Benefits of Reverse Engineering

What are the Benefits of Reverse Engineering?

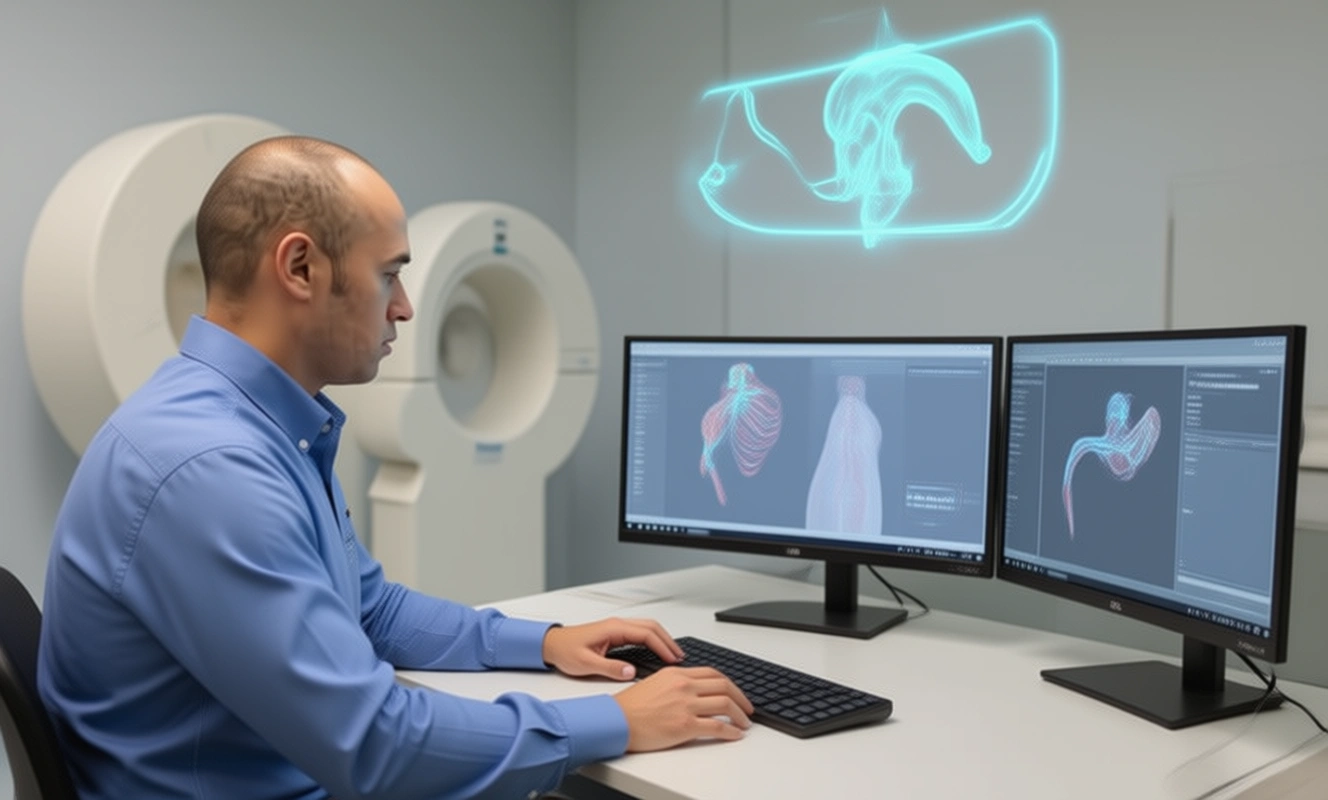

In this Blog article, Reverse Engineering Service experts Mako GmbH explain the benefits of using Reverse Engineering (RE). RE is basically the process of analyzing a real-world object or environment to collect data on its shape and possibly its appearance.

Benefits of Reverse Engineering

Engineering is a very versatile industry that is always getting creative. Using creativity and innovation, engineers create never-before-seen products that benefit their communities. They play a key role in expanding local economy and sparking business exchanges. However, one question remains: how do engineers innovate in such a fast-paced environment?

The answer is the reverse, literally. RE plays a huge role in sparking innovative and productive minds that produce necessities across every industry. The RE process includes taking a part worn down products to examine how individual parts work, and then incorporating past inventions into new ones. There are plenty of benefits to the reverse engineering process that will only expand our knowledge and capabilities.

