Advantages of using CREO Parametric

What are the advantages of using CREO Parametric?

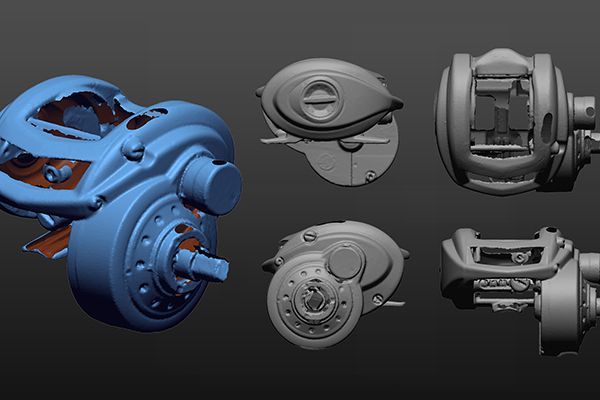

In this blog article, Reverse Engineering Service experts Mako Gmbh describes the advantages of using CREO for your CAD requirements. Creo is the industry’s one of the leading 3D CAD software. There are a ton of benefits of using Creo over the other software. The main advantages are discussed below:

OPTIMISED FOR MODEL-BASED ENTERPRISES

Creo has many added features to help more manufacturing businesses transition into model-based entities. There is a major focus on authoring features such as ASME and ISO standard support, and the calculation of enterprise consumption with the STEP AP 242 and JT Creo View Printing features.

INCREASED ENGINEER PRODUCTIVITY

Several features are now optimized to increase the productivity of users. Geometry based selection, a new mini toolbar and WSYIWIG customization will all help users design faster. In addition, with advanced rendering, waiting time has been reduced for images to be produced or have to work with poor quality renders.

BETTER DESIGN

The freestyle design now allows users to import and export control mesh and add finer detail to designs, as well as enabling more drawing flexibility. The advanced rendering also means that model images will be produced in a higher quality.

NEW ENGINEERING CAPABILITIES

The update has a whole new set of capabilities for engineers. Users can model sheetmetal directly, build accurate solid weld geometry in both parts and assemblies and reuse components through the intelligent mirror tool. New capabilities also allow for improved 3D design ability; engineers can now use a 3D sweep to draw along 3D trajectories.

INCREASED MANUFACTURING CAPABILITIES

With faster, more intuitive mold splitting and integrated material removal simulation, Creo allows manufacturers to gather advance information and make model changes more easily.

