Reverse Engineering: Make New from Old

Reverse Engineering: Make New from Old

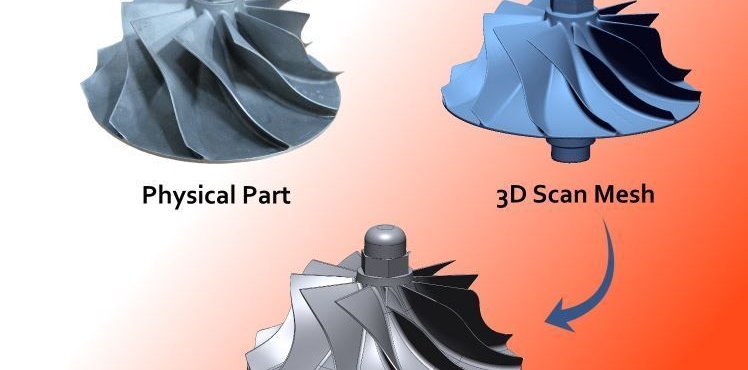

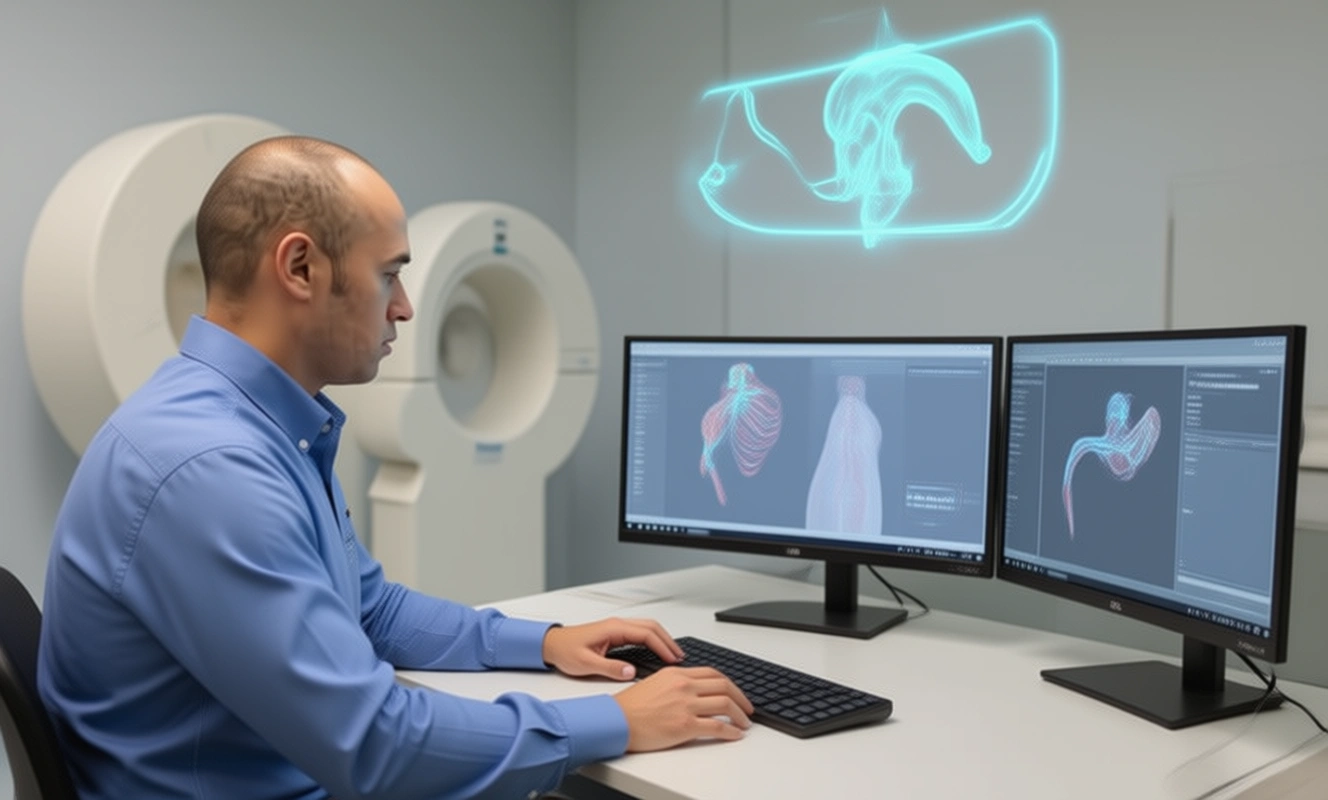

Reverse engineering allows an object or component to be replicated. This means that an object, for example a single part of a technical product, is scanned, digitized and converted into an accurate 3D CAD model through the process of reverse engineering, which then enables re-production. Many people are of the opinion that this process would only be possible with an externally almost undamaged object. But far from it – our service can also be used to obtain precise data for new parts from defective, worn or old parts. RE turns old