Unlock Precision: Laserscanning Solutions for Reverse Engineering

Unlock Precision: Laser Scanning Solutions for Reverse Engineering

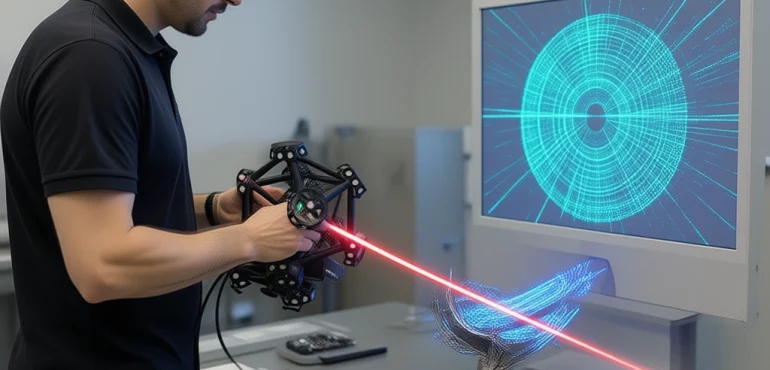

Laser scanning is revolutionizing the field of reverse engineering, offering unparalleled precision and efficiency. As industries increasingly rely on accurate data to recreate complex geometries, laser scanning emerges as a pivotal solution that addresses many challenges faced by engineers and designers.

Understanding Laser Scanning Technology

Laser scanning involves using laser beams to capture precise measurements of an object’s surface. This technology generates a point cloud that represents the physical characteristics of the object in 3D. The ability to collect millions of data points within seconds translates into detailed digital models that can be used for analysis, modification, and reproduction.

The Advantages of Laser Scanning in Reverse Engineering

- High Accuracy: Laser scanning provides exceptional accuracy compared to traditional measurement techniques, ensuring that every detail is captured.

- Speed: The rapid collection of data means projects can move forward quickly, significantly reducing turnaround times.

- Versatility: This technology can be applied to a wide range of materials and shapes, making it suitable for various industries, including aerospace, automotive, and architecture.

- Cost-Effectiveness: By minimizing errors and rework due to precise measurements, laser scanning ultimately saves time and resources.

Applications of Laser Scanning in Reverse Engineering

The applications of laser scanning in reverse engineering are vast. Here are some notable examples:

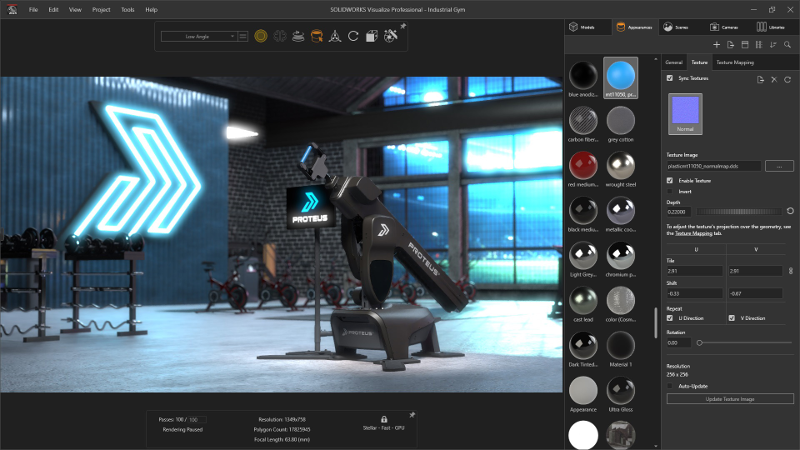

- Product Design: Designers can create accurate digital representations of existing products for modification or improvement.

