Reverse Engineering of Organic Shapes

Reverse Engineering of Organic Shapes

Objects that are based on organic forms in nature are referred to as organic parts. They are often characterized by dynamic curves and powerful curves. In principle, they are technically not easy to understand or measure. The measurement of such shapes is therefore particularly difficult. A replica of such objects, for example for optimization purposes or in the sense of replacement products, quickly becomes a challenge. Classic measurement forms quickly reach their limits here. At this point, Mako-Technics appears as a problem solver. Overcoming this challenge is not a problem for our engineers. In this post, we will go into more detail about the reverse engineering of organic shapes. We would like to pass on our experience and expertise to you.

Reverse Engineering of Organic Shapes: DesignX and Catia

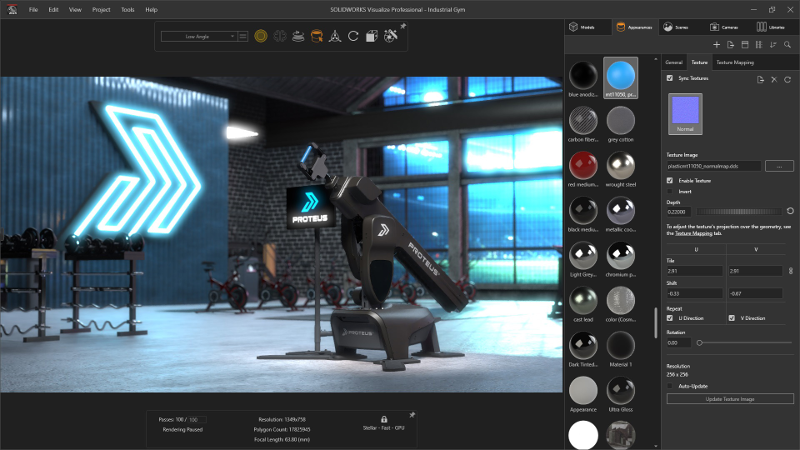

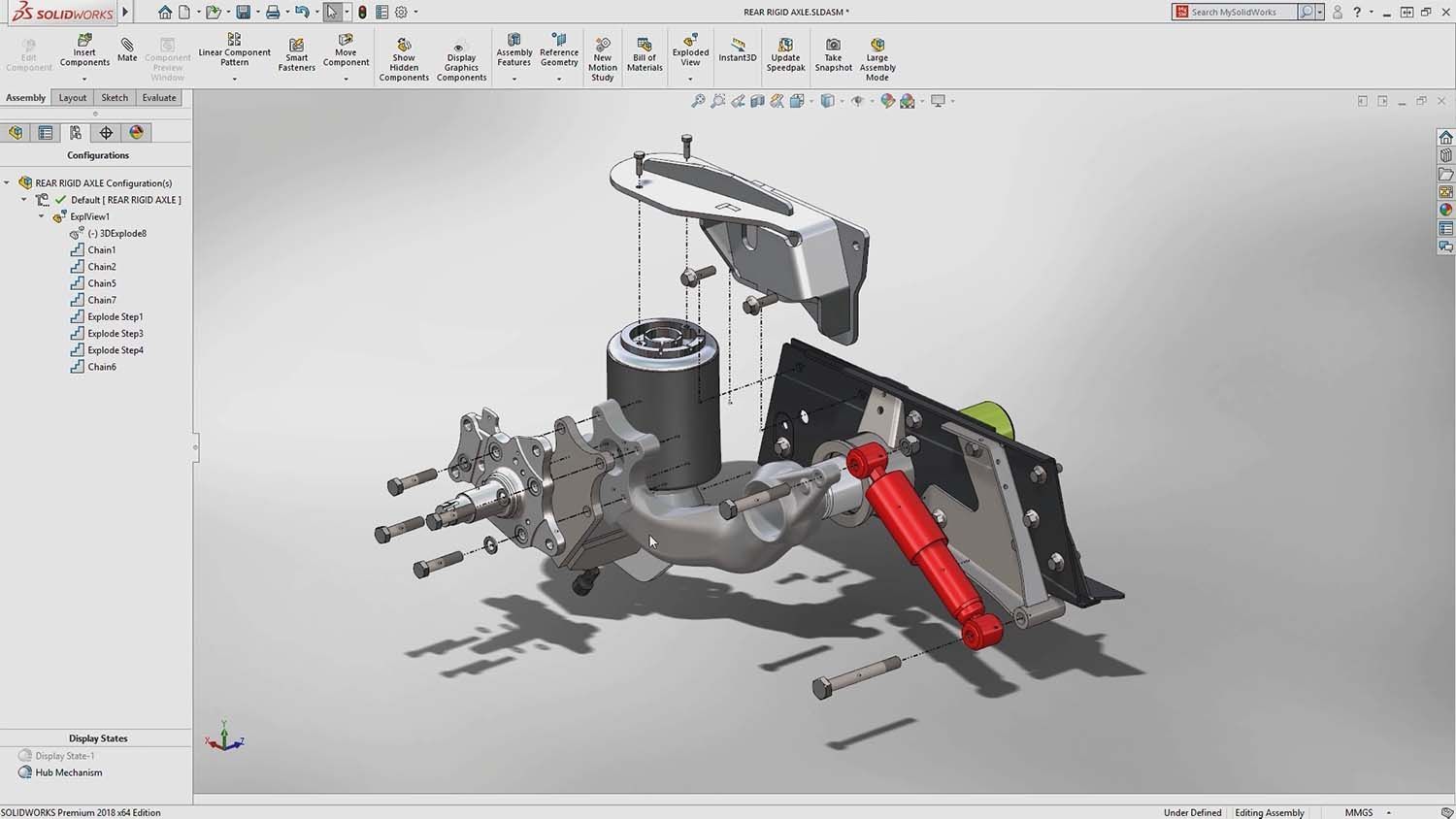

The experts at the Reverse Engineering Service work with a wide variety of software. Our engineers always use the most appropriate one for the particular project. For remodeling organic shapes, we recommend using DesignX and Catia. We’ll go into these two types of software below. We’ll explain why we use them and how they help us with organic shapes.

