Unlocking Reverse Engineering with 3D Scanning Technology

Unlocking Reverse Engineering with 3D Scanning Technology

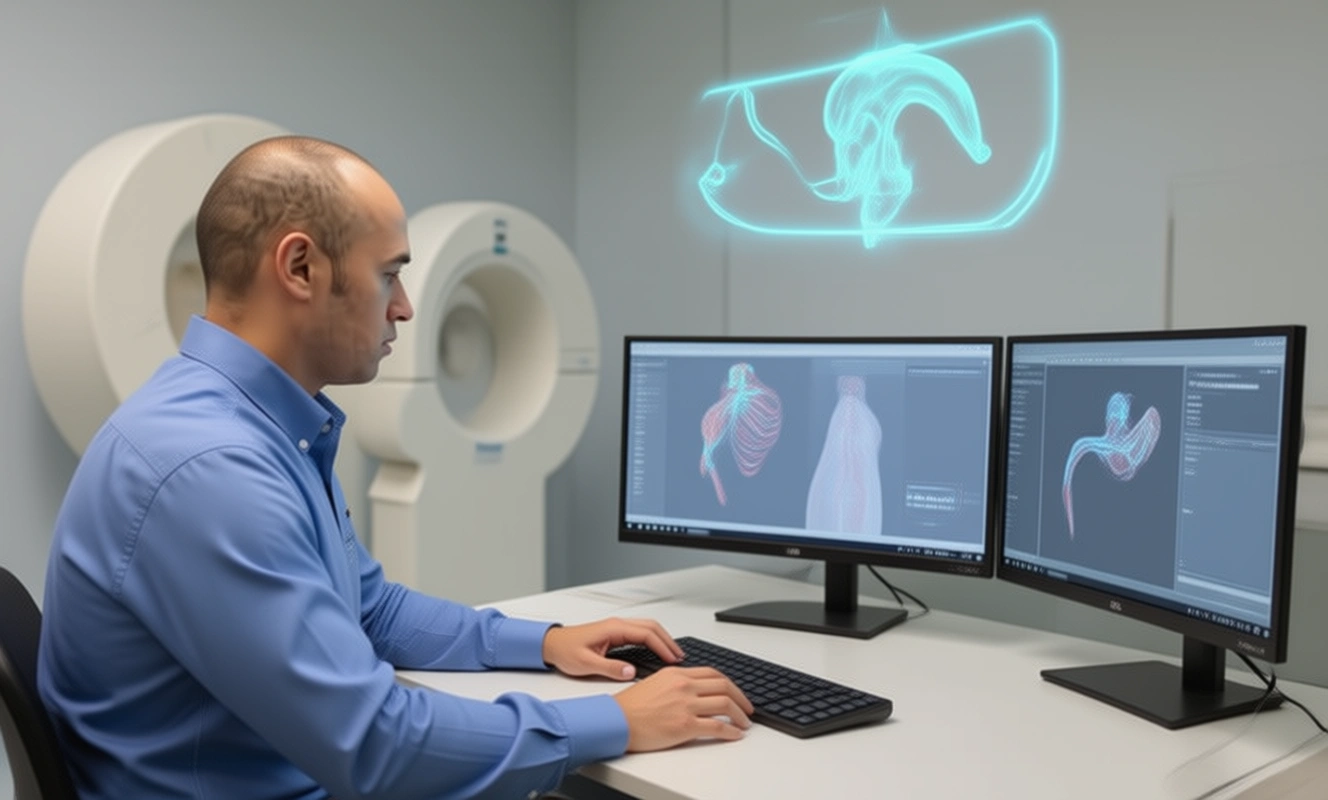

3D scanning technology is revolutionizing the field of reverse engineering, offering unparalleled accuracy and efficiency. By converting physical objects into digital models, this innovative approach simplifies complex processes in design and manufacturing. Let’s explore how 3D scanning can enhance your reverse engineering projects.