into new and, above all, high-quality. Find out in this article how we can help you to generate precise CAD data for new and higher-quality products from old components and objects.

Need quick help from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

Reverse Engineering turns old into new: Many areas of Application

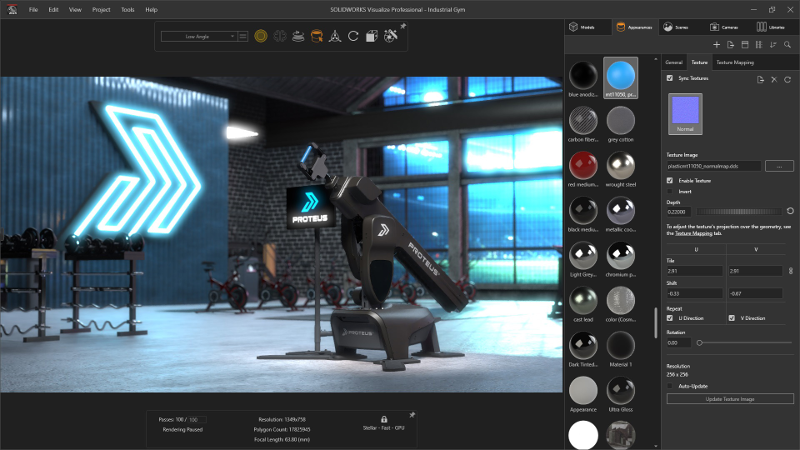

The areas of application of reverse engineering are extremely diverse. For example, our service is often used in production areas. But quality management and additive manufacturing are also important areas of application for our service. If you are interested in other applications, you are welcome to find out more about them here.