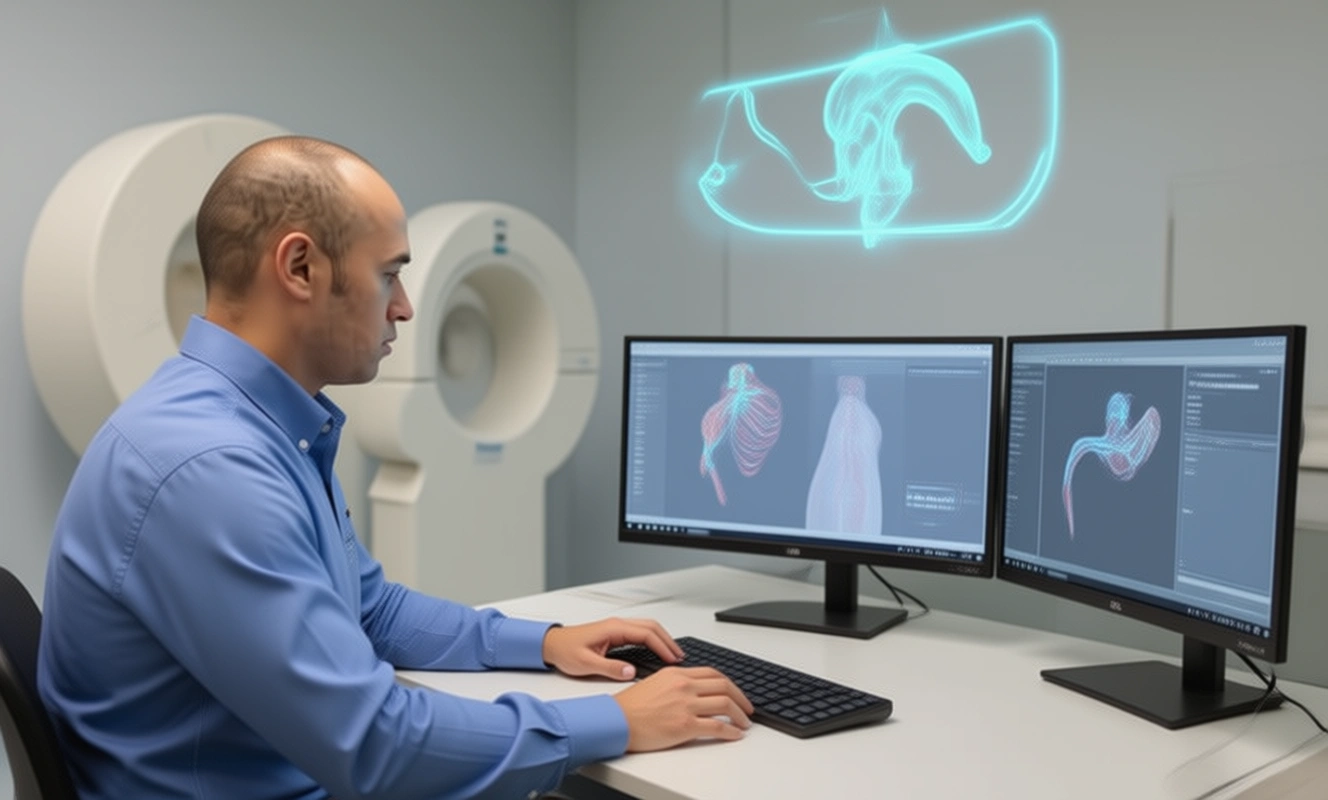

- Cultural Heritage Preservation: Museums utilize laser scanning to document artifacts without causing damage, preserving them digitally for future study.

