Reverse Engineering: Areas of Application

Reverse engineering: Areas of Application

Reverse engineering reverses the conventional production process exactly. The service provided by Mako GmbH starts with existing products or components and ends with construction data. The development process is simply turned upside down. In this article, the Mako-Technics team will explain the areas of application for which reverse engineering offers enormous advantages.

Do you need help quickly from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

Areas of Application of Reverse Engineering: It all started in Mechanical Engineering

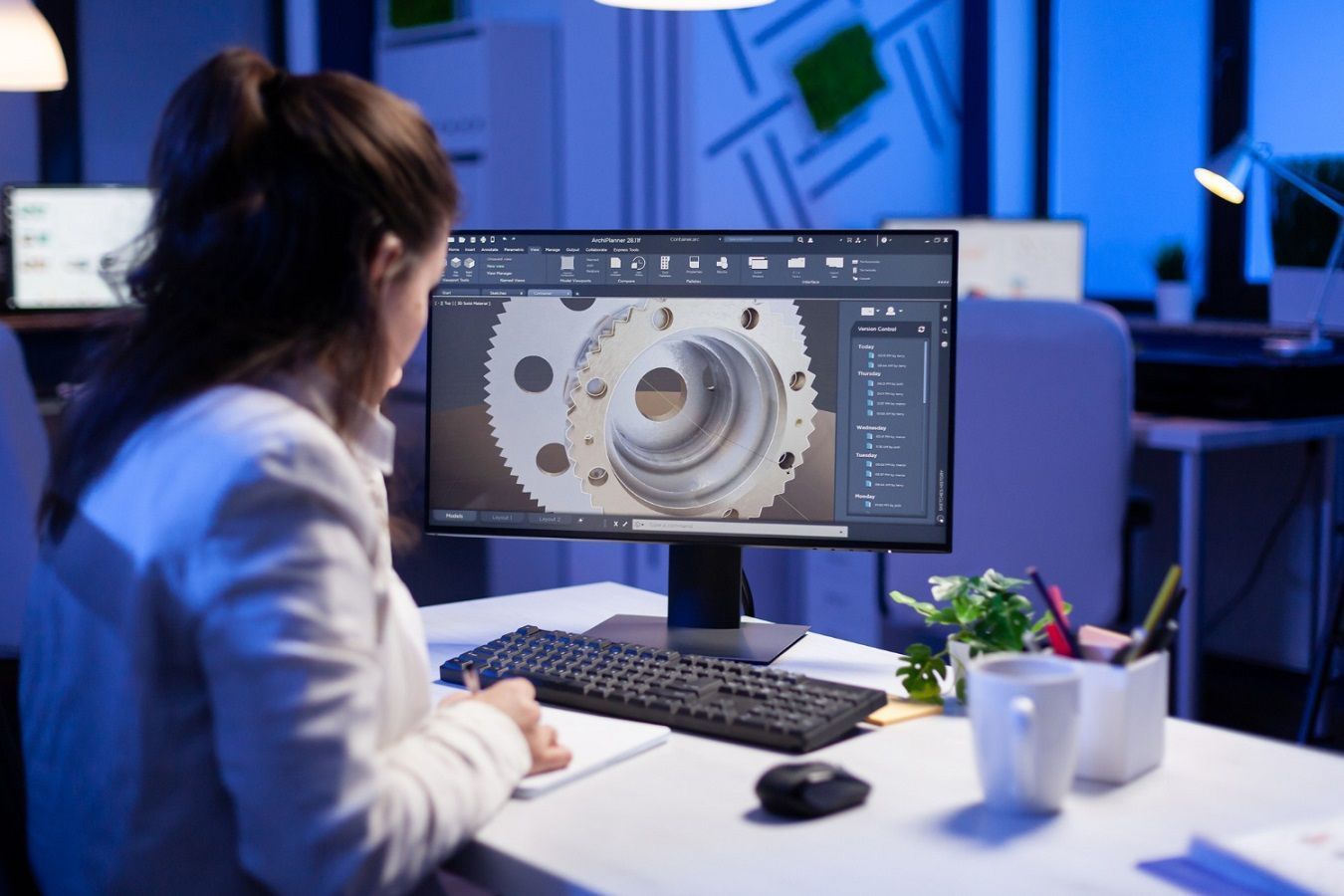

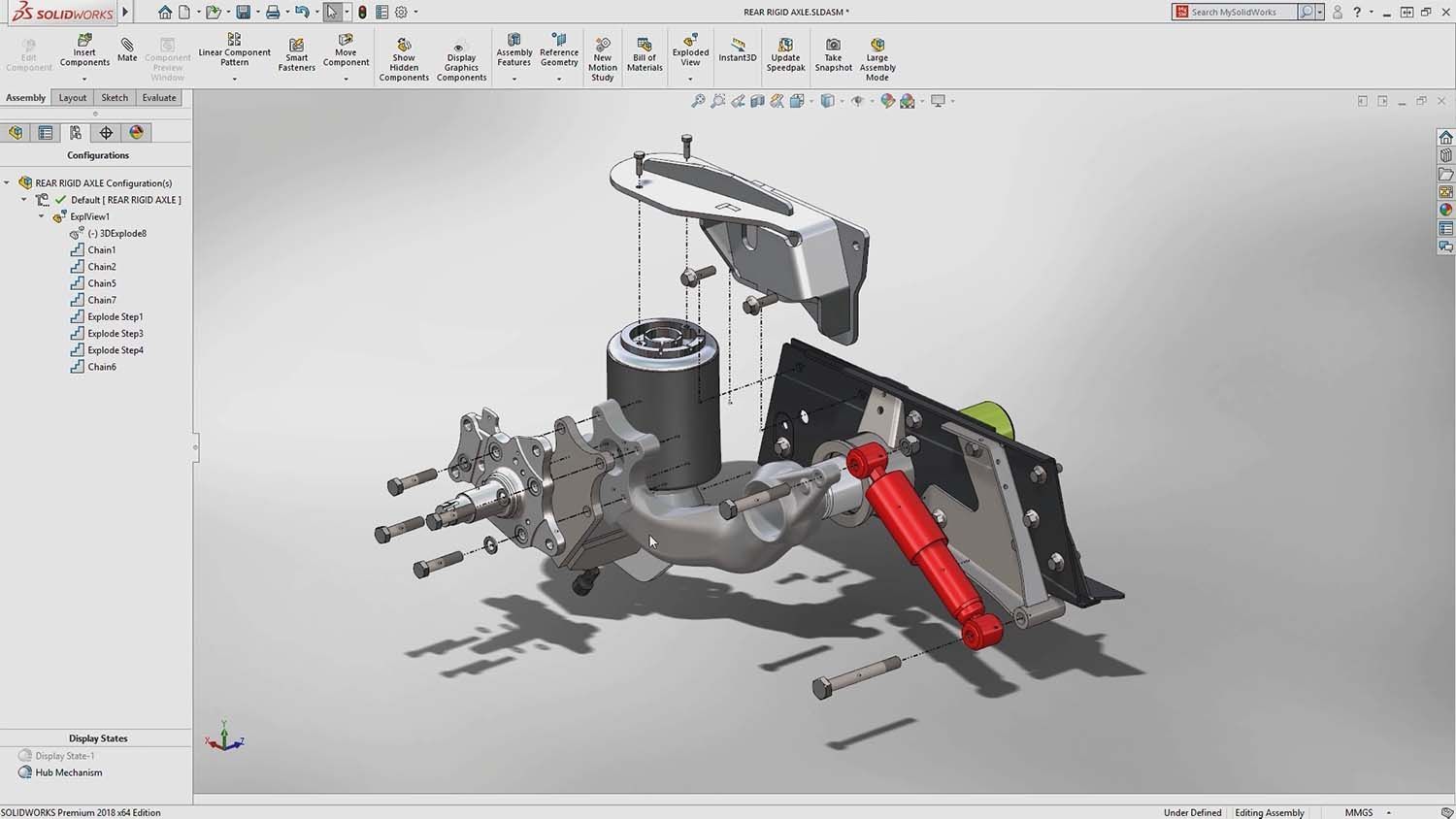

Reverse engineering began in mechanical engineering. Basically, it was necessary here to examine an object so precisely that its function and construction can then be understood in the way that a replica or improvement would be possible. The reasons back then were just as diverse as they are today. Often it is a matter of optimizing products or making repairs possible through new designs.

Quality Management, Production and other areas of application

Quality management has become a very important area of application for reverse engineering today. If a prototype is developed in the course of a manufacturing process, it can be developed back to its original blueprint by remodeling. In this way, the actual construction plan can then be compared with the data that is now available. In this way, production errors and defects can be identified early and the quality of manufactured products can be increased.

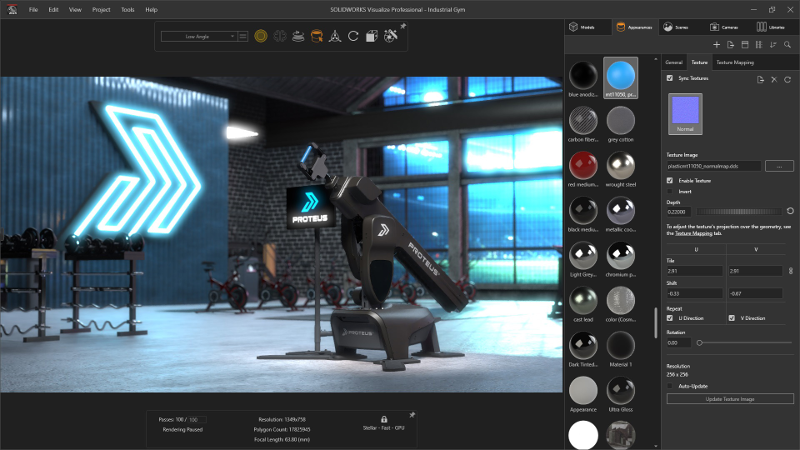

The area of additive manufacturing represents one of the other important areas of application of reverse engineering. With the help of 3D printing, the data obtained through our service can be processed extremely quickly and effectively for further processing. This advantage is of particular benefit to production. Because in this way production costs can be reduced. As a rule, the processing of the data only takes a little time. And desired products can be quickly developed as a prototype, the data of which can then be compared with the original plans.

Benefits of reverse engineering

Mako-Technics’ services offer a wide variety of advantages for a wide variety of industries. The many possibilities for the most diverse areas of application of reverse engineering enable companies to reduce development costs and open up new markets with new developments.

In combination with 3D printing and additive manufacturing, production costs can also be reduced. Our service also enables the analysis of competitive products. In this way, you can improve your own products and set them apart from competitors on the market.

Reverse Engineering by Mako GmbH

The Mako-Technics team has many years of experience in the field of reverse engineering. Our engineers attach great importance to compliance with German quality standards. Do you have any further questions about us or our service? Contact us anytime! We look forward to your inquiry and will be happy to answer it.

If you would like to learn more about areas of application of reverse engineering, us or the industry in general, please use our blog! In this, our team offers you the opportunity to obtain comprehensive information through regular articles and information.

There are no comments