Virtual Prototypes with Augmented Reality

Virtual Prototypes with Augmented Reality

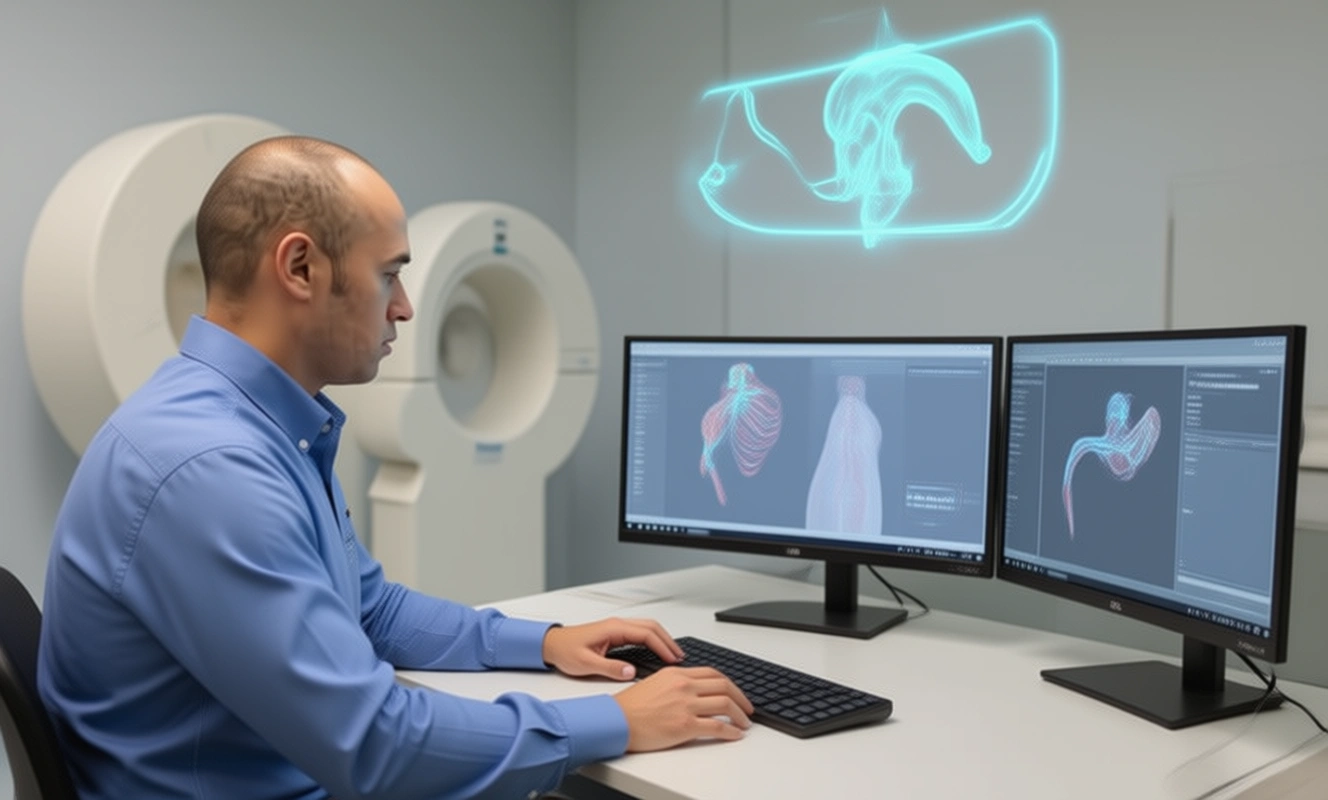

The Corona Pandemic turned product development upside down. Suddenly, face-to-face meetings were no longer possible. And even on prototypes, it was no longer possible to work with several people at the same time. One technology in particular has proven to be particularly helpful: augmented reality. The Mako-Technics team took a closer look at how AR has helped product development, especially with virtual prototypes.

