Unlock Efficient Design with 3D Printing Solutions

Unlock Efficient Design with 3D Printing Solutions

As industries evolve, the need for rapid prototyping and innovative design strategies has never been greater. Enter 3D printing—an indispensable tool that transforms ideas into tangible products with remarkable efficiency. By leveraging additive manufacturing, designers can streamline their workflow, minimize costs, and enhance creativity in ways previously thought impossible.

Understanding the Benefits of 3D Printing in Design

3D printing offers a multitude of advantages that cater to various aspects of design and development:

- Speed: Rapid prototyping allows for quicker iterations, enabling designers to test multiple versions in a fraction of the time.

- Cost-Effectiveness: Reduces material waste through precise additive processes, making it more economical than traditional manufacturing.

- Customization: Facilitates unique designs tailored to specific needs without significant additional costs.

- Complex Geometries: Enables the production of intricate shapes that are often impossible to achieve with conventional methods.

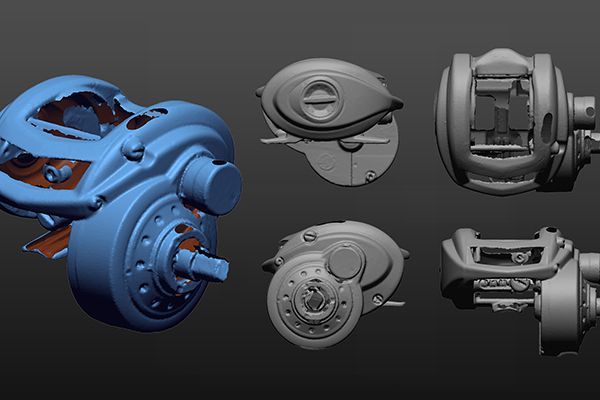

The Role of 3D Modeling in Efficient Design

3D modeling plays a crucial role in the 3D printing process. It serves as the blueprint for your project, allowing you to visualize and manipulate designs before physical fabrication. Here’s how effective modeling enhances your design process:

- Simplified Iteration: Easily modify designs based on testing feedback, enhancing overall product quality.

- Visualization: Offers a clear representation of the final product, aiding in stakeholder presentations and approvals.

- Error Reduction: Identifying potential issues in the modeling phase minimizes costly mistakes during production.

Diving Deeper: What is Additive Manufacturing?

Additive manufacturing, commonly known as 3D printing, involves creating objects layer by layer from digital files. This method contrasts sharply with subtractive manufacturing processes that cut away material from solid blocks. The key benefits include:

- Sustainability: Less material waste compared to traditional methods.

- On-Demand Production: Create items only when needed, reducing inventory costs.

- Diverse Material Use: Options range from plastics to metals and even bio-materials, broadening application possibilities.

The Power of Digital Fabrication

Digital fabrication, closely linked with 3D printing, encompasses various techniques for producing physical objects directly from digital designs. This synergy enables designers to quickly transition from concept to prototype development. Key elements include:

- Precision: Achieve high accuracy in dimensions and details.

- Aesthetic Freedom: Explore new forms and structures that enhance product appeal.

- Easier Collaboration: Share digital files effortlessly among team members for feedback and improvements.

The Importance of Prototype Development

The process of prototype development is vital in bringing ideas to life. With 3D printing, prototypes can be produced quickly and cost-effectively. Benefits include:

- User Testing: Gather real-world feedback early in the design process to refine your product.

- Tangible Evidence: Physical models help stakeholders understand concepts better than drawings or digital images alone.

- Easier Adjustments:</ strong>Create multiple prototypes with variations for thorough testing without breaking the bank.

The Future: Embracing Parametric Design

Parametric design, which relies on algorithms to define relationships between elements, empowers designers to create adaptable models that respond dynamically to changes. This approach integrates seamlessly with 3D printing technologies, allowing for enhanced flexibility in design modifications based on user inputs or environmental factors. Key advantages include:

- Avoiding Constraints:</ strong>No longer limited by traditional manufacturing capabilities; explore creative solutions without bounds.

- Savings on Revisions:</ strong>Easily tweak parameters instead of starting over—saving time and resources during revisions.

Selecting the Right 3D Print Materials

3D print materials is critical for achieving desired outcomes in both functionality and aesthetics. Considerations should include strength, flexibility, heat resistance, and appearance. Popular materials encompass:

- PLA (Polylactic Acid): Ideal for beginners due to its ease of use and eco-friendliness.

- ABS (Acrylonitrile Butadiene Styrene): Known for its durability and impact resistance; great for functional parts.

- Nylon: Offers superior strength and flexibility; perfect for complex applications requiring high performance.

Your Path Forward with 3D Printing Solutions

There are no comments