Practical Solutions with Reverse Engineering and 3D Printing

Practical Solutions with Reverse Engineering and 3D Printing

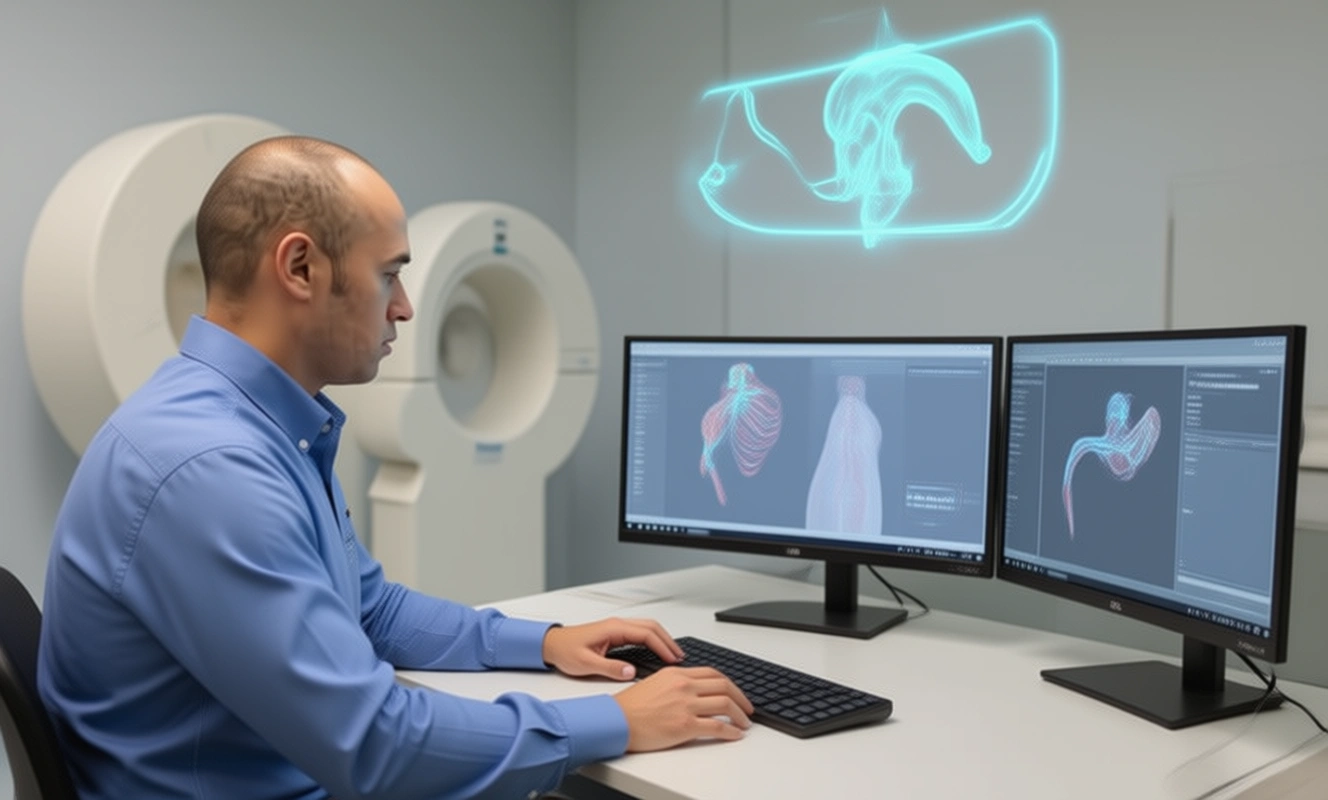

In this Blog article, Reverse Engineering Service expert Mako GmbH provides examples of how Reverse engineering and 3D printing are interlinked and can be used to make practical business solutions. How it increases speed and productiveness for businesses.

