Why do Businesses need Reverse Engineering?

Why do Businesses need Reverse Engineering?

In this Blog article, Reverse Engineering Service expert Mako GmbH explains the primary uses of Reverse Engineering in businesses. Now a days most companies turn to reverse engineering for problem solving from increasing productivity to cutting costs in business.

How you can use Reverse Engineering for your Business?

Reverse Engineering (RE) has come a long way with the advancements in technology and has almost become a necessity for most businesses. RE can be used for forensics and problem-solving, part improvement, replacing legacy parts, corporate espionage & competitor intelligence, improving product documentation, educational purposes, and much more. One of the most recent examples of the power of reverse engineering is Porsche and Audi’s Tesla Model 3s.

Porsche and Audi are working together to develop the next-generation EV platform. They ran into some issues when they discovered that Tesla’s PPE (Premium Platform Electric) was better than they thought. The Model 3’s platform is not only superior in technology — it’s cheaper to produce.

RE gave them the tools necessary to size up their competition. Porsche and Audi are now looking for ways to reproduce Tesla’s technology for their own vehicles while keeping costs low enough to make it worth it.

Let’s explore some more ways that reverse engineering can be used for 6 different types of projects:

- Forensics and Problem-Solving

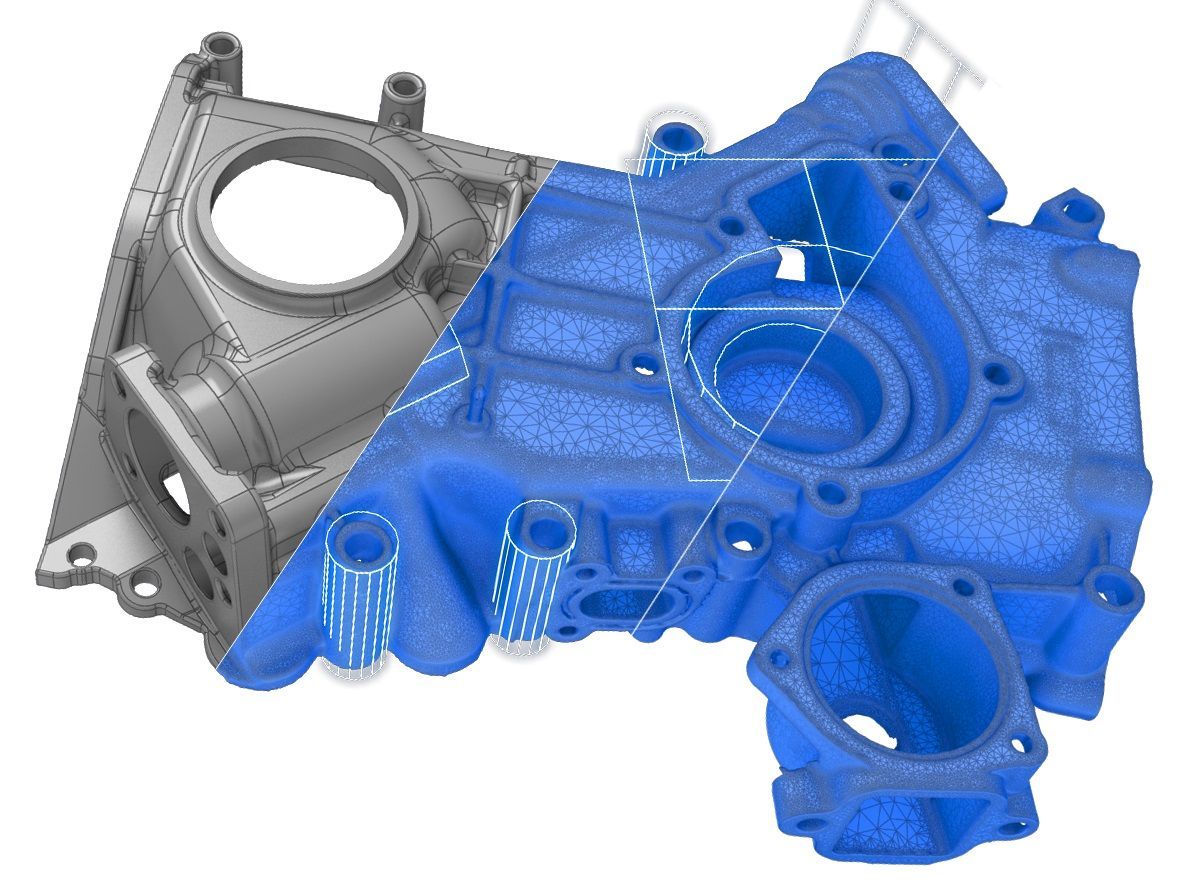

Reverse engineering can be used to discover product defects or help you understand why your machinery or equipment is malfunctioning. In the past, engineers would have to take a product apart and attempt to put it back together manually in order to learn how it works and discover flaws.

With advancements in technology, engineers can now trace over existing parts and assemblies and input them into a CAD system. This gives them a big picture view so they can pinpoint problem areas and come up with solutions to fix it.

- Part Improvement

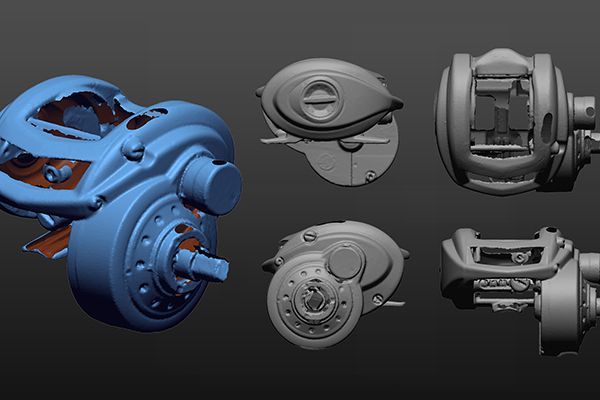

The same techniques that are used for forensics and problem-solving can be used to improve parts. You can take parts that are no longer useful and reverse engineer them to find any imperfections. The parts can be redesigned to fix those flaws, or redesigned to serve another purpose.

- Replacing Legacy Parts

