Computer Aided Design for Industry 4.0

Computer Aided Design for Industry 4.0

The term “Industry 4.0” has been on everyone’s lips for a long time. What they have in common is the intelligent networking of machines and operational processes. Computer Aided Design, or CAD for short, makes an important contribution to this development. But how exactly does CAD help here? The Mako-Technics team addresses this connection in this article.

Do you need help quickly from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

Computer Aided Design for Industry 4.0: What is it about?

As described at the beginning, the term Industry 4.0 stands for intelligent networking within industry. In essence, this is about various processes that we would like to bring you closer to using various examples.

Several companies are often required to produce a single product. The digital networking of these different companies ensures that a more precise coordination and utilization of certain machines is possible. For the product development chain, intelligent networking can often increase the lifespan of a product. This ensures that products remain functional throughout their service life. The key point here is resource-saving production, which is made possible by optimal coordination between different companies.

Industry 4.0 can also make an important contribution to environmental protection and sustainability. Intelligent, perfectly coordinated logistics can avoid unnecessary movement of goods and significantly reduce transport routes.

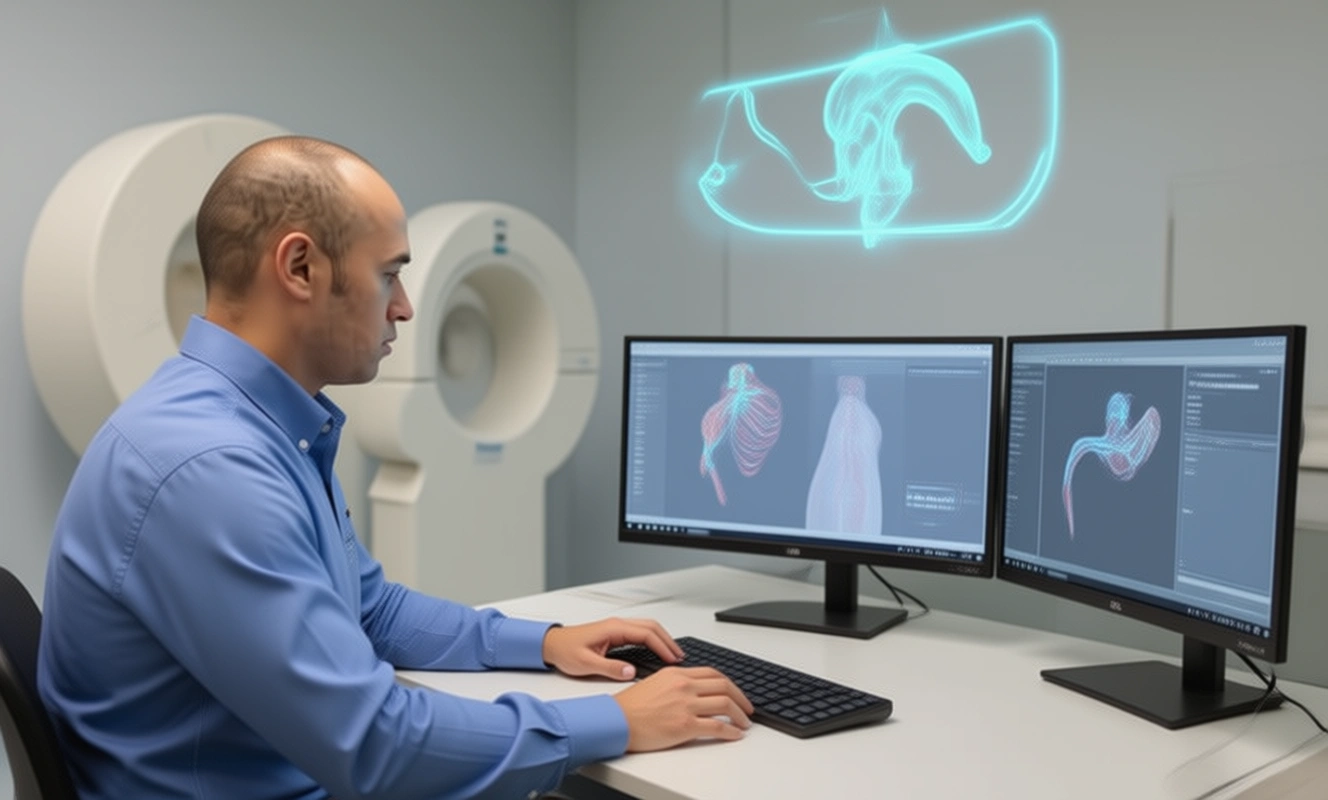

How does CAD contribute?

In the past few days, drawing on the drawing board was essential for product planning. Compared to today, this type of design is time-consuming and time-consuming. Often several people were involved in the process. However, technical progress and the development of computer-aided design have revolutionized our world of technology in this regard.