Reverse engineering and 3D printing has proven to be an essential part in a company’s development workflow. For example: A contract manufacturer routinely reverse engineers and 3D prints prototypes of aerospace legacy parts for more confident production. They use the high-precision, demonstrable prototypes for much more than just form and fit. Quite often companies rely on the prototypes to support engineering discussions with customers.

With new portable measurement solutions, a non-critical part can be reverse engineered, modeled, produced, inspected and installed with just three steps:

- Scan the part to collect reverse engineering data

- Perform a fit check using 3D printed prototype and

- Install the new part

For example, when parts for an older aircraft need to be replaced, oftentimes no spares, CAD data or original tooling are available. After years of use the original design specifications for the parts, such as duct work, may no longer fit as designed. In some cases, an originally designed part may have a design drawback that has been amended. In each case, reverse engineering and product realization provide practical ways for engineers to identify problems and apply recommended solutions. A part that would typically take eight to 16 weeks to create, can now be produced as a high-precision model in just a couple of days. The customer is then able to do a fit check using the model and approve production with confidence.

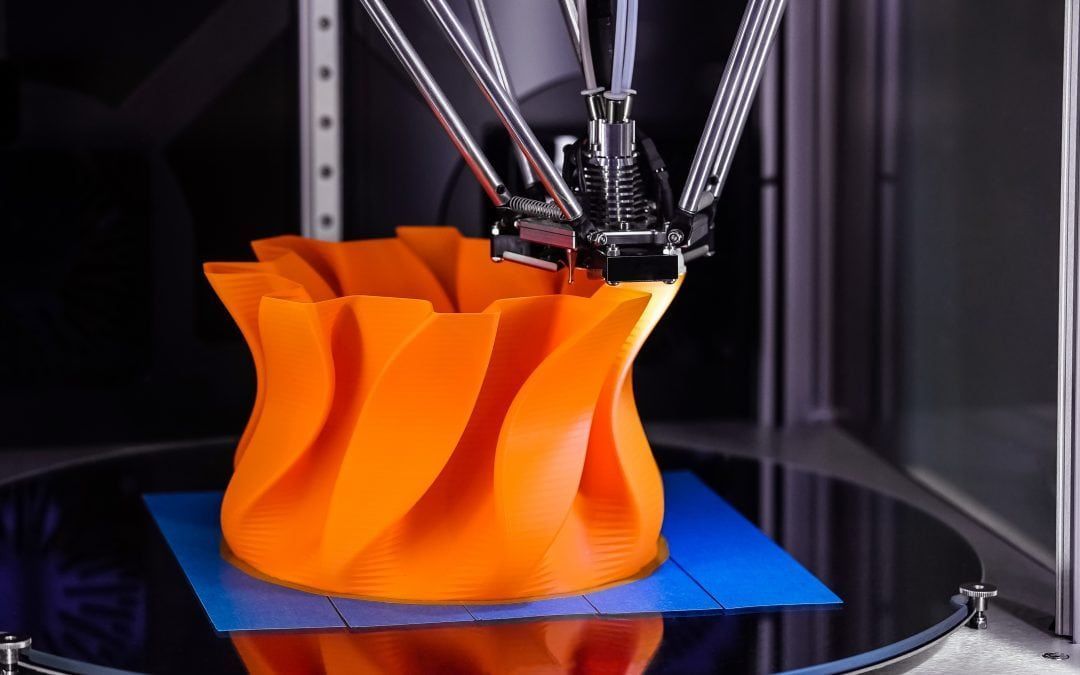

Electronic three dimensional plastic printer during work

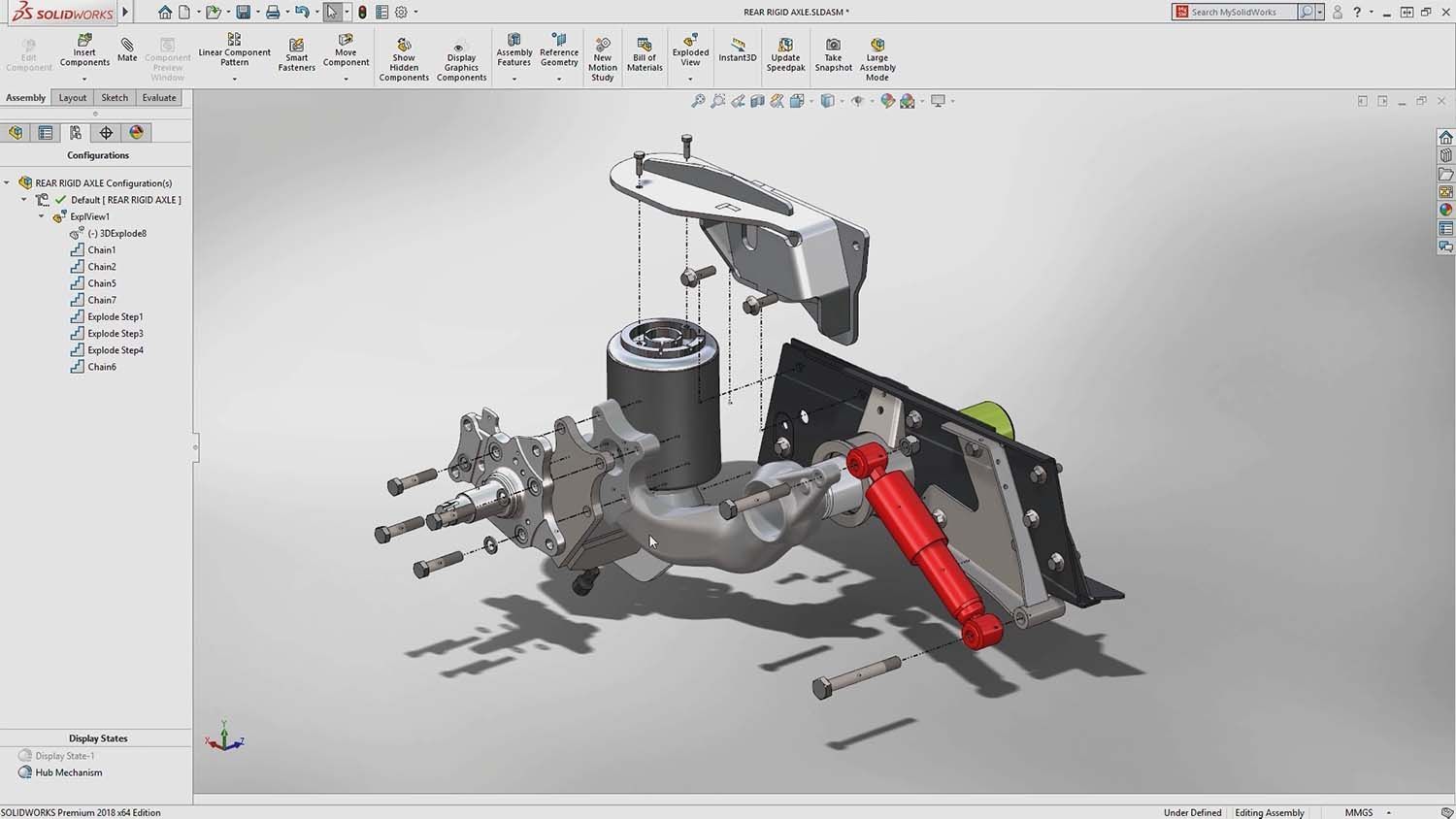

The process is straightforward. First the original part is disassembled and each component carefully reverse engineered using Reverse Engineering software. Depending on the environment, the data can be captured using a CMM or portable CMM with either a touch probe or laser scanner head.

