Reverse Engineering in Mold Making

Reverse Engineering in Mold Making

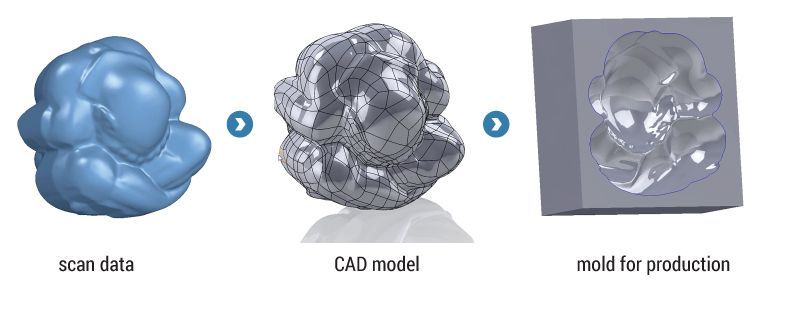

Reverse engineering is an important step to getting back at the CAD model of a finished part. If the actual engineering results from the 3D model to the finished product, it is the opposite for reverse engineering: from the products back to the 3D model.

There are different reasons for carrying out this process depending on the industry. For example, in the automotive sector, manually produced design studies are often scanned and converted into 3D models. In special vehicle construction, the manufacturers determine the exact dimensions of the chassis and other components because these are usually not available.

RE plays a rather disreputable role in the unauthorized replication of branded products. When pens or lawnmowers look deceptively similar to the originals, there is often reverse engineering behind them.

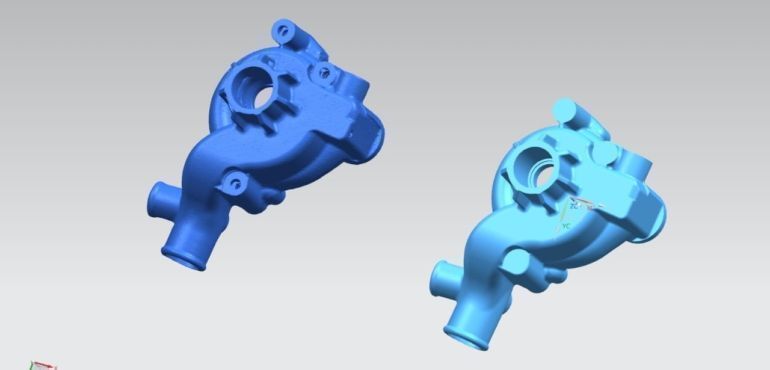

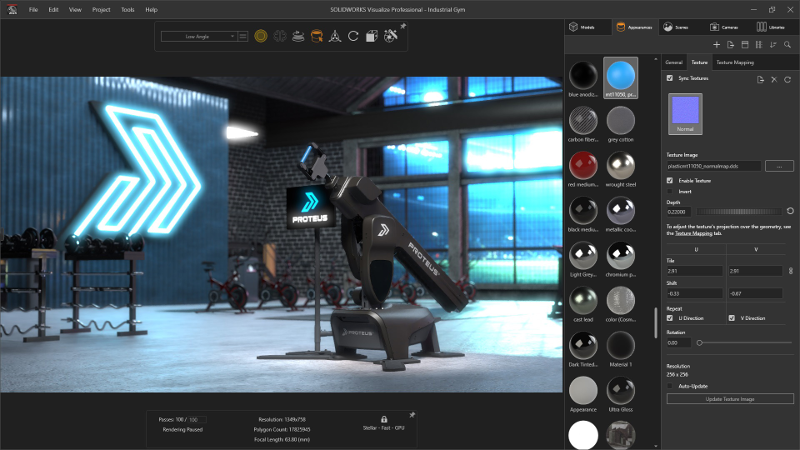

In tool and mold making, however, Reverse Engineering with Mako GmbH is used entirely for the benefit of customers and manufacturers. The first products that have just been manufactured are often compared with the CAD data to reveal deviations. We utilize the latest software to create high-precision molds with a quality surface finish for our clients.

