Related Posts

Geomagic Design X: Top Reverse Engineering Software Benefits When…

Unlock Efficient Design with 3D Printing Solutions As industries…

AR Future : Opportunities for the Working World Augmented Reality,…

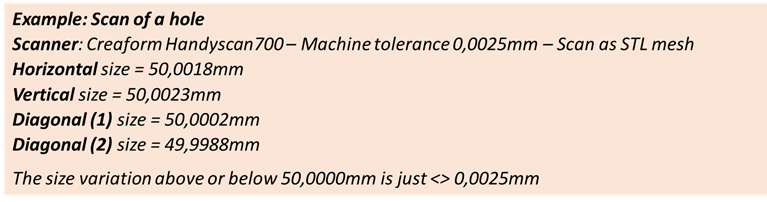

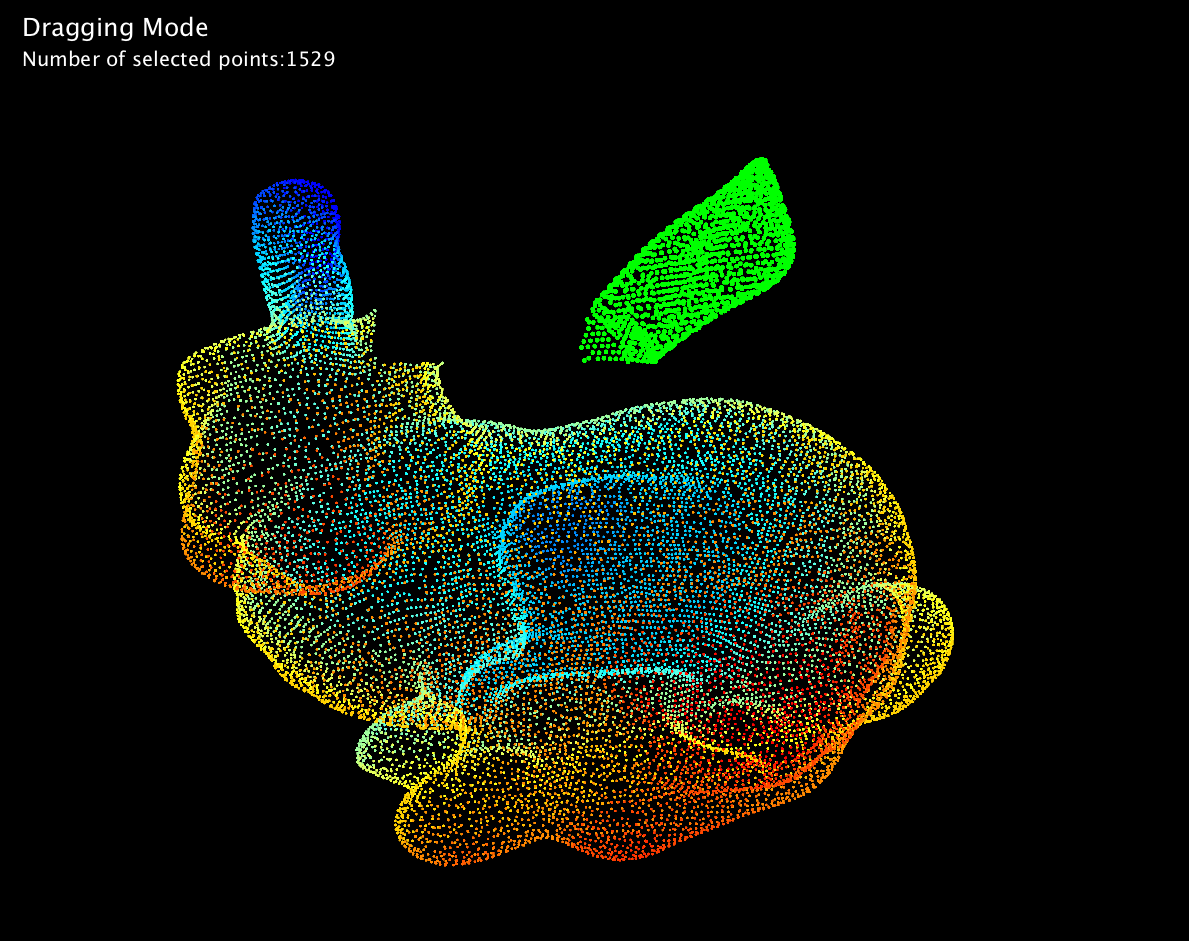

