Top Reverse Engineering Tools for Solidworks Users

Top Reverse Engineering Tools for Solidworks Users

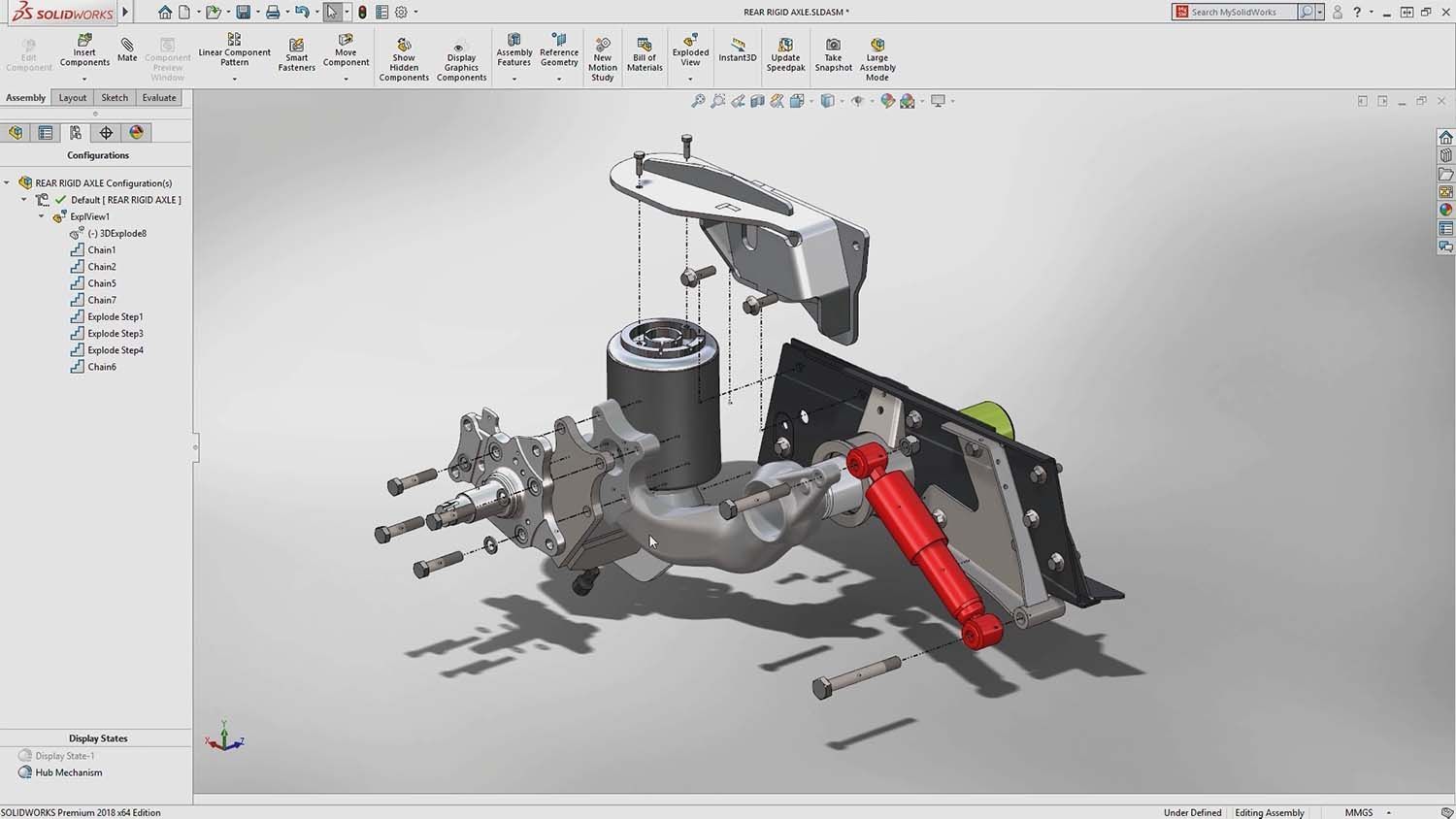

For Solidworks users looking to enhance their design capabilities, leveraging reverse engineering tools can significantly elevate your 3D modeling experience. Whether you’re aiming to recreate existing designs or refine your CAD applications, the right software can streamline your workflow and improve accuracy.

Understanding Reverse Engineering Tools

Reverse engineering involves analyzing a product to understand its components and functionality. The best reverse engineering tools not only facilitate this process but also integrate seamlessly with Solidworks. Here’s how they can benefit your projects:

