Unlocking Automotive Reverse Engineering with 3D Scanning

Unlocking Automotive Reverse Engineering with 3D Scanning

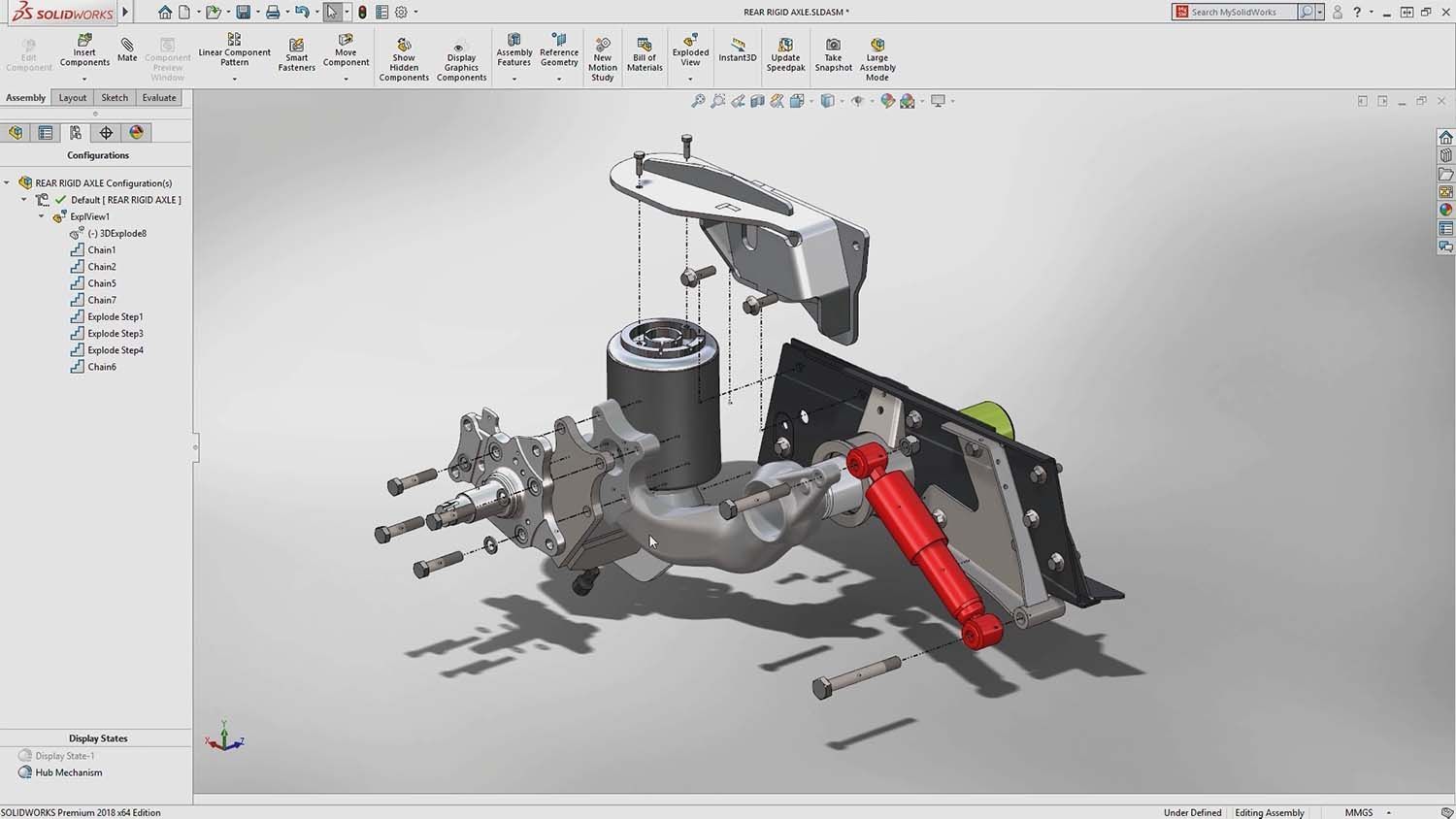

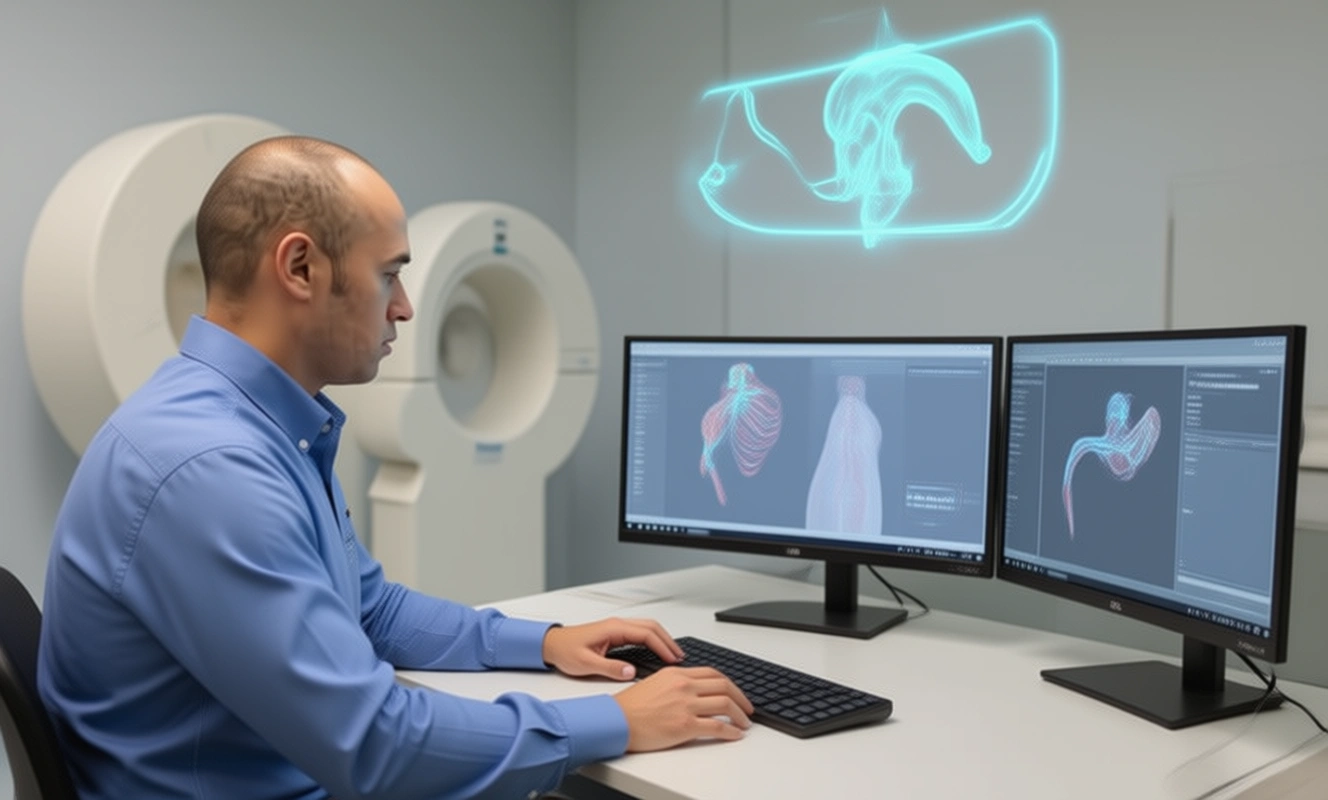

3D scanning is revolutionizing the field of automotive reverse engineering, providing engineers and designers with unparalleled precision and efficiency. This technology allows for the quick digitization of physical parts into digital formats, facilitating an array of applications from prototyping to quality control.

What Is 3D Scanning Used For?

The uses of 3D scanning in the automotive sector are extensive. Here are a few key applications:

- Prototyping: Rapidly create prototypes that mirror existing components.

- Quality Control: Ensure that manufactured parts meet design specifications by comparing them to scanned data.

- Restoration: Accurately recreate vintage car parts that are no longer in production.

- Customization: Tailor vehicle parts for unique modifications or enhancements based on customer preferences.

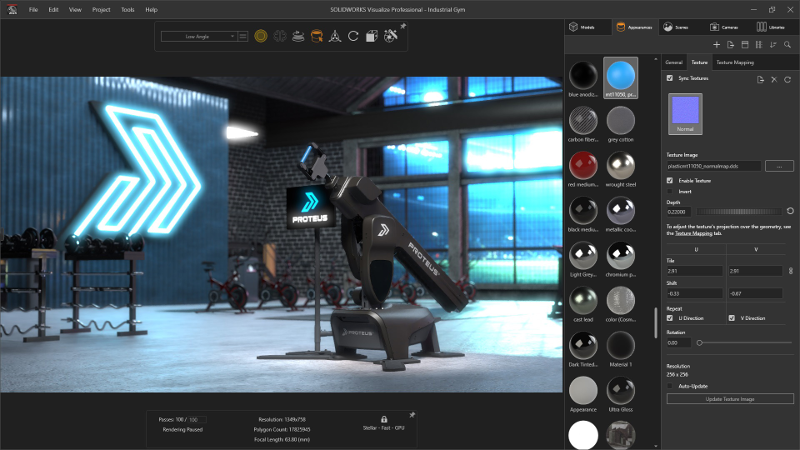

The Benefits of CAD Scanning in Automotive Projects

When it comes to converting physical components to digital files, CAD scanning plays a crucial role. It streamlines the workflow and enhances collaboration among teams. Here’s how CAD scanning benefits automotive reverse engineering:

- Accuracy: Captures minute details that might be overlooked in traditional measurement methods.

- Speed: Accelerates the data collection process, enabling quicker project timelines.

- Easier Modifications: Facilitates easy alterations to designs based on initial scans without starting from scratch.

Navigating the Challenges of Traditional Methods

