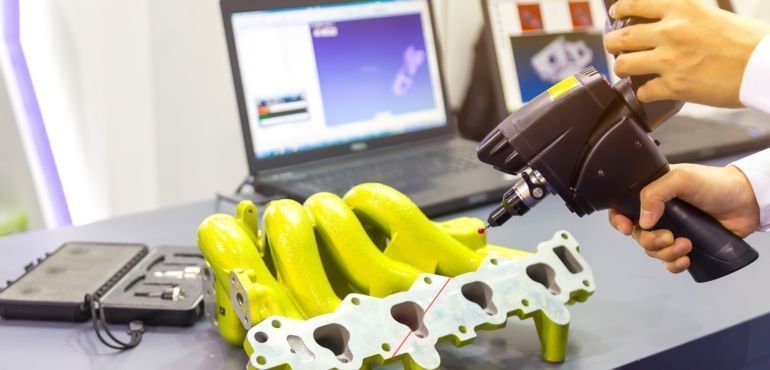

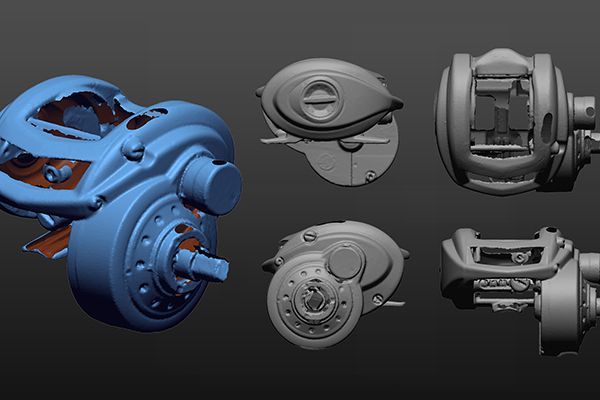

In order to examine an object for reverse engineering applications, 3D scanning comes in very handy. It allows to get an exact image of it in virtual reality. 3D scanners will produce a mesh, digital representation of the part in question build of triangles. Most CAD software doesn’t work with mesh objects as it’s not precise.

Once you have a precise 3D model, you can add to it any adjustments needed. CAD and 3D modeling software will allow you to run different stress tests and predict the behavior of different parts, exposing their weak and strong points. This is a huge advantage over traditional methods. Thanks to 3D scanning and CAD software (like SolidWorks) you will be able to shorten the development stage from weeks to just days.

Reverse Engineering and 3D Printing for the fastest prototyping process

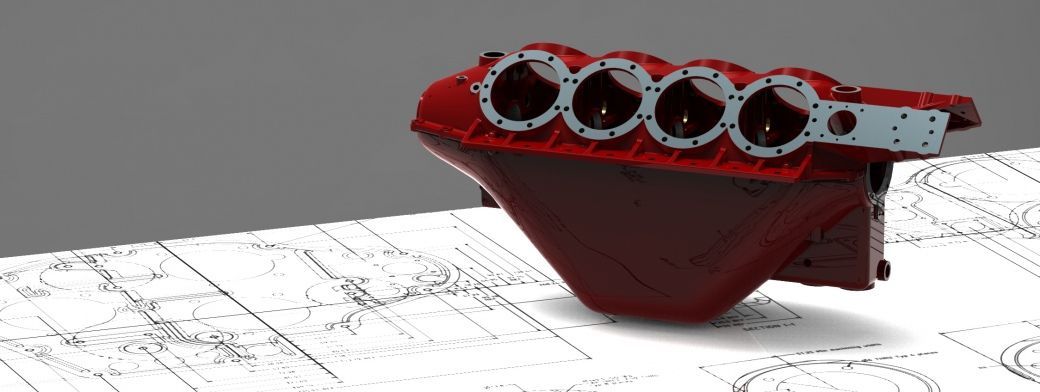

Additive Manufacturing will give you the possibility to make quick adjustments to the model and produce it in no time. 3D printing is a reliable and fast production method where you can also choose between different materials and technologies.

Thanks to RE you will deeply examine the object discovering the development methods behind it. You will gain knowledge which will help you to understand how the object can be modified and improved. You already know that 3D scanning and 3D modeling will allow you to create a digital version of the object, edit it and test it.

The next step is to actually produce the prototypes and 3D printing is a perfect solution for that. You can choose between different plastics, resins and even metal materials. Thanks to the wide range of technologies, Additive Manufacturing will also produce your prototypes quickly. This means fast, more efficient and less expensive production.

3D Printing not only for prototyping

Although Additive Manufacturing technologies are well known to be reliable for rapid prototyping, they actually came a long way since. Thanks to RE and many options available for 3D printing, you can produce fully functional parts. Your manufacturing process will be more efficient and faster, additionally can be improved by bringing many costs down.

If you want to explore more about Reverse Engineering, other CAD software and how to master them check out our Blog Posts here or contact us here to get in touch with a Reverse Engineering expert!

There are no comments