Reverse Engineering for Modernization of Legacy Product

Reverse Engineering for Modernization of Legacy Product

In this Blog article, Reverse Engineering Service expert Mako GmbH discusses how we can use RE to modernize legacy products.

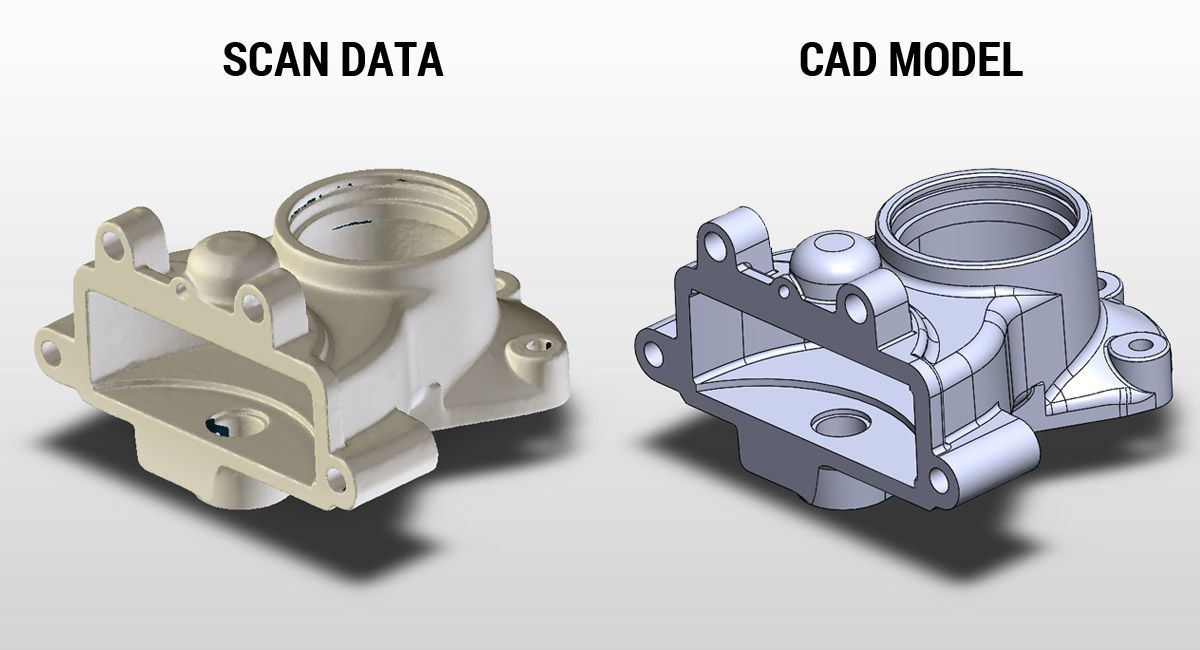

By reverse engineering surfaces and physical parts that have little or no design documentation, Mako GmbH can modernize legacy products. If a component’s initial design intent has been partially lost as a result of production process variation or tool degradation or Diminishing Manufacturing Sources and Material Shortages (DMSMS), this process can help identify and correct problems.

The Process:

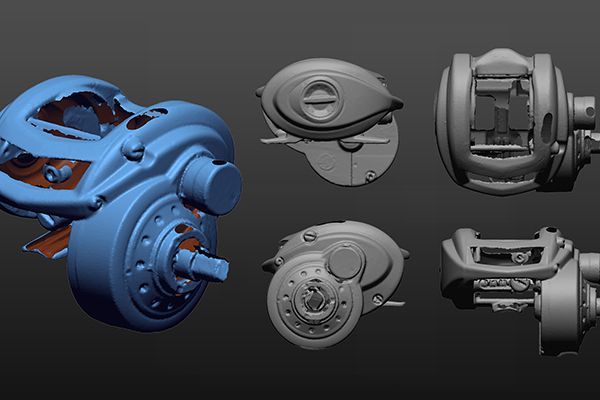

Once we collect detailed 3-dimensional data from your legacy product, CAD models can be easily created to facilitate changes, corrections and upgrades to product or tooling design. This accelerates the iterative process by which today’s products and processes are modernized and improved.

When legacy product or tooling is poorly documented by dimensional drawings, conventional measurement tools aren’t adequate when complex 3D shapes are involved. Our non-contact inspection process solves this problem without damaging or altering your product or tools in the process.

If you want to explore more about RE, 3D Scanning, CAD software and how to master them check out our Blog Posts here or contact us here to get in touch with a Reverse Engineering expert!

There are no comments