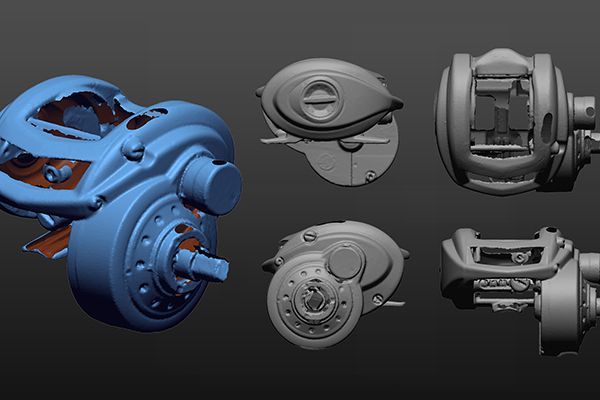

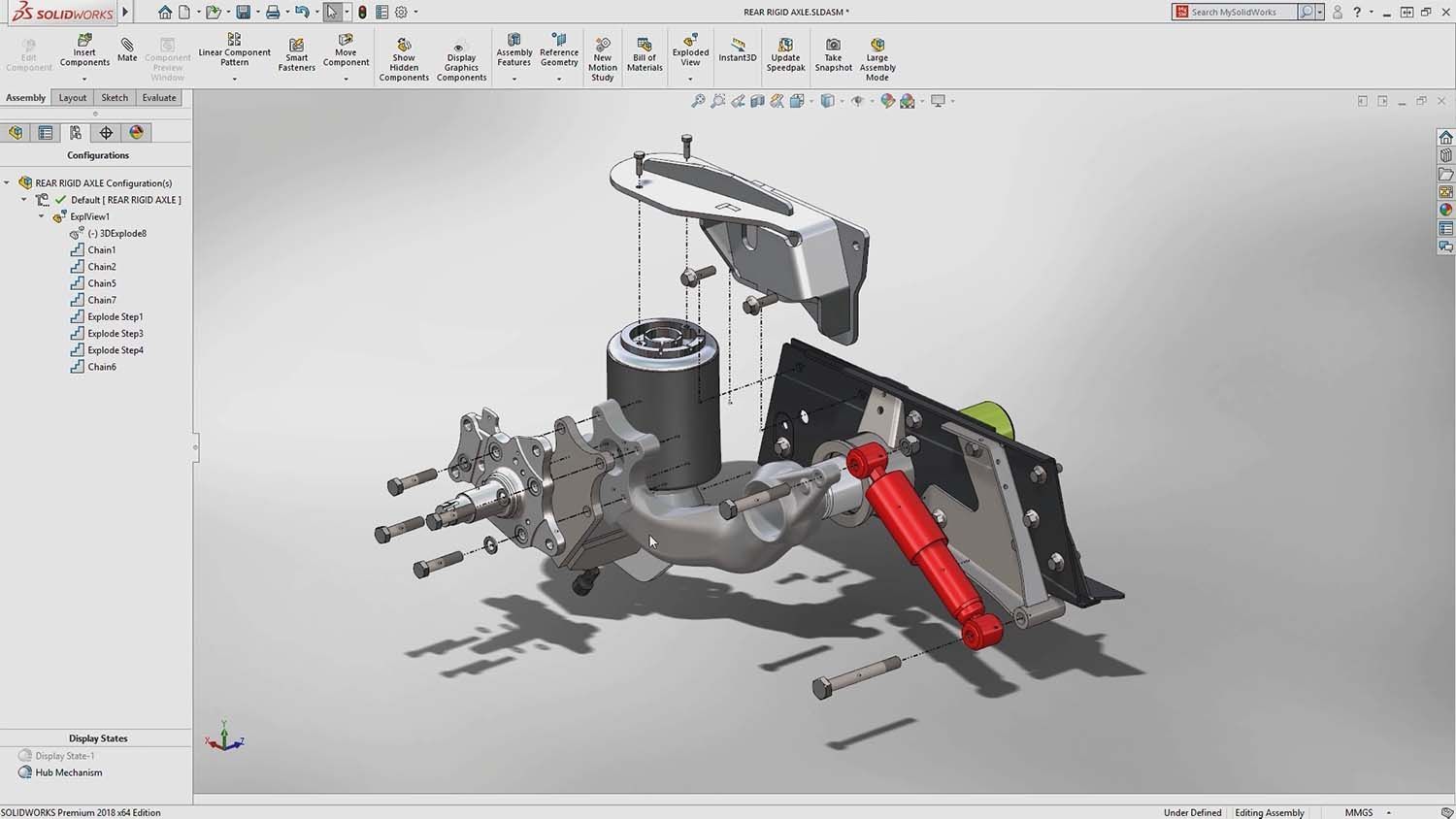

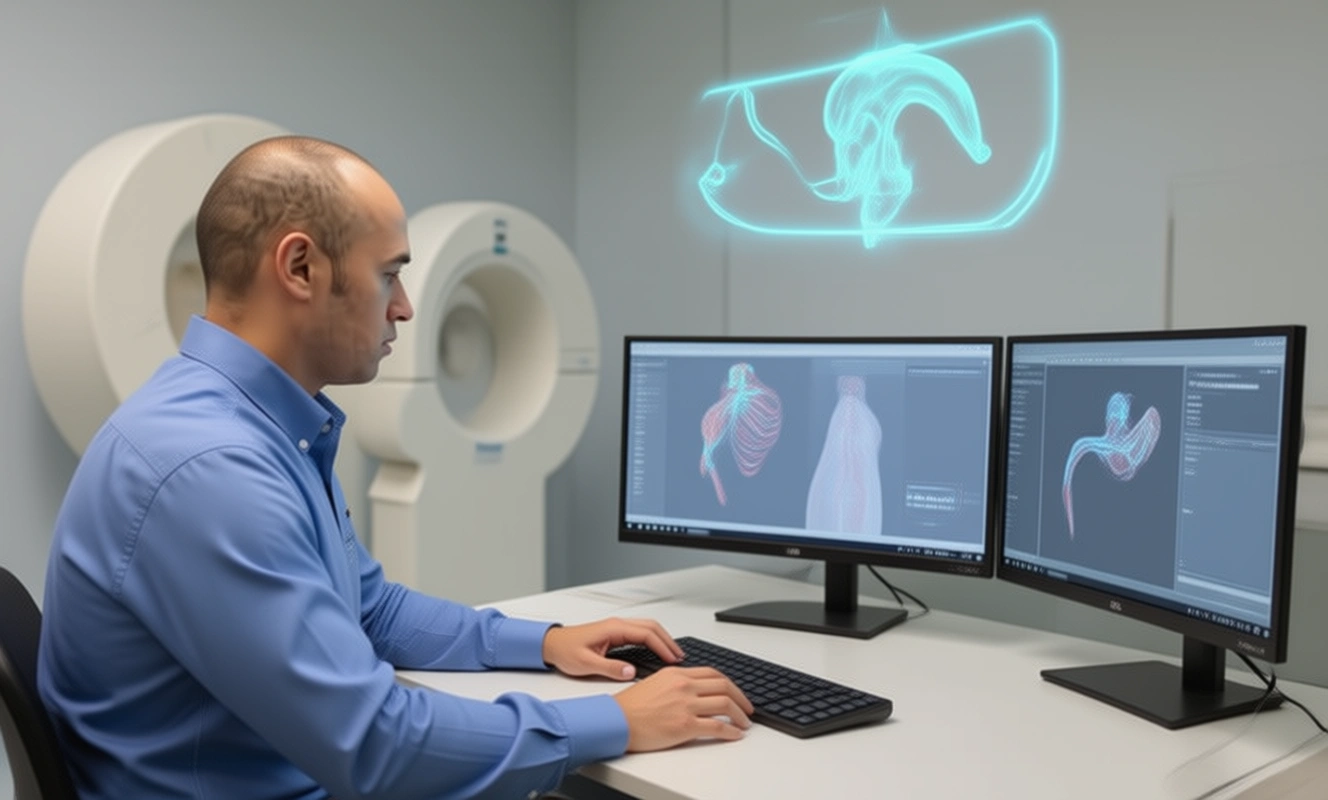

To obtain the measurement data of the initial samples, which are then processed using our software, three types of devices come into question: 3D scanners, coordinate measuring machines, and CT scanners. While coordinate measuring machines measure individual points, 3D and CT scanners always give us a point cloud as the measurement result. To use the point cloud, the RE data in the CAD system must be transmitted.

In reverse engineering in tool and mold making, we utilize the three concepts for using the measured 3D data:

- Modeling as mesh or triangular facets for comparison and analysis

- Targeted processing of the created network

- Conversion into a full-fledged 3D CAD model

With over 20 years of experience in Reverse Engineering, MAKO GmbH offers practical solutions to special processes like mold making. Contact us, and we will help you achieve the best workpiece.

There are no comments