Understanding 3D Scanning Technology

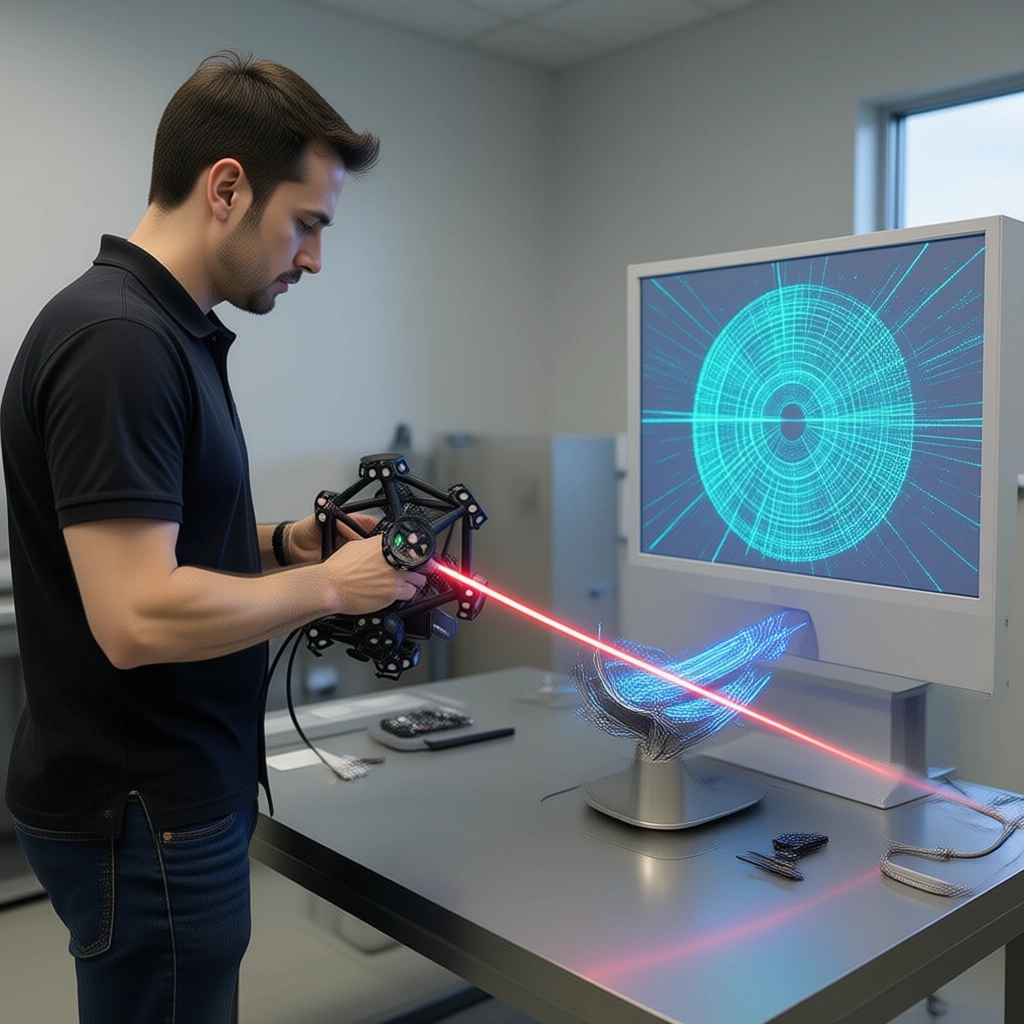

At its core, 3D scanning involves capturing the exact shape of a physical object and creating a digital representation, often referred to as a point cloud. This process allows engineers and designers to analyze intricate details that would be challenging to replicate manually. But how does it work?

- Data Collection: A 3D scanner emits laser beams or light patterns onto the object, measuring distances to create a precise map of its surface.