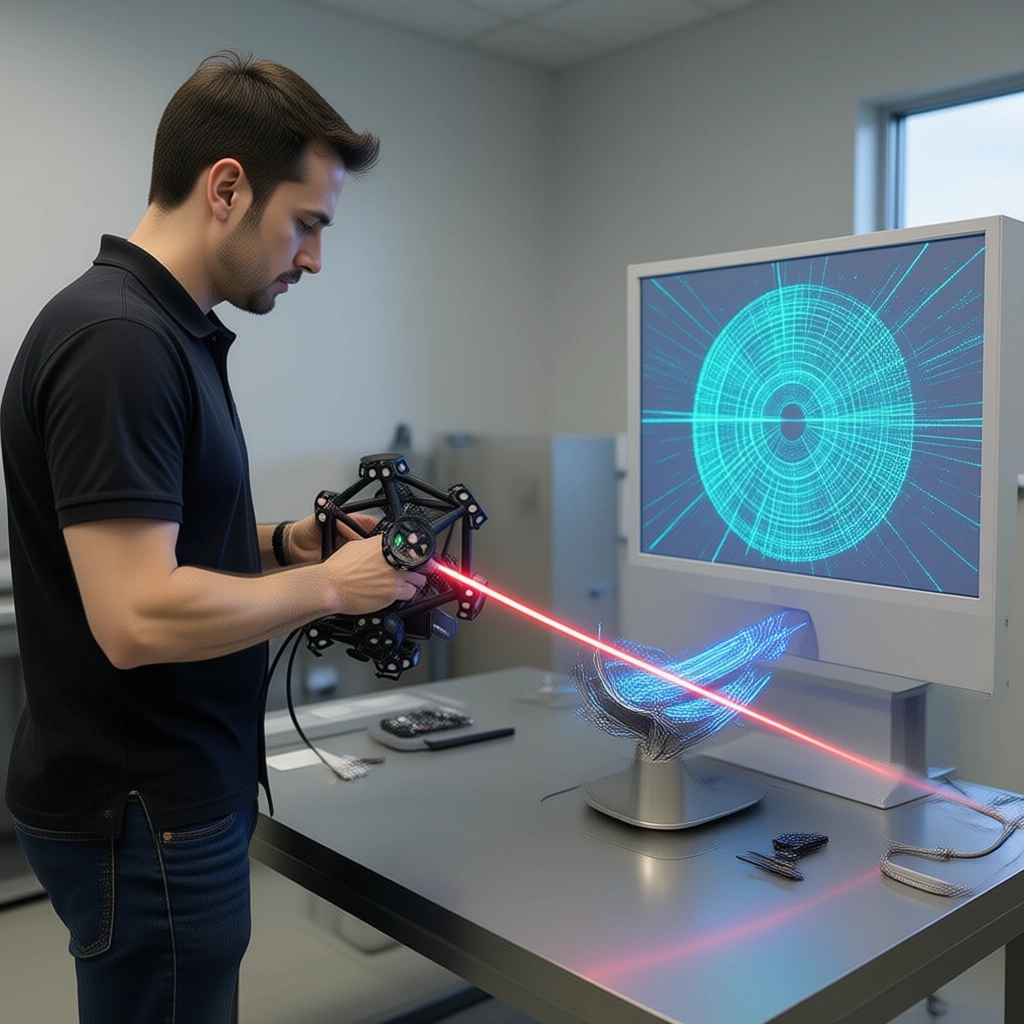

- Enhanced Accuracy: Capture intricate details of physical objects through 3D scanning.

- Efficient Workflow: Speed up the design process by importing scanned data directly into your CAD software.

- Improved Collaboration: Share models easily among team members or with clients for feedback and adjustments.

Top Tools for Solidworks Users

Choosing the right reverse engineering tools can make all the difference in your projects. Below are some highly recommended options that complement Solidworks effectively:

1. Geomagic Design X

This powerful tool excels at converting mesh data from 3D scans into parametric models within Solidworks. Geomagic Design X offers robust features for mesh repair and simplifies complex workflows, making it a top choice for professionals involved in 3D modeling.

2. SOLIDWORKS ScanTo3D

An integrated feature within Solidworks, ScanTo3D allows users to import and convert 3D scan data directly into Solidworks files. This tool is perfect for creating precise CAD models from scanned objects, ensuring that your designs maintain high fidelity to the original forms.

3. Rapidform XOR

This versatile reverse engineering software aids in transforming point cloud data into editable 3D models. With its user-friendly interface, Rapidform XOR supports various file formats and provides advanced mesh repair capabilities, making it ideal for detailed design work.

Key Features to Look For

When selecting reverse engineering software, consider these essential features that enhance functionality:

- Mesh Repair Capabilities: Ensure that the tool can handle imperfections in scanned data.

- User-Friendly Interface: A straightforward layout allows for easier navigation and quicker learning curves.

- Solidworks Integration: Look for tools that natively support Solidworks file formats and workflows.

- Parametric Modeling Support: This feature enables easy adjustments to designs without starting from scratch.

The Benefits of Using Reverse Engineering Tools

The integration of reverse engineering tools into your design process offers several advantages:

- Saves Time: Quickly replicate or modify existing designs without extensive manual input.

- Cuts Costs: Reduce material waste by accurately capturing dimensions before production.

- Paves the Way for Innovation: Use existing products as a foundation to inspire new ideas and enhancements.

Your Next Steps in Reverse Engineering

If you’re ready to take your Solidworks projects to the next level, consider incorporating one or more of these top reverse engineering tools into your workflow. By doing so, you’ll not only enhance your 3D modeling efficiency but also ensure that your designs meet industry standards and client expectations.

The world of CAD applications is ever-evolving, and staying updated with the latest tools will keep you competitive in the field of design. Explore these options today to unlock new potential in your projects!

How Can We Help You?

Do you have further questions about us or reverse engineering? Contact us anytime! We look forward to your message.

Would you like to learn more about exciting reverse engineering topics? Please visit us on YouTube! There we regularly provide videos on exciting topics.

Interested in Augmented Reality (AR) solutions? Learn more about our AR services on ar-4u.com.

There are no comments