Comparison of the Real World with the CAD World

Comparison of the Real World with the CAD World

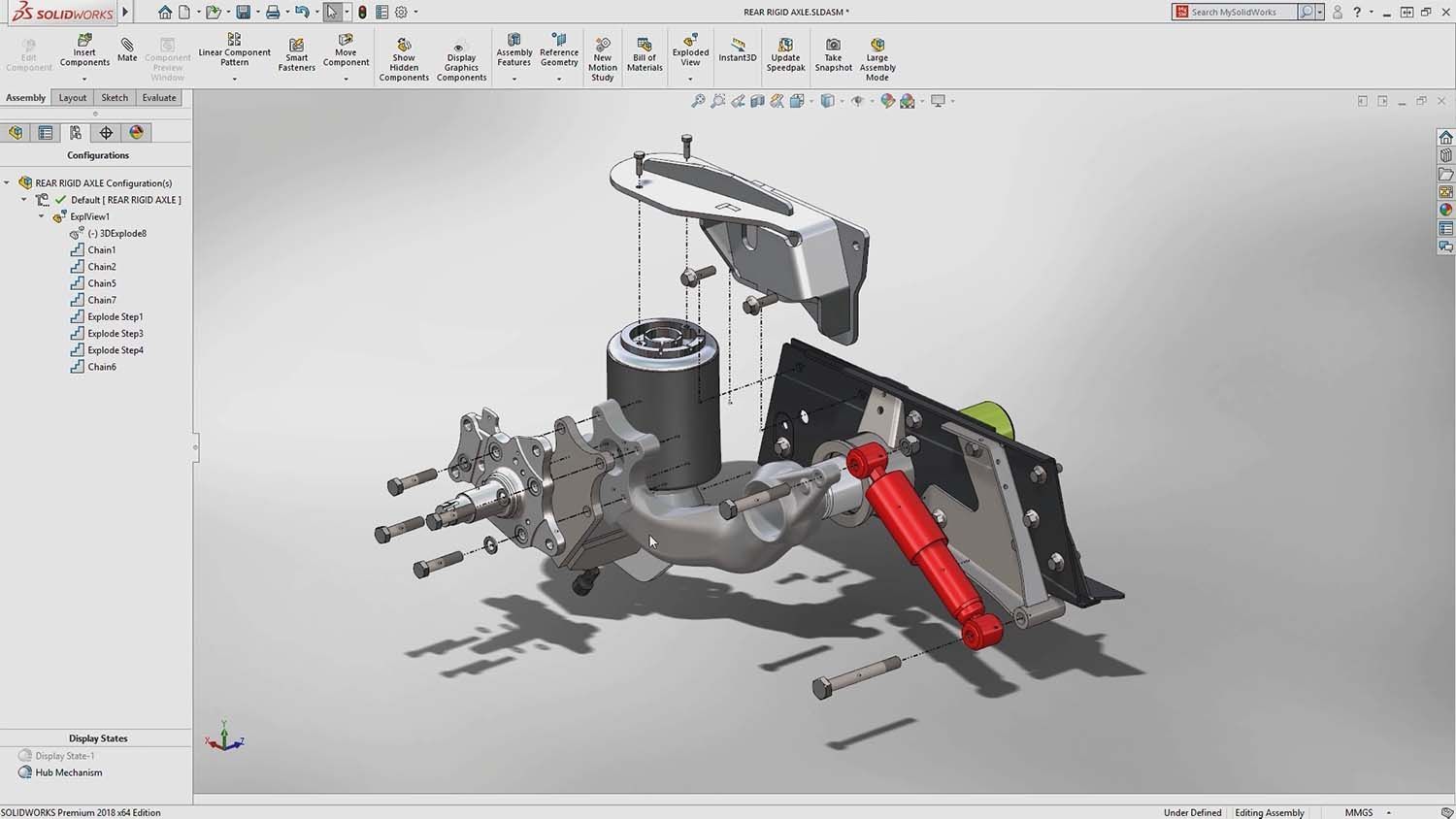

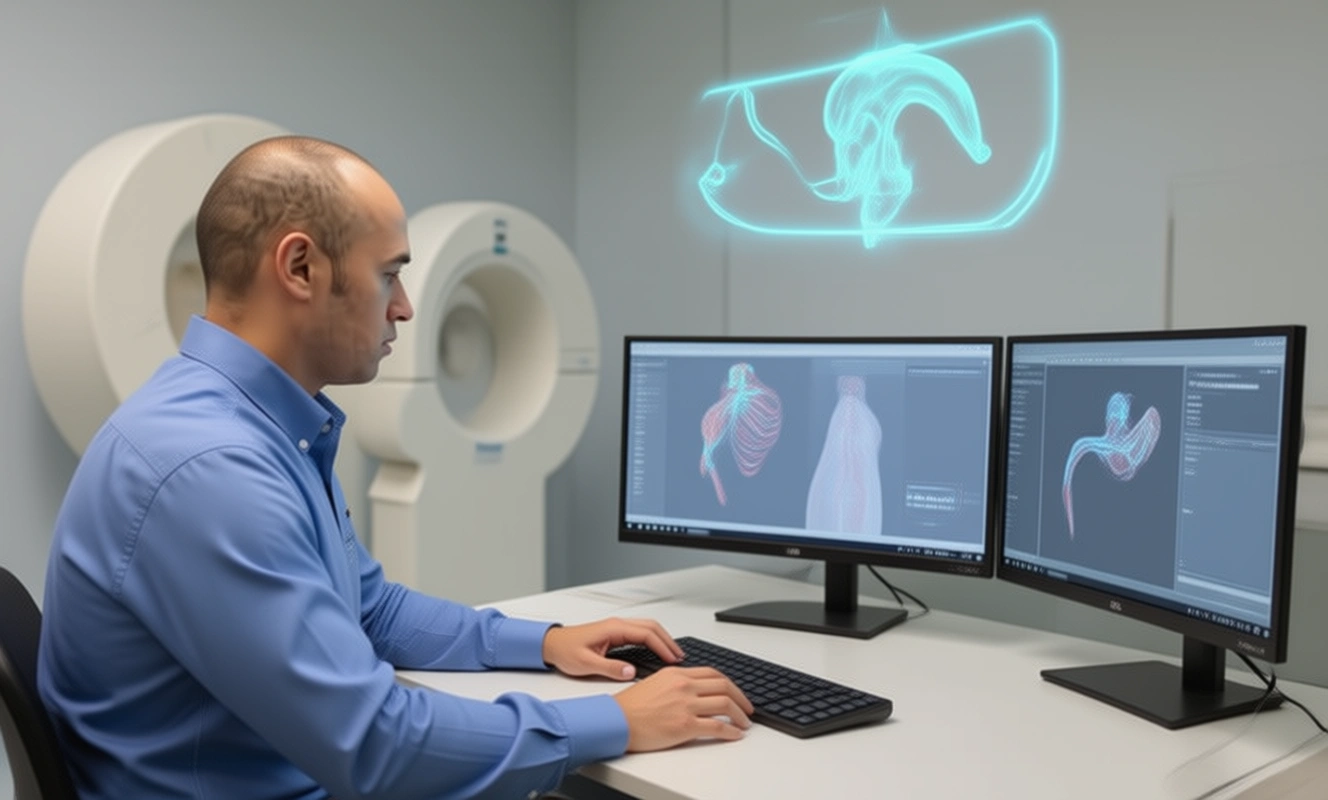

Reverse engineering enables the creation of CAD surface models. These volume models represent previously scanned objects or parts very precisely. We never tire of emphasizing that the areas of application of reverse engineering are almost unlimited. RE is used in a wide variety of industries and areas – in areas where work is carried out on real existing objects and at the same time precise CAD models are required for the further process. The reverse engineering process basically describes a comparison

the comparison of the real world with the CAD world. Are you interested in this? The experts at Mako-Technics will be happy to introduce you to this topic in more detail.