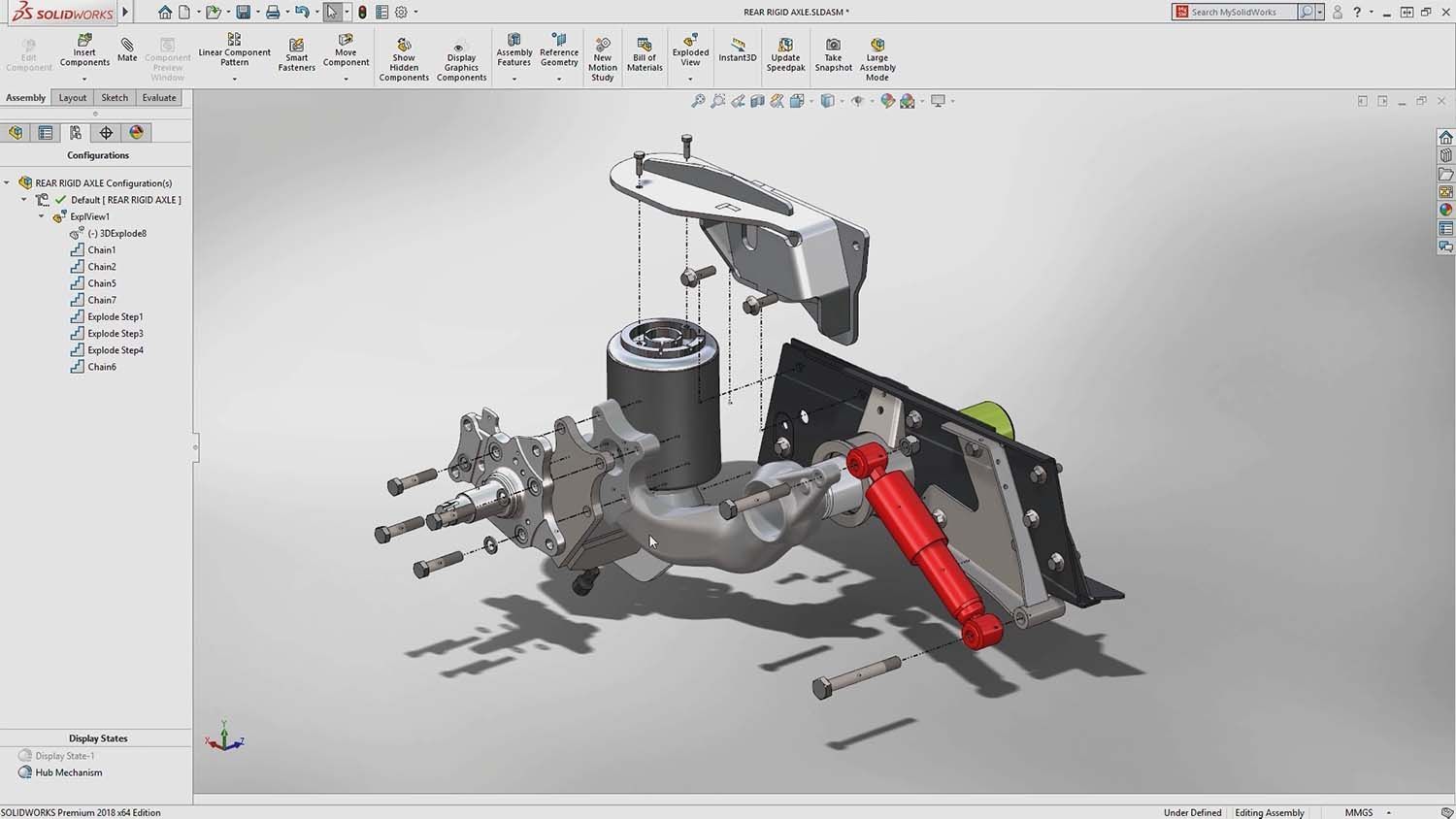

Exploring existing designs and maneuvers

RE allows us to see what already exists. This includes any parts, structures, or processes that could benefit communities in other ways. Examining current products leads to innovation and discovery, all thanks to reverse engineering.

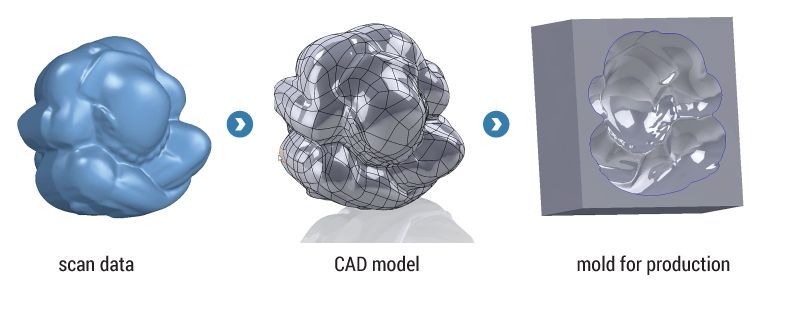

Reconstructing a product that is outdated

A key part of redesigning an existing product is understanding the product itself. RE provides the visual to work out outdated kinks in an older system. Quality is the most important aspect of this process.