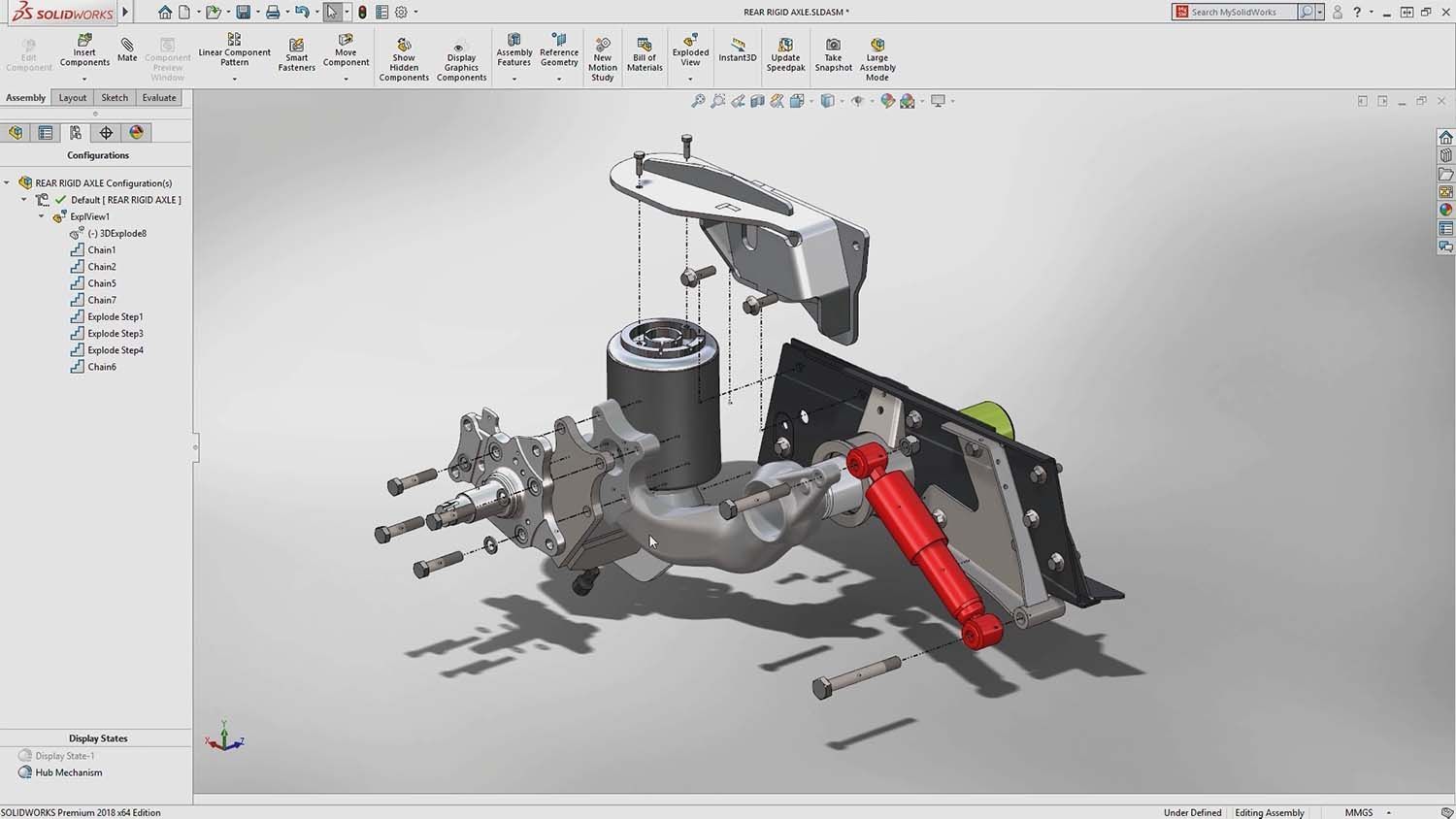

- Point Cloud Generation: The collected data points form a detailed 3D reconstruction, representing the object’s geometry.

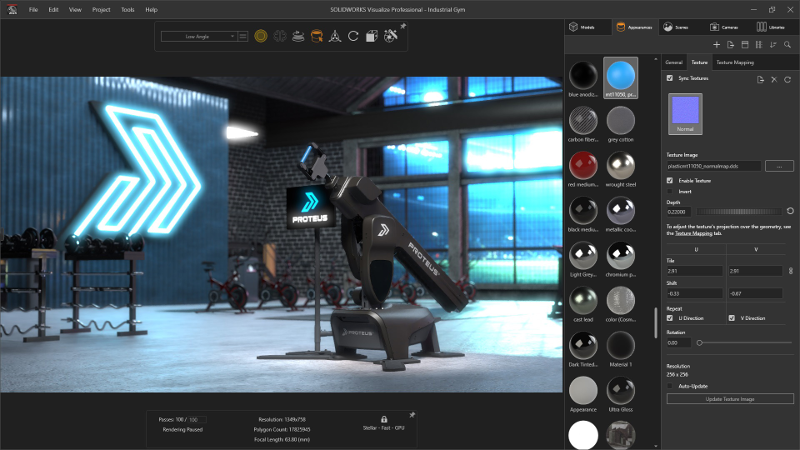

- Model Creation: Using CAD software, the point cloud is transformed into a usable 3D model for further analysis or modification.

The Benefits of 3D Scanning in Reverse Engineering

The integration of CAD scanning with 3D scanning technology brings numerous benefits to reverse engineering endeavors:

- Enhanced Accuracy: Achieve high precision in measurements, reducing errors during the modeling process.

- Time Efficiency: Expedite the digitization process significantly compared to traditional methods.

- Easier Modifications: Quickly adjust designs based on accurate data without starting from scratch.

- Simplified Collaboration: Share digital models easily among team members for improved collaboration and feedback.

Applications of 3D Scanning in Reverse Engineering

The versatility of 3D scanning technology makes it suitable for various applications across different industries:

- Aerospace and Automotive: Analyze components for repairs or upgrades with precise measurements.

- Cultural Heritage: Preserve artifacts by creating detailed replicas without risking damage.

- Manufacturing: Streamline production processes by optimizing existing designs based on accurate scans.

Selecting the Right 3D Scanner for Your Needs

When considering adopting 3D scanning technology for reverse engineering projects, it’s crucial to choose a scanner that fits your specific requirements. Factors to consider include:

- Accuracy Level: Determine the precision needed for your application.

- Diverse Material Compatibility: Ensure the scanner works well with various materials you plan to scan.

- User-Friendliness: Look for scanners that offer straightforward operation and software integration.

The Future of Reverse Engineering with 3D Technologies

The future is bright for reverse engineering as advancements in 3D scanning technologies continue to emerge. Innovations such as enhanced algorithms for processing point clouds and improved integration with AI are on the horizon, promising even greater efficiencies and capabilities. As more industries recognize these advantages, embracing these tools becomes essential for staying competitive.

Your Next Steps in Embracing 3D Scanning Technology

If you’re ready to elevate your reverse engineering projects through cutting-edge technology, exploring the various options available on the market is essential. Investing in a quality 3D scanner, whether it’s handheld or stationary, can significantly enhance your workflow and output quality. With accurate data at your fingertips, you can transform ideas into reality faster than ever before!

How Can We Help You?

Do you have further questions about us or reverse engineering? Contact us anytime! We look forward to your message.

Would you like to learn more about exciting reverse engineering topics? Please visit us on YouTube! There, we regularly provide videos on exciting topics.

Interested in Augmented Reality (AR) solutions? Learn more about our AR services on ar-4u.com.

There are no comments