Do you need help quickly from reverse engineering experts? Contact the engineers at Mako GmbH directly here.

RE compares CAD with the real world

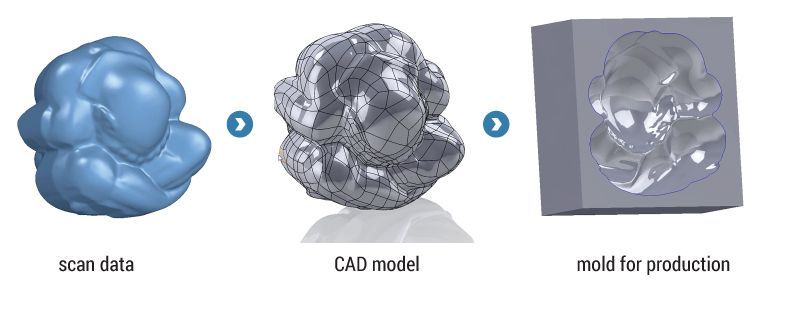

Our services are successfully used, for example, in mold and model making. In this application area, we first scan a modeled object. We then convert the resulting point cloud into a CAD volume model.

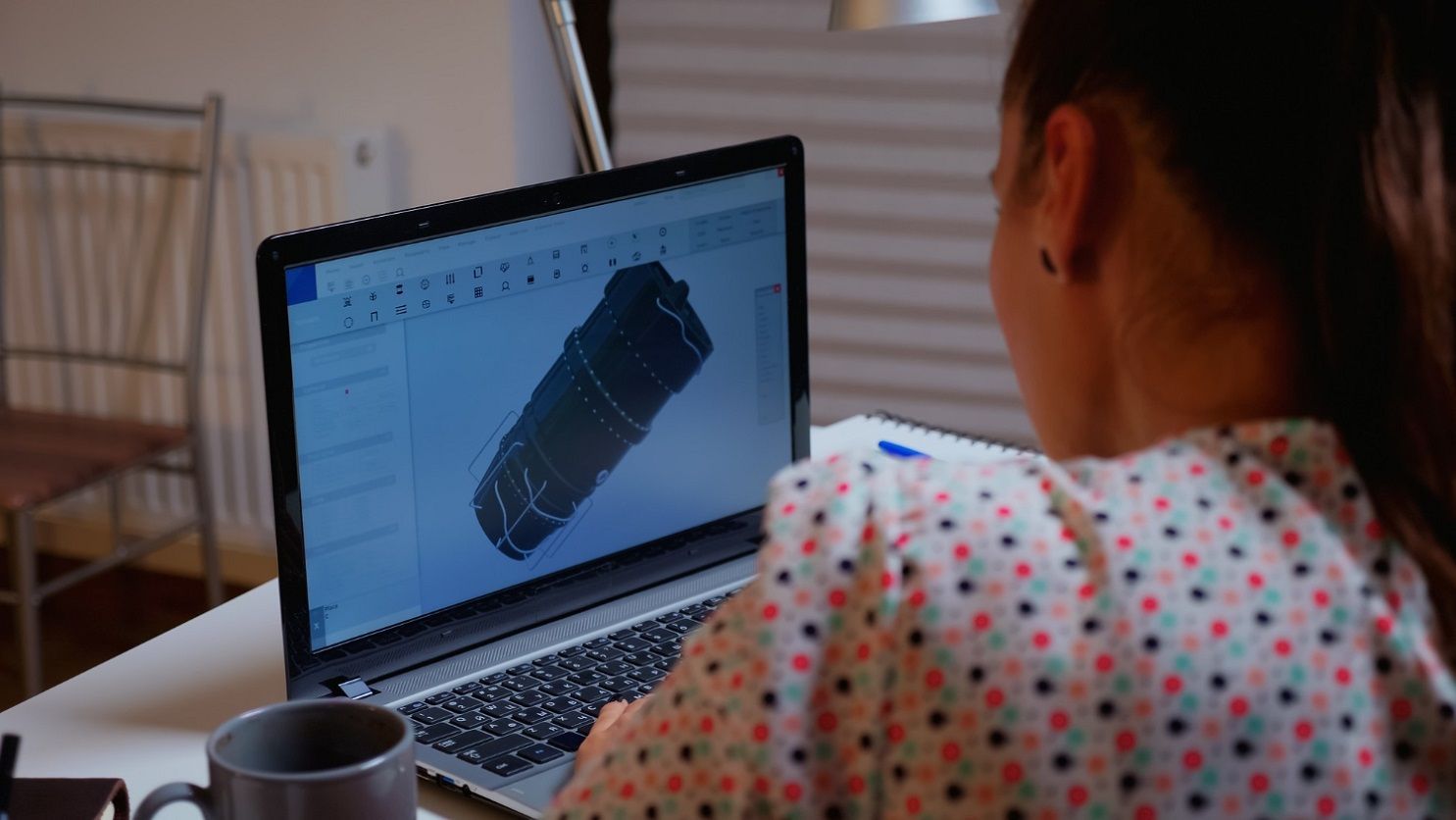

Another area of application for reverse engineering is tool optimization. In this case, components (tools or their individual parts) are recorded by us with a scanner. We then optimize the resulting point cloud in detail, i.e. we check deviations such as warpage. Once we have put the finishing touches to the point cloud, we also convert the data of this polygon mesh into a CAD volume model.

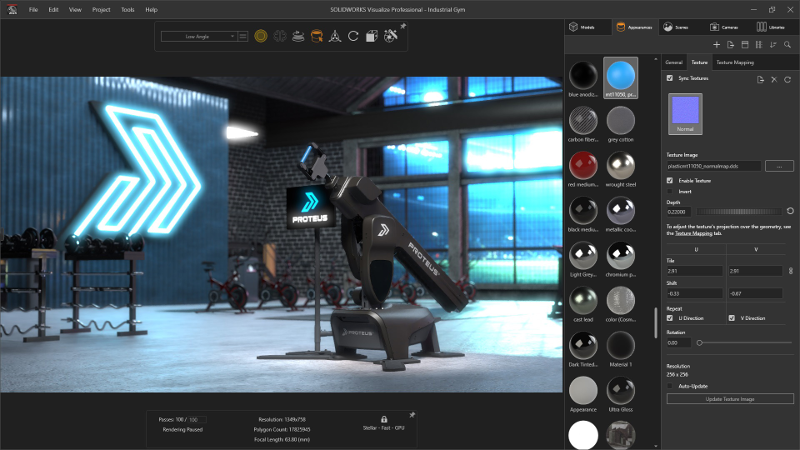

You see one more time: Reverse engineering offers many advantages in an enormous number of industries and areas. One thing is particularly important to us. We would like to give you the opportunity to understand our service also figuratively. On the one hand, RE gives you the opportunity to digitally display physical objects. On the other hand, with our help you can compare your real existing component with its CAD model with each other with high precision.

How does Mako-Technics help with the comparison between CAD and real component?

If you are wondering how exactly our service works, we can put you at ease. In the following we will give you an insight into our procedure. Our individual work steps are as follows:

- First we read in the STL data

- We then analyze the network data and optimize it if necessary

- Now we draw a wire model on this network data

- Here we create individual surfaces

- We then analyze them and optimize them

- After we have made your 3D CAD model available to you, you can use it for further processing, adjustments or corrections

The Mako-Technics team

The Mako GmbH team based in Germany has decades of experience in reverse engineering. Do you have further questions on this topic or do you need the help of experts? Get in touch with us at any time! We look forward to your inquiry.

Are you interested in other topics related to the industry? Then take a look at our blog! There you can find out more about many topics.

There are no comments