Reverse Engineering in Toolmaking

Reverse Engineering in Toolmaking

An important area of application for reverse engineering is tool and mold making. Our service helps in this area to improve and optimize production tools. Here, RE refers to the conventional production process in reverse order: from the finished product back to the CAD model. In this article, the Mako GmbH team explains how and why reverse engineering offers effective solutions, especially in the area of mold and tool construction.

Need quick help from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

Reverse engineering in mold and tool making: Acquiring measurement data

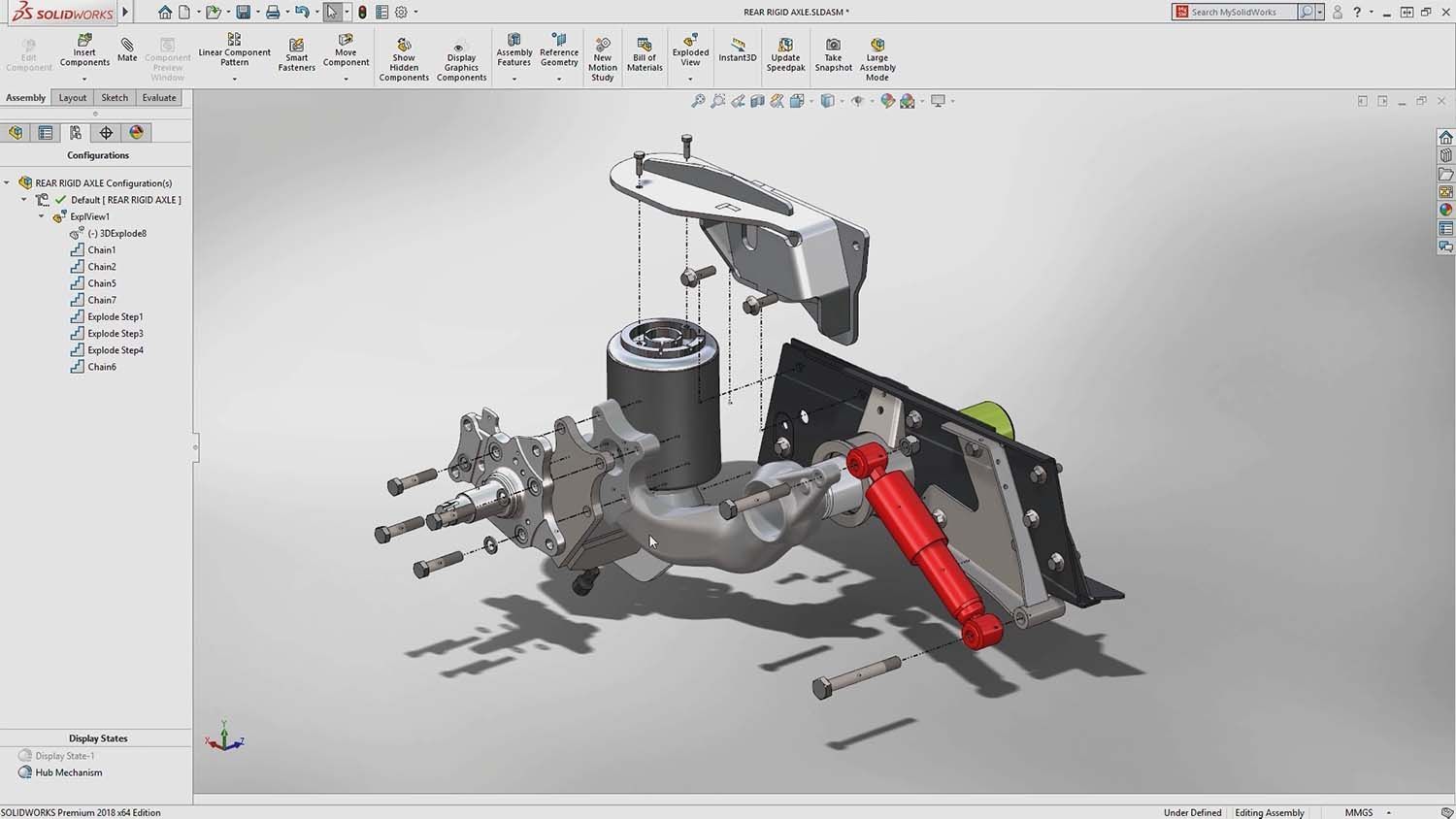

In many cases, our service is used when it comes to comparing manufactured products with their CAD data. In mold making, for example injection molding or sheet metal forming, there are often deviations. The reason for this are problems caused by shrinkage or delay. However, if changes are made to some parameters, these deviations and the associated test cycles can be reduced to a minimum.

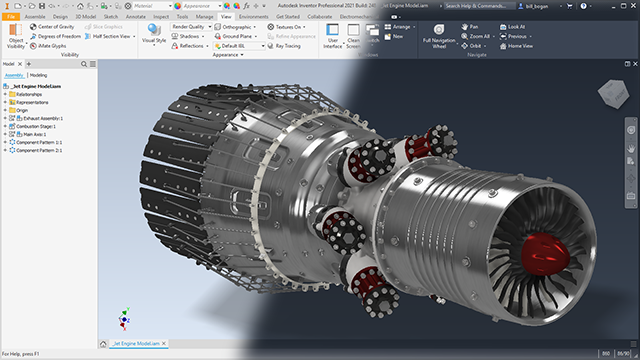

The most commonly used devices for reverse engineering today are 3D scanners. Compared to other measuring methods, they are quite cheap to buy. They also impress with their very high precision and also work extremely quickly. After the objects have been digitized, 3D scanners provide us with a highly precise point cloud, which is where our actual service begins.