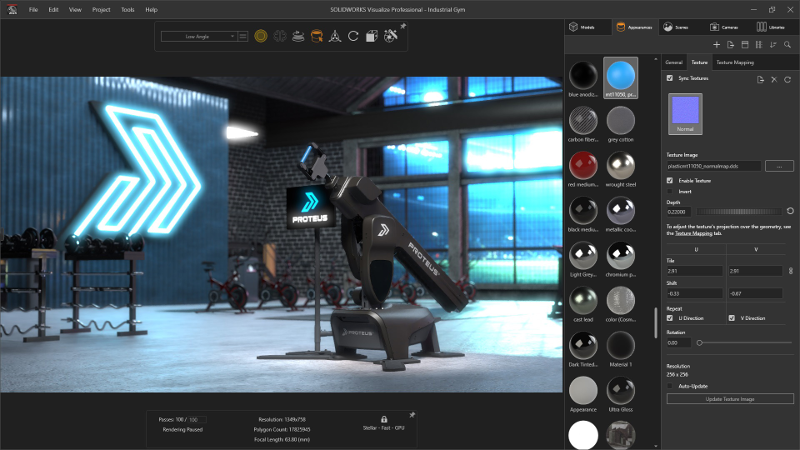

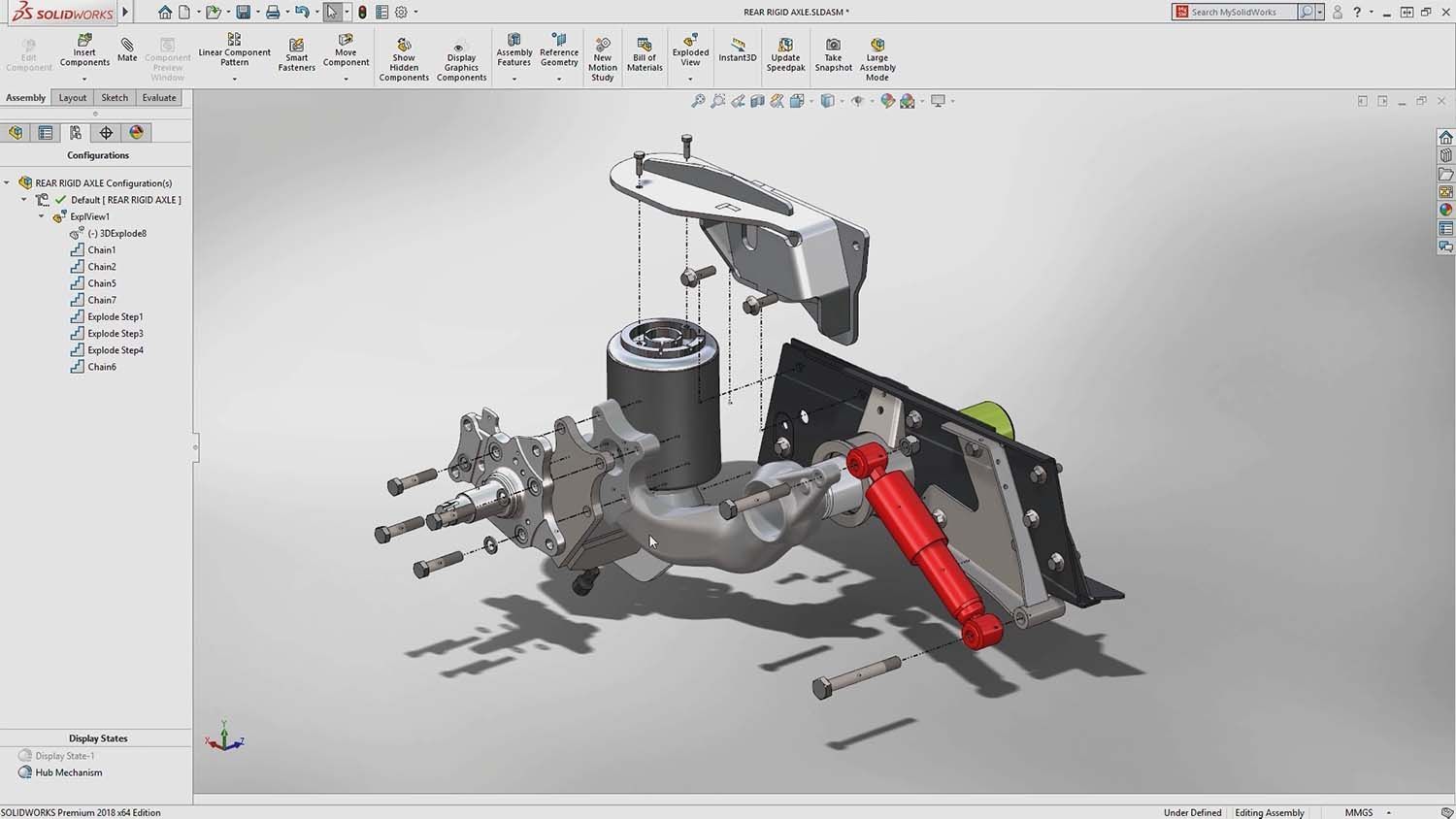

CAD software such as SolidWorks enables engineers and users to complete all steps digitally, from the first planning to the market-ready product. On the one hand, this saves a lot of resources, on the other hand, time is effectively saved. As a result, the development becomes more cost-effective. In addition, there are of course other advantages if prototypes are created purely virtually – for example, think about the advantages of today’s world that tasks to be done can be done anywhere at any time.