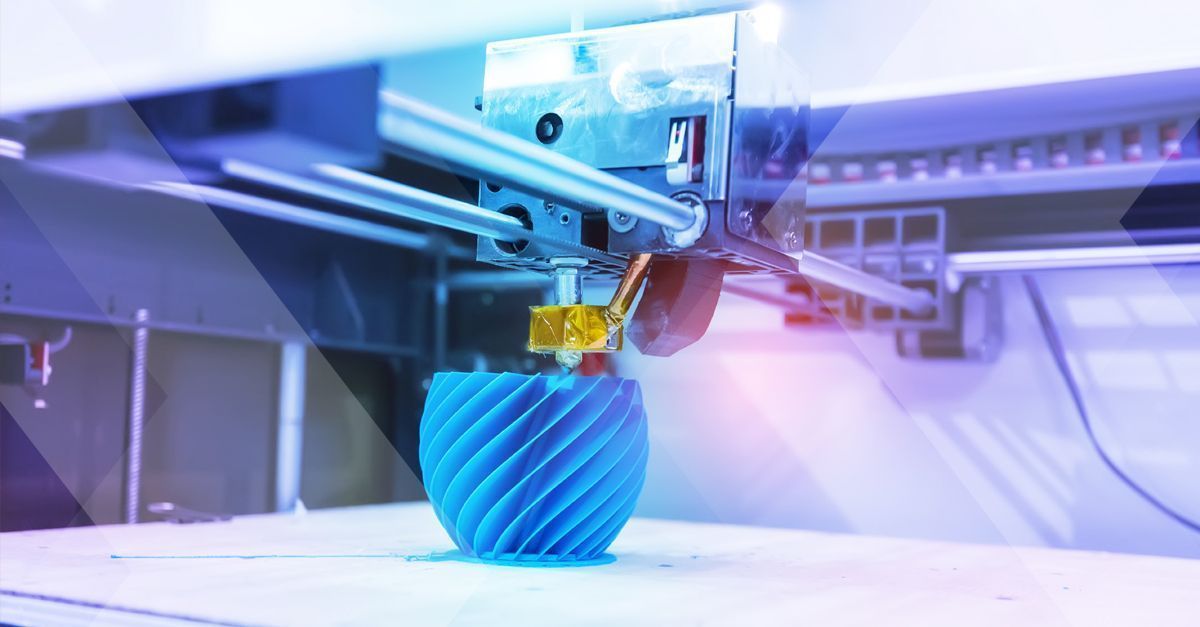

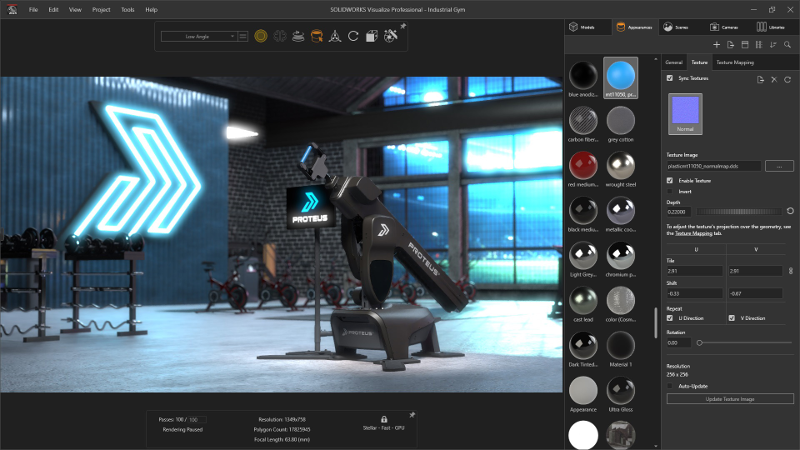

RE Software converts the captured point cloud data into STL mesh models suitable for 3D printing and again into 3D solid models for export to popular CAD formats. Design modifications are then made and final prototype components output to a 3D printer.

Following design review and approval, the 3D prototype can be used as a representative model for subcontractors involved in the manufacturing process, such as machining, welding, coating and final assembly.

If you want to explore more about Reverse Engineering, CAD software and how to master them check out our Blog Posts here or contact us here to get in touch with a Reverse Engineering expert!

There are no comments