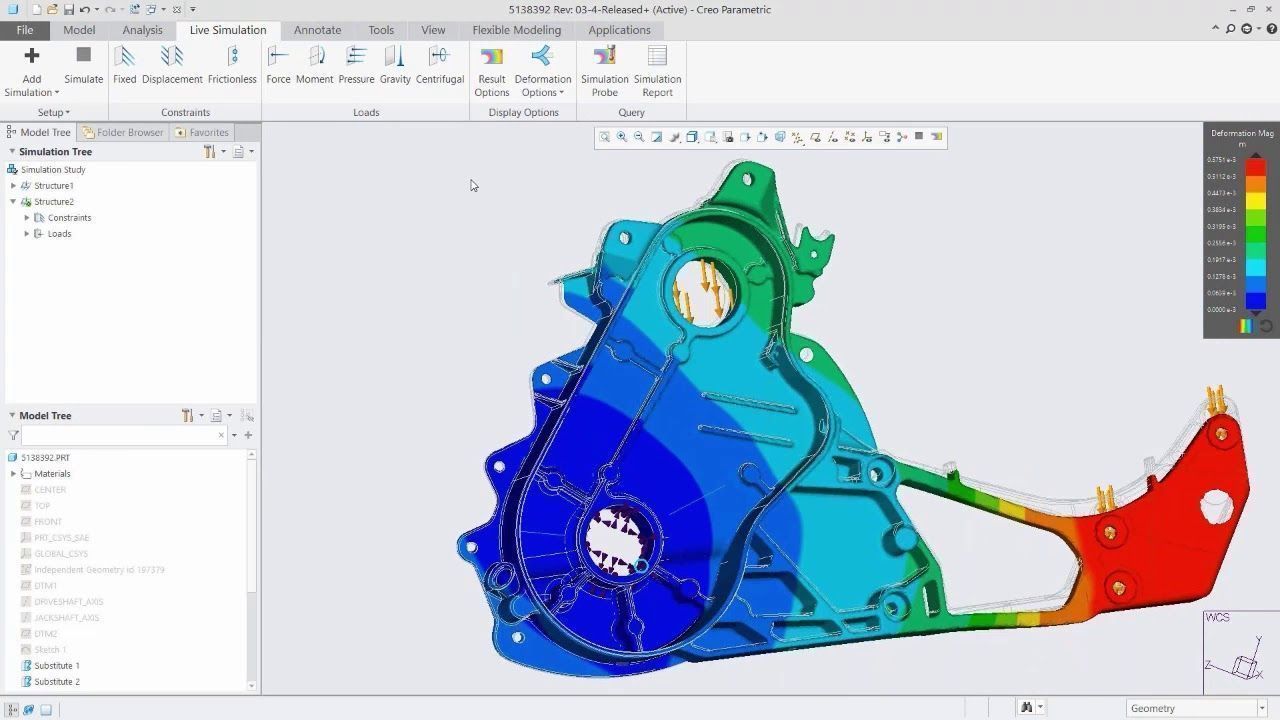

BETTER SIMULATION

The so-called ‘Digital Twin’ capability allows digital representations of unique occurrences of a physical product to take place. This allows users to gain greater insight into a product’s state, performance structure and behavior before sending it to manufacture.

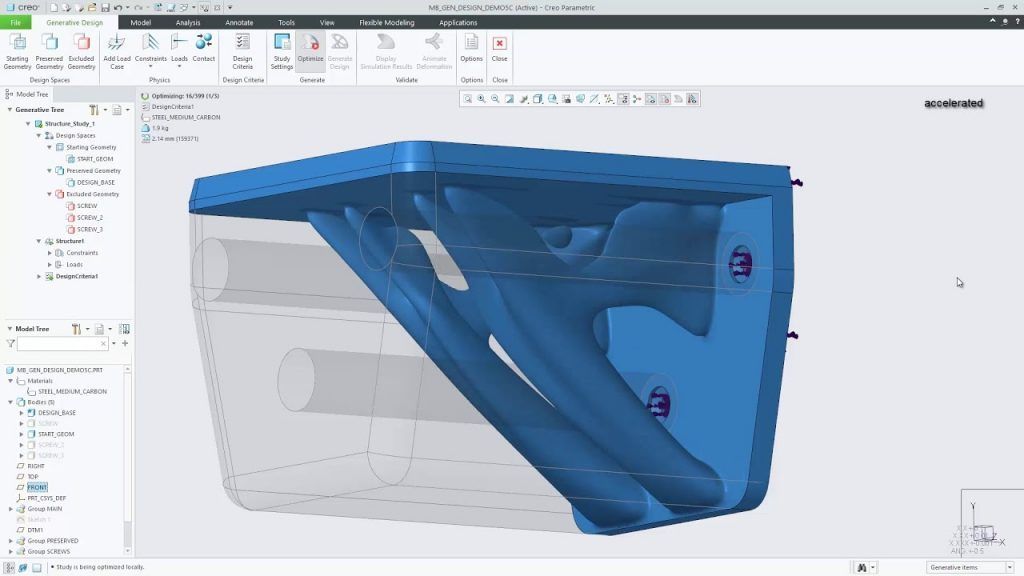

DESIGN CAPABILITIES FOR ADDITIVE MANUFACTURING

The ability to model both 2.5D and 3D structures as well as analyse and optimise them along with increased design capabilities for 3D printing, users have much more additive manufacturing capability. Tools also allow for lattice thicknesses to be varied for the improvement of strength in any specific region of a model.

CREO IS CREATED FOR MODERN ENGINEERING BUSINESSES

This upgrade is focused on increasing capabilities to suit modern engineering businesses, whether that be 3D design and printing, freestyle concept design or capabilities for model based enterprises. With more model knowledge, simulation and design capabilities, users can create models that are much better suited to the needs of modern engineering.

If you want to explore more about Reverse Engineering, other CAD software and how to master them check out our Blog Posts here or contact us here to get in touch with a Reverse Engineering expert!

There are no comments