Need quick help from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

Virtual prototypes within reach thanks to augmented reality

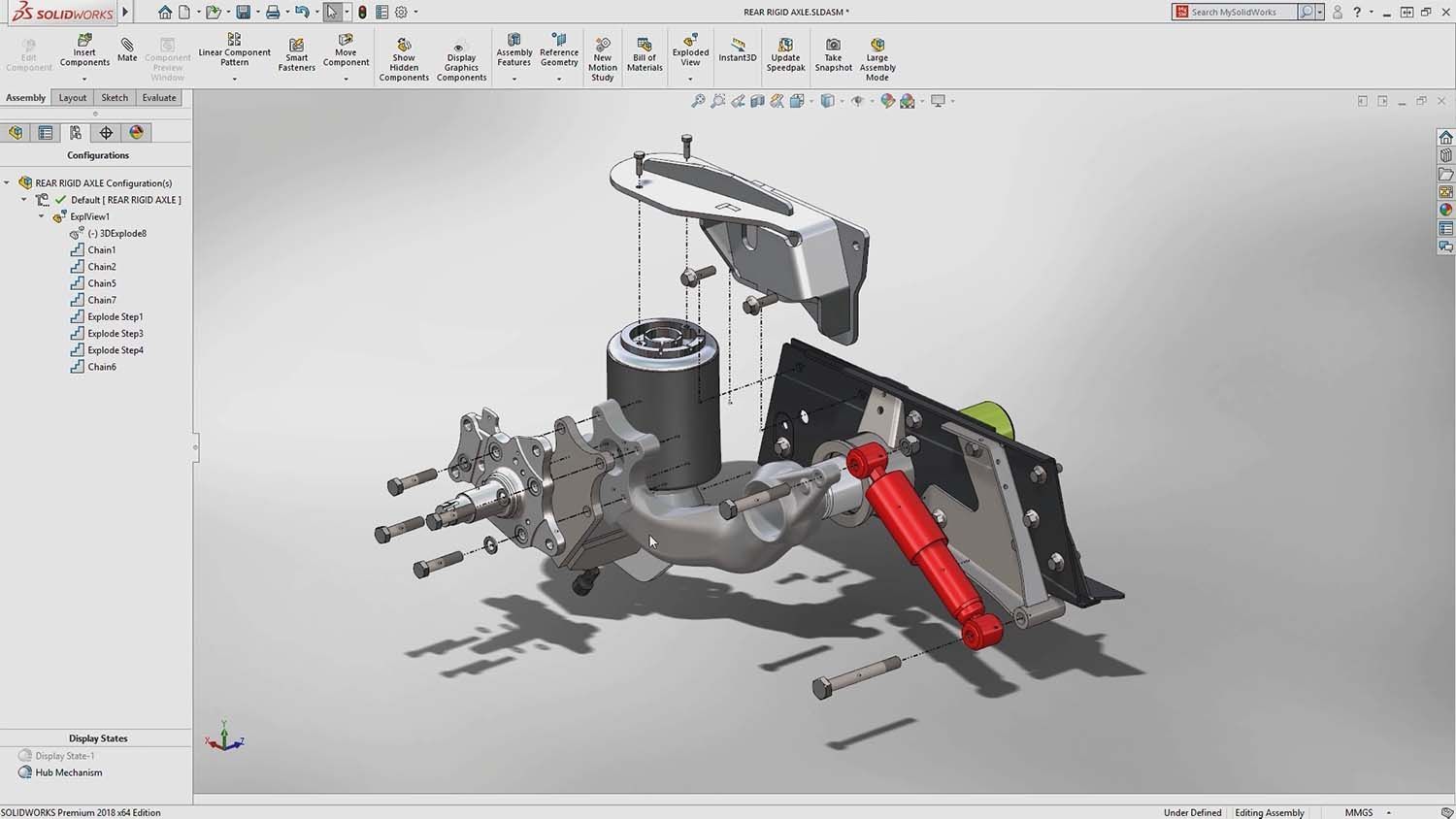

Prototypes are an indispensable building block for product development. On the way to a successful product, there is no way around them. On the one hand, they are used to check ergonomics and operation itself. On the other hand, any production defects are recognized early and eliminated by corrections. Prototypes are also very often used for presentation purposes, for example in front of executives or investors.

However, the current Corona Pandemic prevents employees from taking care of adjustments or corrections on a prototype at the same time. Without these work steps, however, there is a risk of a delayed market launch or even the release of an inferior product because it could not be tested sufficiently in advance.

This is exactly where Augmented Reality offers the solution.

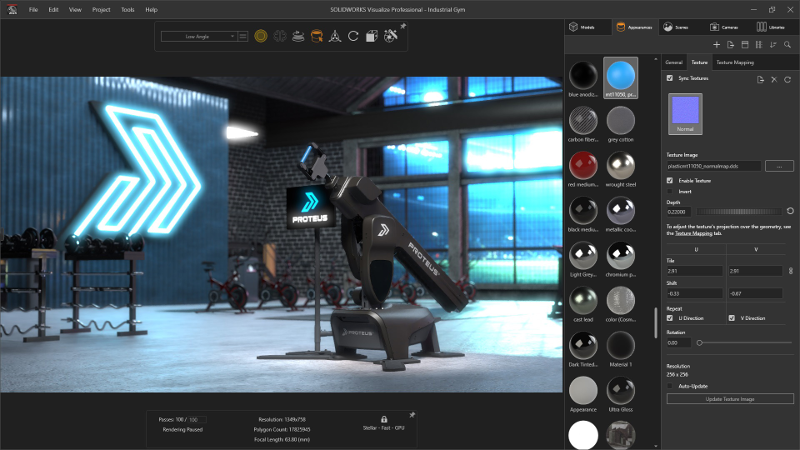

Virtual design models in AR

The product development process can be significantly improved by using virtual design models in augmented reality. The technology also supports the digital product presentation. At the same time, everyone involved in the process has access to digital processing.

With the help of AR, these prototypes come directly to the team members, regardless of where they are at the moment. They can be easily projected into your own environment using a smartphone or tablet. At present, use via these so-called smart devices is the common standard. In the future, smart glasses could ensure even more widespread use. If you want to learn more about the future of product development in combination with AR, we recommend this article.

A pioneering technology – even after the pandemic

Even after the pandemic, the use of digital, virtual prototypes with AR will continue to spread and become established. The efficiency of this solution can hardly be caught up with physically existing prototypes. In terms of production time and costs, conventional prototypes cannot keep up with their digital successors. In addition, many business trips are eliminated, material use and transport costs are significantly reduced. This not only protects the financial expenses of the company – it is also good for the environment.

Do you have further questions about augmented reality that the Mako-Technics team can answer? Please use our contact form and contact us at any time! We look forward to your message and the mutual exchange.

For other topics related to reverse engineering and AR, please visit our blog! This offers you a unique opportunity to obtain comprehensive information.

There are no comments