Top Benefits of 3D Inspection Scanners for Quality Control

Top Benefits of 3D Inspection Scanners for Quality Control

Quality control is an essential aspect of manufacturing and product development, ensuring that every item meets the required specifications. As industries evolve, traditional methods of inspection are increasingly being supplemented or replaced by advanced technologies. One such innovation is the 3D inspection scanner, a powerful tool that enhances quality control processes with remarkable precision and efficiency.

Understanding 3D Scanning for Quality Control

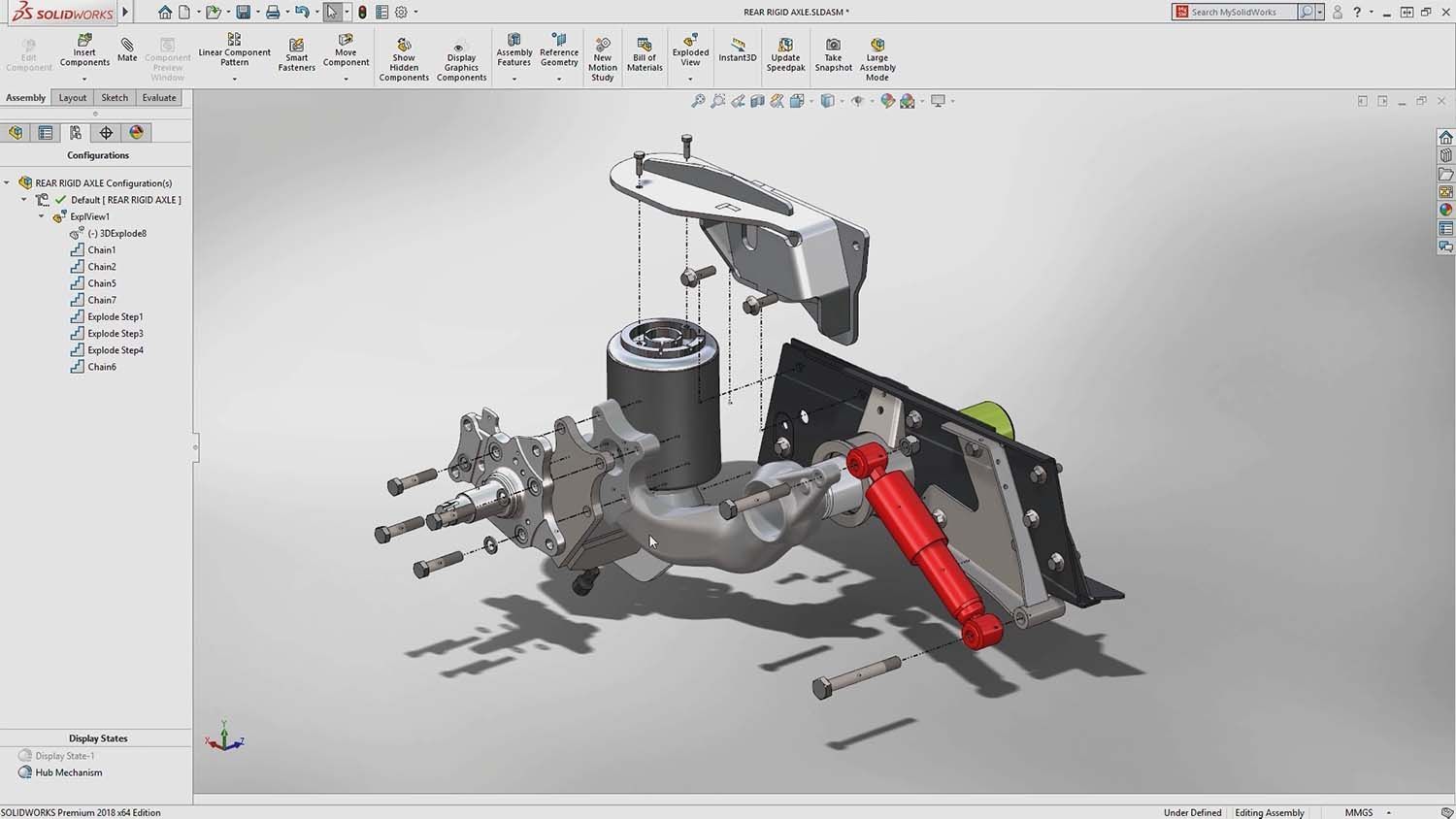

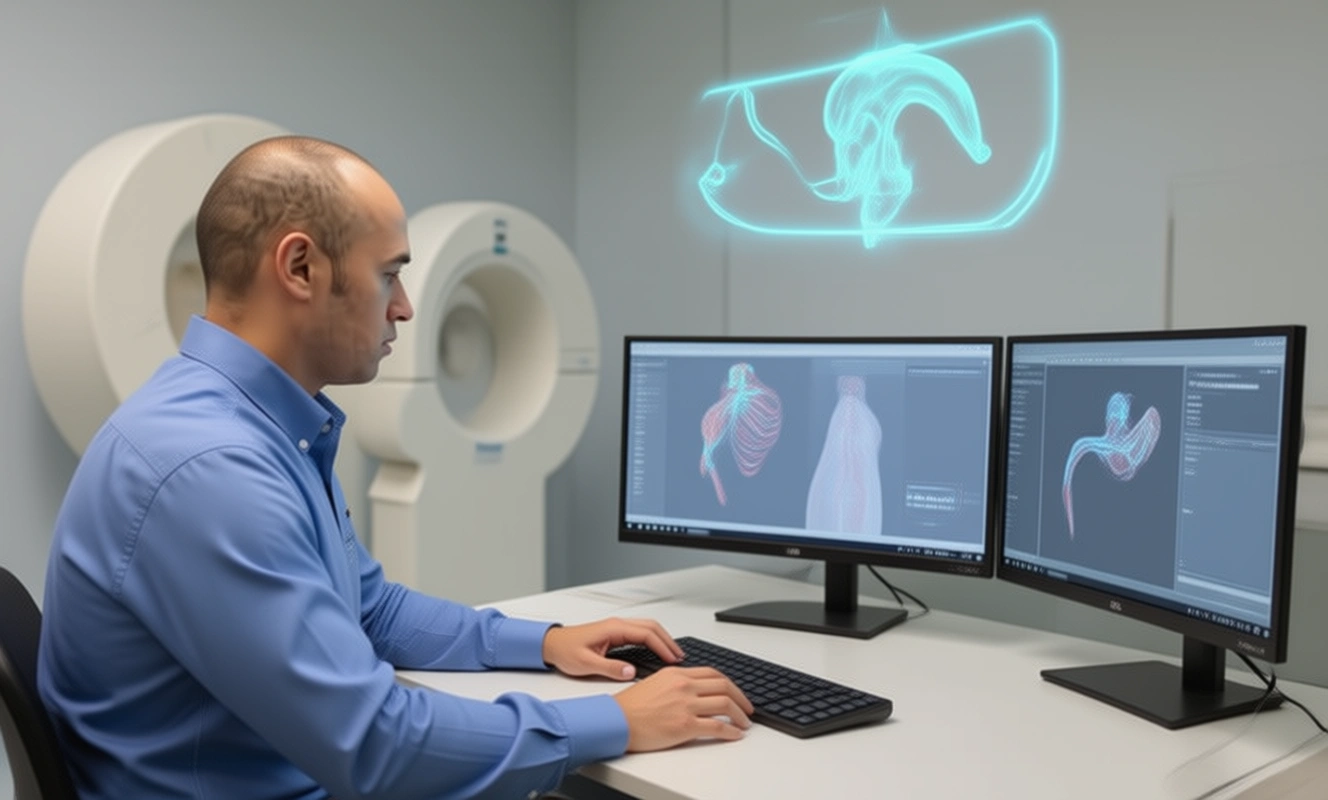

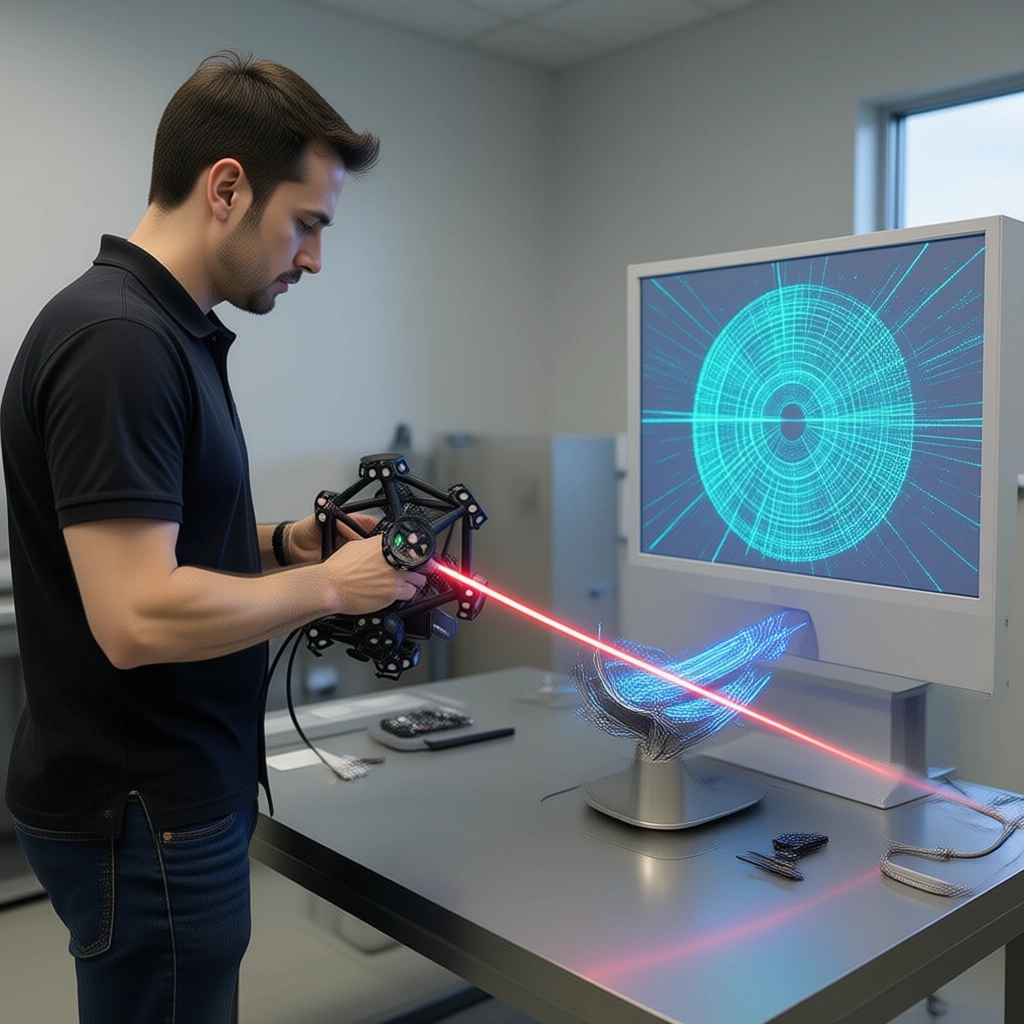

3D scanning quality control involves capturing the physical characteristics of an object through digital representations. This technology allows manufacturers to create accurate models that can be analyzed for discrepancies against design specifications. With the ability to quickly gather data, businesses can identify defects early in the production process, reducing waste and saving costs.

Key Advantages of Using 3D Inspection Scanners

- Precision and Accuracy: 3D scanners provide detailed measurements down to microns, ensuring that every facet of a product is scrutinized. This level of detail is especially beneficial in sectors like aerospace and automotive, where even minor deviations can lead to significant issues.

- Speed: Traditional inspection methods can be time-consuming. In contrast, 3D scanning inspection can capture thousands of points in seconds, enabling rapid assessments and faster turnaround times.