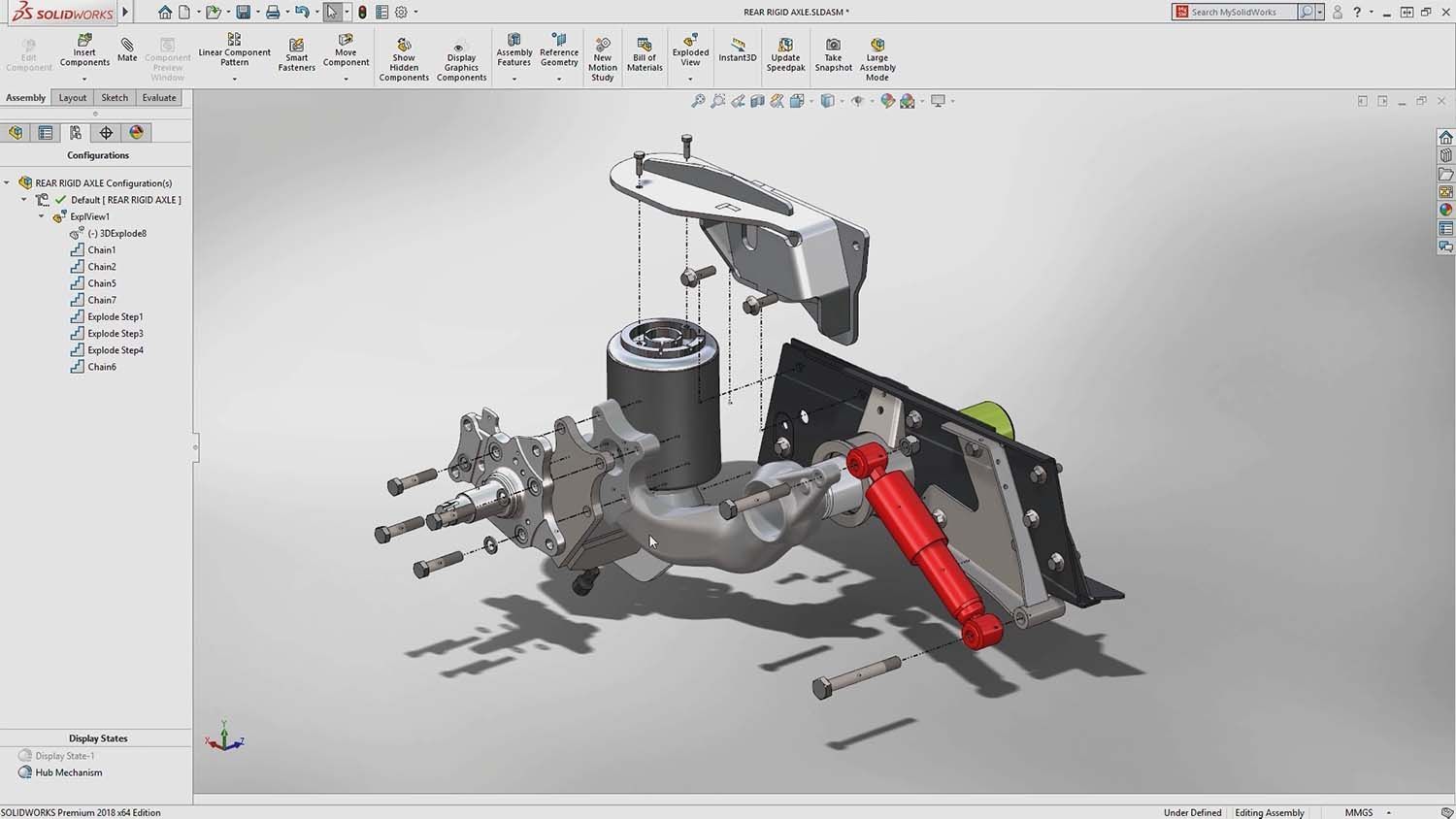

In the course of repairs or replacement intervals of various components, reverse engineering has become an important tool in the industrial age. In many cases, the required parts are no longer available. Or they are required with such regularity that it is worth having a precise CAD data set. Then to make them yourself.

Even worn parts are no problem

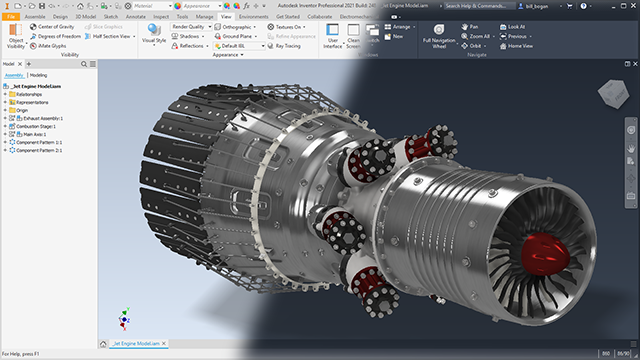

The service provided by Mako GmbH works in exactly the opposite way to conventional production. We start with a finished product or an individual component, digitize it with a 3D scan and generate a precise 3D CAD data set through our reverse engineering process. As already mentioned, we help companies in this way, for example, to supply their machines with spare and wear parts. In this way we enable a longer service life and cost-effectiveness of devices and machines.

RE has proven to be a multifunctional tool over time. Because even in the case of very old or even worn out components, our service can often make it possible to replace them without any problems. Do you have an old or worn component that we can digitize and refurbish to provide you with the required CAD model? Then contact us at any time! Together we will find a solution to your problem.

Would you like to learn more about us, reverse engineering or other topics? Visit our blog for this! This offers you a comprehensive information platform with regular new topics and articles.

There are no comments