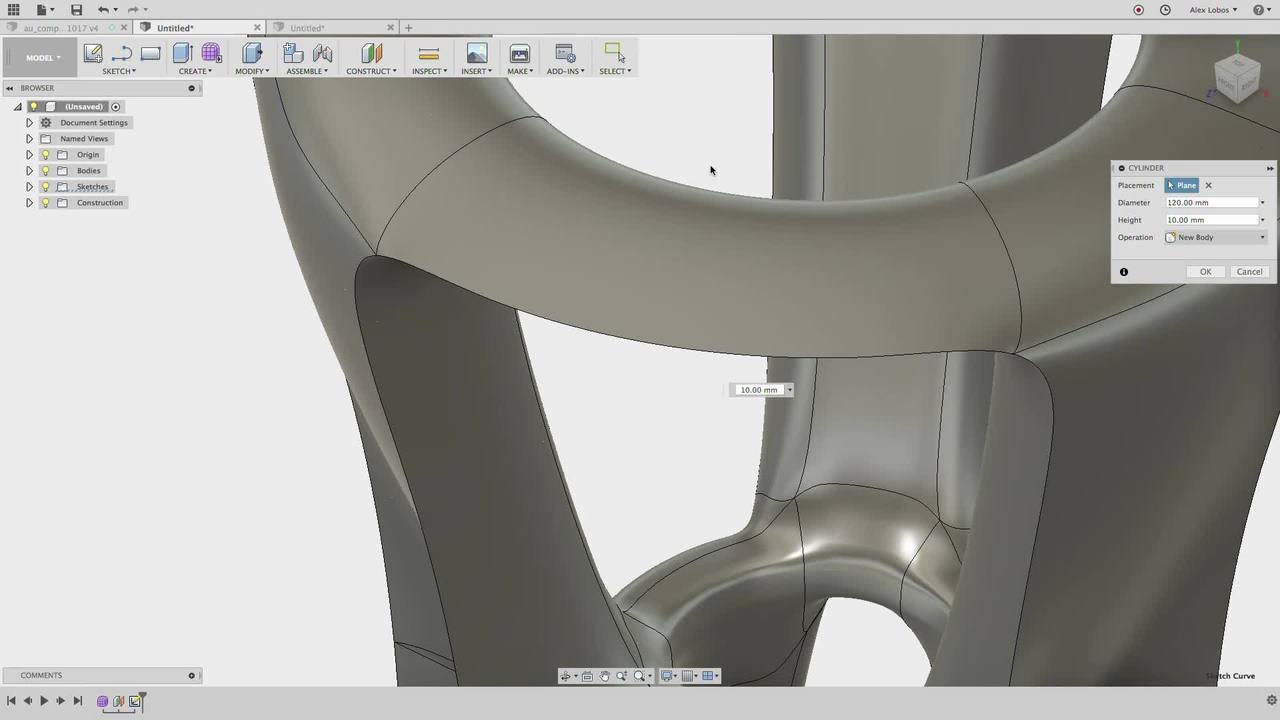

With Geomagic DesignX we can reverse engineer physical parts into digital parametric CAD models. We are very familiar with the program. It has proven to be extremely precise in processing point clouds in numerous projects. We know how to take full advantage of DesignX’s capabilities to develop the best 3D model. DesignX enables fast and precise work. It is powerful and flexible at the same time. The Mako-Technics team therefore relies on this program for reverse engineering of organic surfaces.

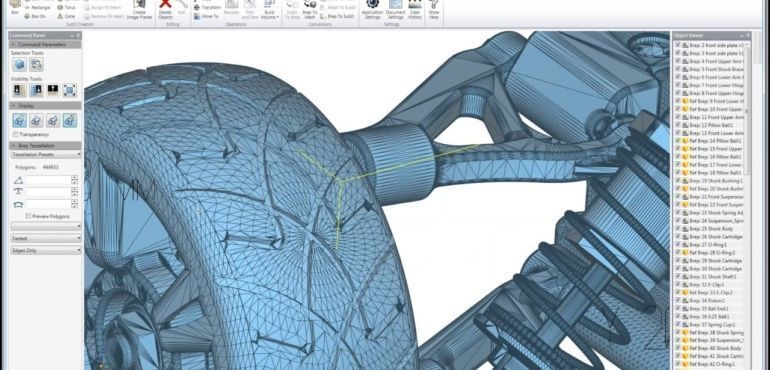

Catia is a complete software suite that includes CAD, CAE and CAM. Catia is currently on version 6. The software is a leader in the field of computer-aided engineering solutions. We use them to predict the CAD models quickly and precisely. It contains various tools that make it possible to design a product as well as to improve existing development processes. Catia enables digital prototyping. Including analysis and simulation for the design and validation of the functional quality of a product. For the Mako GmbH team, Catia has become an indispensable partner.

Organic Parts with Mako-Technics

As you can see, the measurement and digital dismantling of organic surfaces is child’s play with Mako-Technics. Our engineers attach great importance to compliance with German quality standards. Our customers appreciate our quality Made in Germany. Set the course with us towards successful projects. Contact us anytime. We are looking forward to your message.

There are no comments