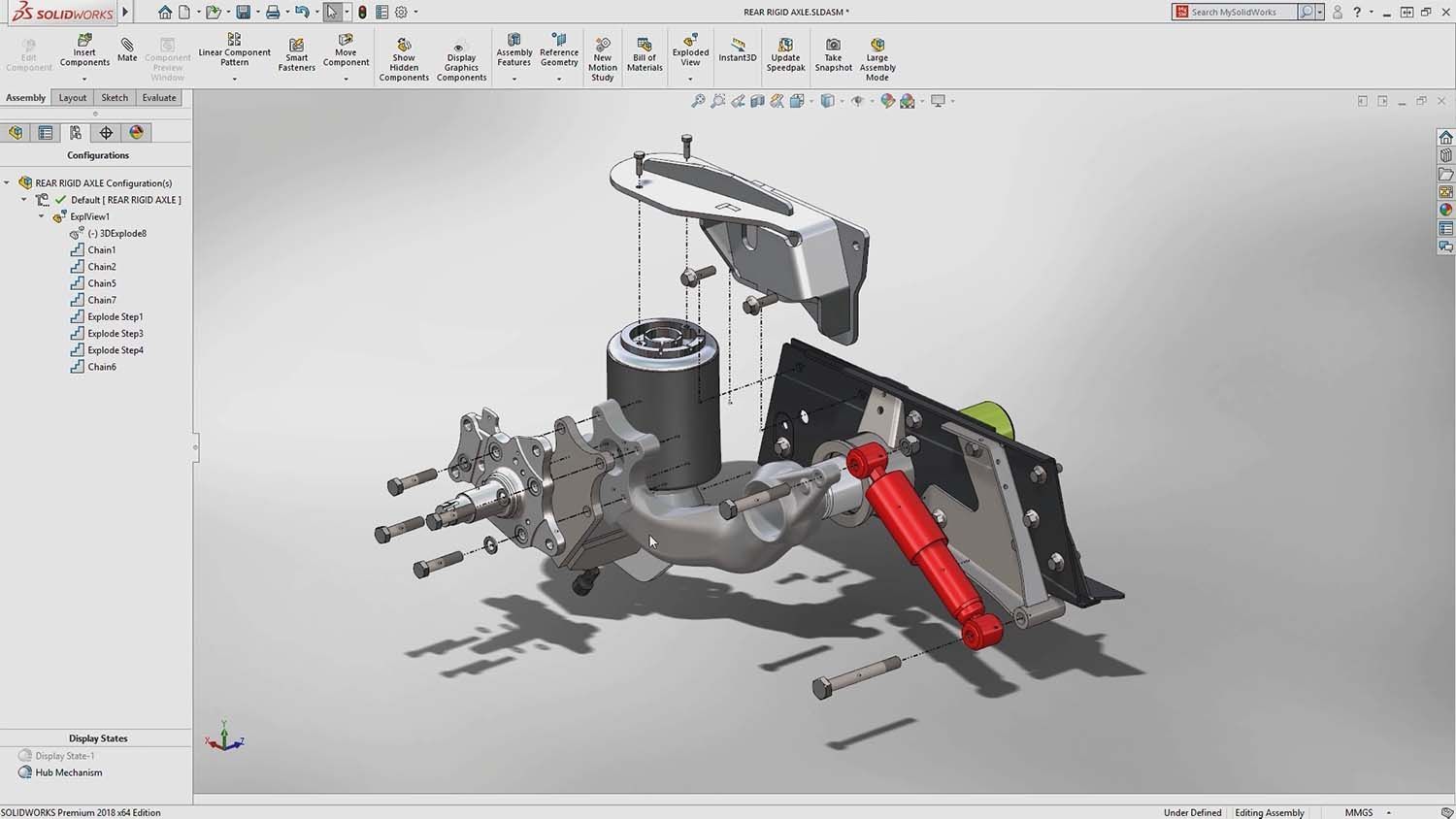

- Aerospace Component Analysis: Engineers can analyze complex components with intricate geometries that require precise replication.

Selecting the Right Laser Scanning Solution

When considering laser scanning solutions for reverse engineering projects, several factors should guide your decision-making process:

- Scanner Type: Different scanners cater to specific needs—handheld models are great for small objects, while stationary scanners excel at larger projects.

- Software Compatibility: Ensure that the scanning solution integrates seamlessly with your existing software tools for data processing and analysis.

- User Experience: Look for user-friendly interfaces that allow quick training and efficient workflow integration.

The Future of Reverse Engineering with Laser Scanning

The future looks promising as advancements in laser scanning technology continue to evolve. Innovations such as improved scanning speeds, enhanced resolution capabilities, and advanced software algorithms will further streamline reverse engineering processes. As industries embrace these technologies, organizations will find themselves better equipped to tackle design challenges and meet market demands efficiently.

Your Pathway to Enhanced Precision

If you’re ready to elevate your reverse engineering projects through cutting-edge laser scanning solutions, explore the options available today. Invest in technology that not only enhances accuracy but also boosts productivity across your team. With laser scanning at your disposal, transforming concepts into reality has never been easier or more effective.

How can we help you?

Do you have further questions about us or reverse engineering? Contact us anytime! We are looking forward to your message.

Would you like to learn more about exciting reverse engineering topics? Please visit us on YouTube! There we regularly provide videos on exciting topics.

There are no comments