- Versatility: Whether it’s a small component or a large assembly, laser scan inspection is adaptable to various sizes and shapes. This flexibility makes it suitable for diverse applications across different industries.

- Error Reduction: Manual inspections are prone to human error. Automated quality control 3D scanning minimizes these risks by providing consistent results, enhancing reliability in quality assurance processes.

- Easier Data Management: The digital nature of 3D scans allows for easy storage, retrieval, and analysis of data compared to physical records. This enables better tracking of quality trends over time.

The Role of 3D Scanning in Quality Inspection Processes

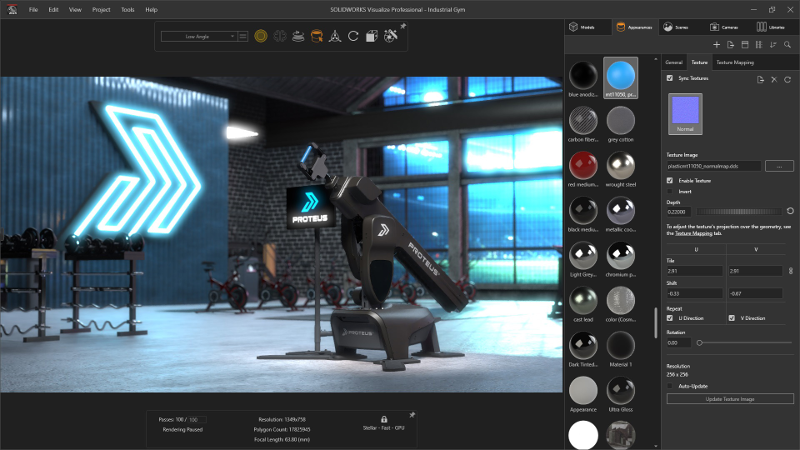

The integration of 3D scanner quality inspection into quality control workflows streamlines operations significantly. By utilizing structured light scanning or laser scanning techniques, companies can achieve real-time feedback on production quality. This immediate insight allows teams to make informed decisions quickly, addressing any flaws before they escalate into larger problems.

Certain Applications Where 3D Scanning Shines

What can 3D scanners be used for? Here are several applications where their capabilities excel:

- Aerospace Components: Ensuring compliance with stringent safety standards by validating complex geometries.

- Mold Making: Verifying mold integrity and precision before fabrication begins.

- Cultural Heritage Preservation: Documenting artifacts with high fidelity for restoration projects.

- Piping Systems: Checking alignment and fit within complex installations in industrial settings.

The Cost Factor: Are 3D Scanners Worth It?

How much do 3D scanners cost?

The initial investment in a high-quality 3D scanner may seem daunting; however, the long-term benefits often outweigh the costs. By reducing material waste and minimizing rework due to errors, businesses see improved profitability over time. Additionally, many companies find that the efficiency gains from using a 3D scanner far surpass the expenses associated with acquiring one.

Your Next Steps Towards Enhanced Quality Control

Investing in a 3D scanner for quality control not only bolsters your QA processes but also positions your business as an industry leader embracing cutting-edge technology. As you consider making this transition, weigh your specific needs against the vast capabilities offered by different models on the market today.

By leveraging advanced tools like laser scanners or automated scanning inspection systems, you unlock potential improvements in product quality and operational efficiency that benefit both your bottom line and customer satisfaction.

The Future Awaits: Transform Your Quality Control Practices Today!

Embrace the future of manufacturing with innovative solutions like quality control 3D scanning. By adopting this technology now, you position your organization at the forefront of industry advancements—ensuring superior products that consistently meet customer expectations.

How Can We Help You?

Do you have further questions about us or reverse engineering? Contact us anytime! We look forward to your message.

Would you like to learn more about exciting reverse engineering topics? Please visit us on YouTube! There, we regularly provide videos on exciting topics.

Interested in Augmented Reality (AR) solutions? Learn more about our AR services on ar-4u.com

There are no comments