STL file – short explaination! STL is the most commonly…

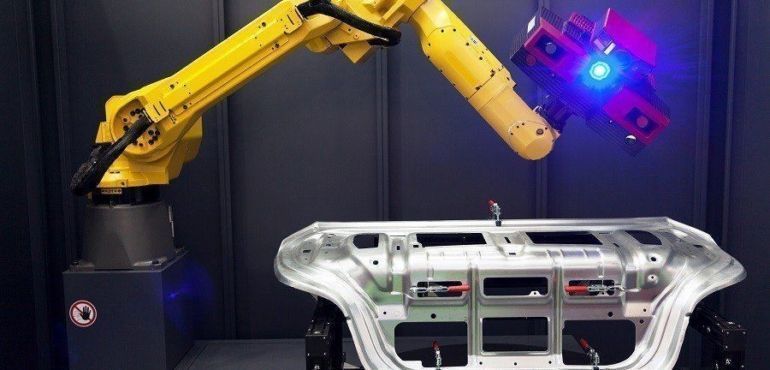

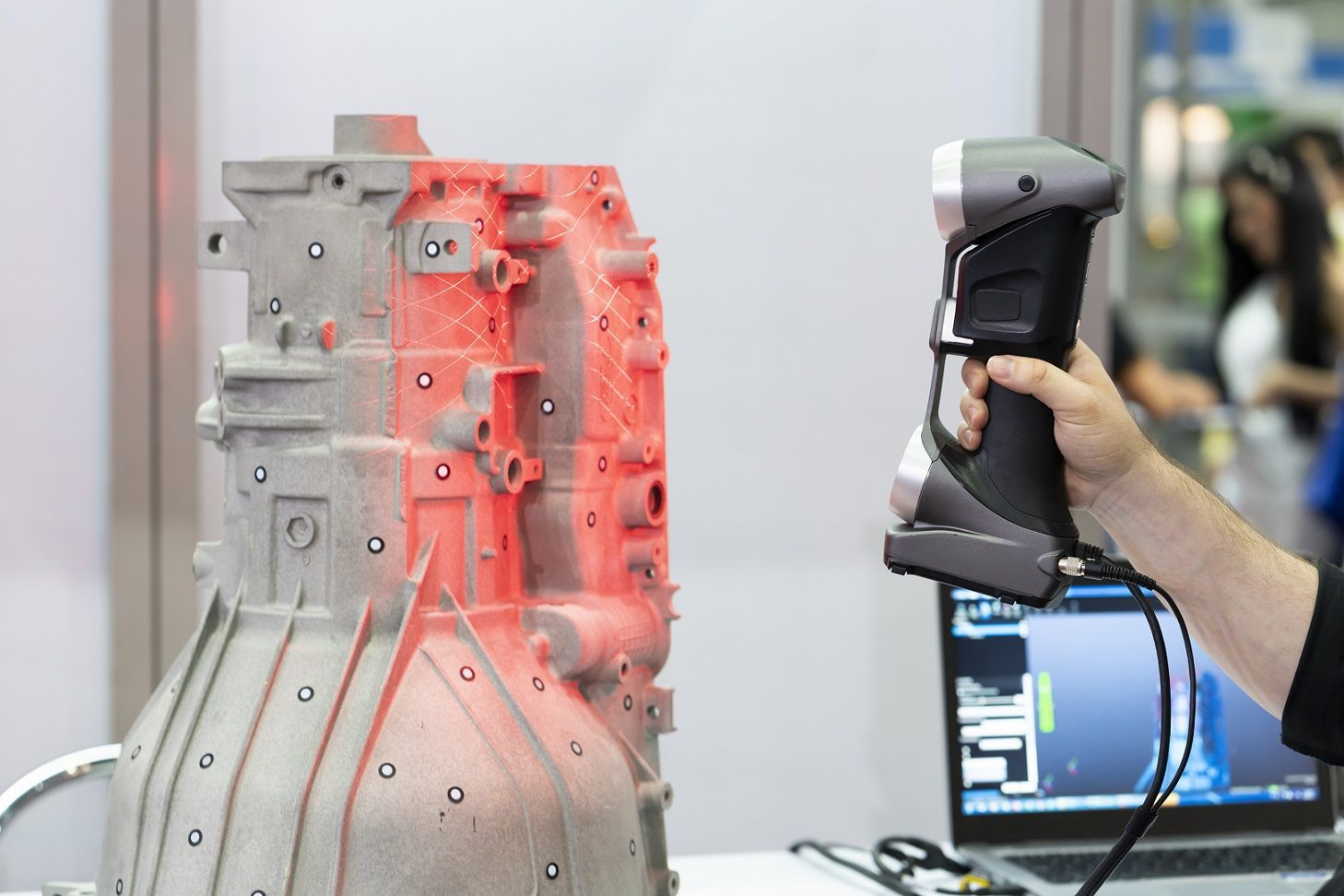

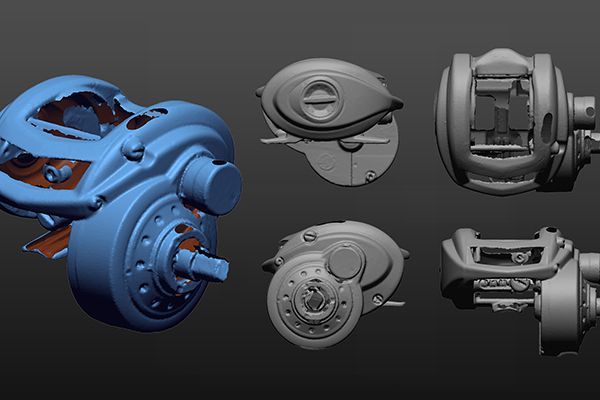

Reverse Engineering Potential Exact data for existing products or their…

Reverse Engineering, AR and Industry 4.0 Industry 4.0 is constantly…

There are no comments