CAD thus contributes to making development processes more efficient and enormously supporting the ever more closely networked industry in streamlining processes.

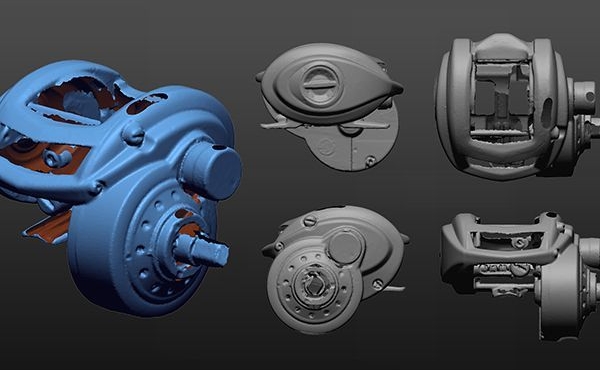

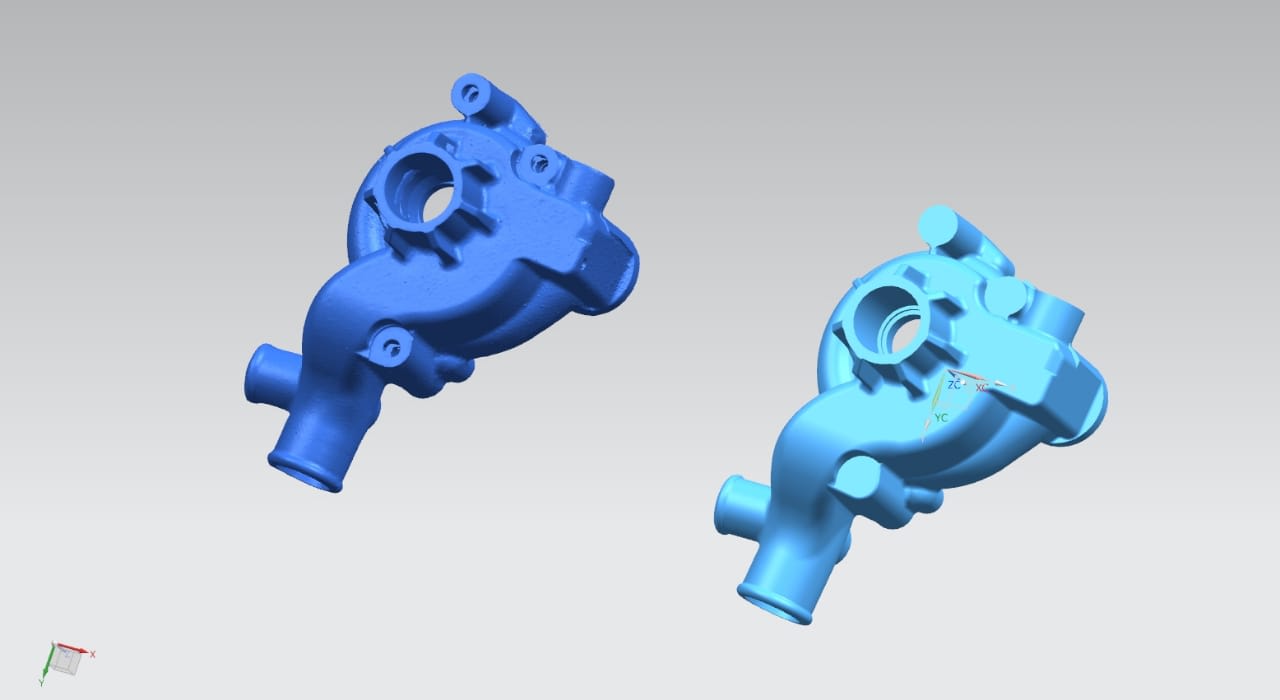

Reverse Engineering and Computer Aided Design

In principle, CAD is used in a wide variety of industries. Examples of this are product design, architecture, mechanical engineering and many more. The Mako GmbH team also relies on a wide variety of CAD software solutions. This is essential for our daily work. We offer professional reverse engineering paired with decades of experience – you too can benefit from our expertise and know-how.

Do you have further questions about us or about Computer Aided Design? Contact us anytime! We are happy to answer your questions and look forward to your message. If you would like to find out more about us, reverse engineering or the industry, please feel free to use our blog. There we will provide you with regular updates on new developments and topics.

There are no comments