Machinery and equipment are expensive purchases. In order to receive the most ROI (return on investment) for those purchases, you need to keep them up and running for as long as possible. When parts break or malfunction, you need to be able to replace them.

Sometimes this isn’t possible because the manufacturer goes out of business, or they stopped producing the part you need. Reverse engineering gives you the power to replicate and reproduce those parts for yourself so you can keep your machinery running longer.

- Corporate Espionage & Competitor Intelligence

RE powers innovation, as seen in the case study above about Porsche and Audi’s Tesla project. You can discover how a competitor’s product works and then make improvements to create your own, better product. This helps you gain a competitive edge and inspires engineers to produce the best possible product to serve a specific purpose.

- Improving Product Documentation

Product documentation can be incomplete, missing, or difficult to understand. RE makes it possible to discover how a product was made and how it works so new documentation can be created.

- Education to Improve Future Production

Engineers can learn a wealth of information by reverse engineering software, products, parts, and more. The more objects they reverse engineer, the more skills and techniques they learn that can be used for creating something new. RE inspires engineers to keep redesigning and repurposing products until they can’t improve on them anymore.

How to determine if Reverse Engineering is right for your business?

Every situation is unique, and reverse engineering might not be the best possible solution. Our team of highly skilled engineers can analyze your situation and determine if reverse engineering is the right course of action for you to take. Once we have determined that RE suits your needs, we can help you get the job done in a timely manner.

We at Mako GmbH can reverse engineer anything as small as a golf ball or as big as an entire manufacturing facility and more. We use top-quality machines combined with best-in-class software to make sure that everything we produce meets our high standards. We can even put your prototypes to the test by running them through production in our fully equipped manufacturing and fabrication shop.

If you want to learn more about Reverse Engineering, CAD software and how to master them check out our Blog Posts here or contact us here to get in touch with a Reverse Engineering expert!

There are no comments