Tip: Follow us on LinkedIn and never miss a post again! We would be happy to welcome you as a follower.

Precise comparison between the original CAD model and real data

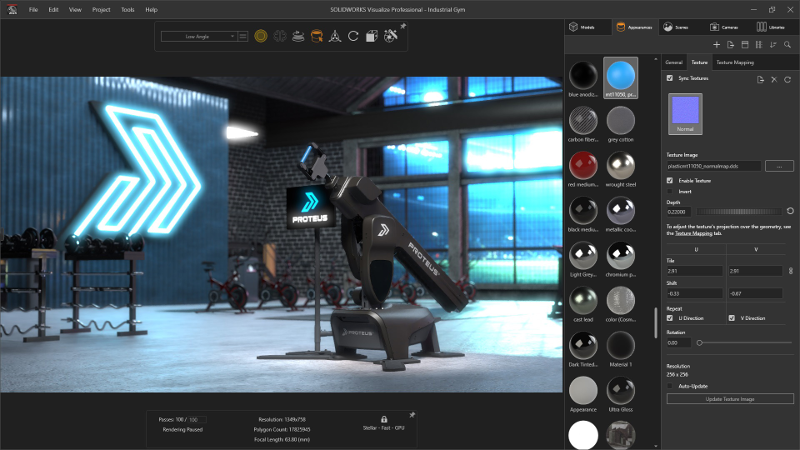

Once we have scanned the respective objects, our actual reverse engineering process follows. During this, we convert the data obtained from the scan into a volume-compatible CAD model. In this way, the current data can then be compared with the original plans. Deviations become visible and corrections can be initiated.

Reverse engineering: versatile areas of application

Reverse engineering not only offers a variety of solutions in tool and mold making. The areas of application of our service are enormously diverse and hardly limited in their number. Do you have a product or component for which you need a precise 3D CAD model? Contact us anytime! We look forward to your inquiry and will be happy to advise you.

Would you like to find out more about reverse engineering in connection with tool and mold making? Visit our blog for this! In this we regularly provide you with new topics and information about the industry.

There are no comments