Discovering any product vulnerabilities

Similar to the previous step, reverse engineering supports finding faults in the product. This is to ensure the safety and well-being of the product’s users. It is best for an issue to arise during the research phase rather than the distribution phase.

Bringing less expensive & more efficient products to the market

Reverse engineering’s main goal is to lead engineers on a path towards innovation and success. Succeeding includes lowering manufacturing costs and raising product effectiveness as much as possible.

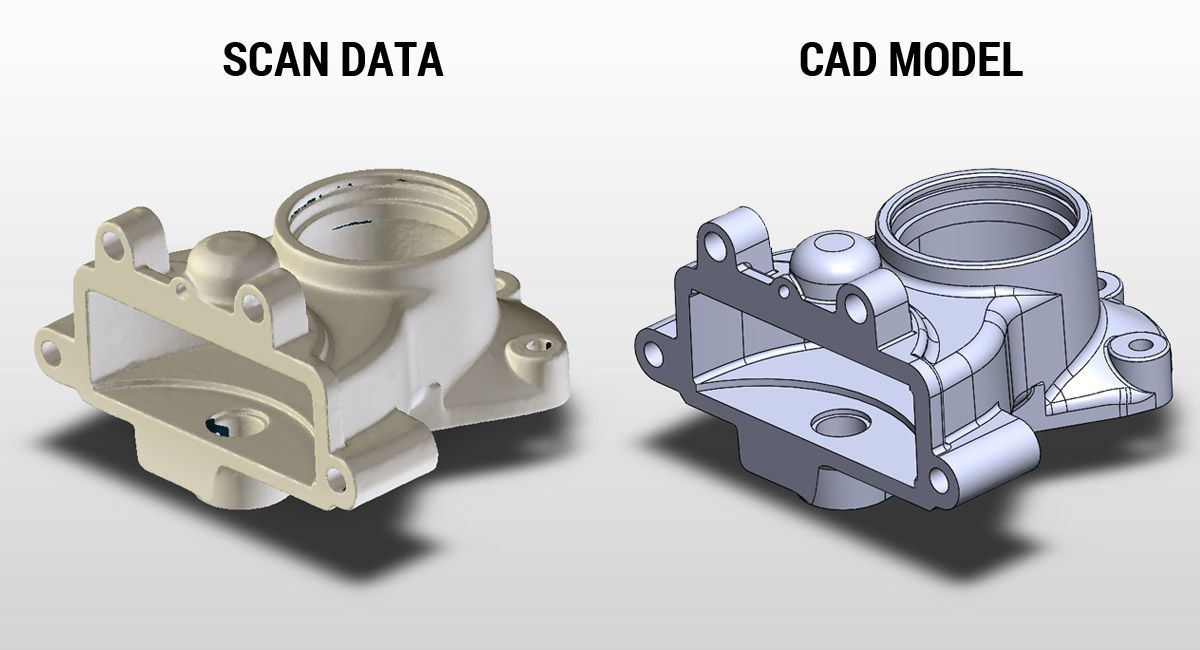

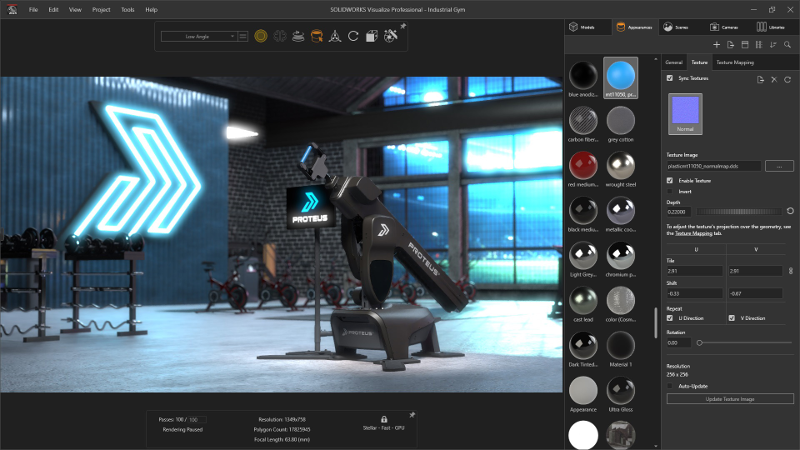

Creating a reliable CAD model for future reference

Most RE processes include a full-working CAD file for future references. A CAD file is created so the part can be examined digitally if future issues arise. This form of technology has enhanced engineering productivity and product expression.

Inspiring creative minds with old ideas

Lastly, RE gives way for innovative design. During the process, an engineer might discover a system that could be useful for a completely different project. This shows how engineering connects projects with previous knowledge.

If you want to learn more about Reverse Engineering, CAD software and how to master them check out our Blog Posts here or contact us here to get in touch with a Reverse Engineering expert!

There are no comments