Automotive engineers often face challenges when relying solely on traditional measurement techniques. These methods can be time-consuming and prone to human error, leading to costly mistakes. 3D scanning eliminates these issues by providing rapid and reliable data capture, allowing teams to focus on innovation rather than remediation.

The Cost-Effectiveness of 3D Scanning

A common question arises: “How much does a 3D scan cost?” While pricing can vary depending on the complexity of the part and the technology used, investing in 3D scanning typically results in significant long-term savings. By reducing material waste, minimizing errors, and speeding up production times, companies can see a favorable return on their investment.

The Future of Automotive Reverse Engineering with 3D Technology

The integration of 3D scanning technology into automotive reverse engineering is not just a trend; it’s becoming a necessity for staying competitive. As vehicles evolve with more intricate designs and technologies, having precise measurements becomes critical. Embracing this technology positions companies at the forefront of innovation.

Your Next Steps Toward Precision Engineering

If you’re ready to enhance your automotive projects through advanced techniques like 3D scanning, now is the time to act. Explore how implementing this technology can transform your approach to reverse engineering, ensuring accuracy and efficiency across your workflows. The future awaits those who adapt swiftly!

How can we help you?

Do you have further questions about us or reverse engineering? Contact us anytime! We are looking forward to your message.

Would you like to learn more about exciting reverse engineering topics? Please visit us on YouTube! There we regularly provide videos on exciting topics.

There are no comments