PIONEERS IN REVERSE ENGINEERING AND CAD WORKS

REVERSE ENGINEERING

SERVICES OF MAKO GMBH, GERMANY

Scan to CAD or pointcloud to CAD

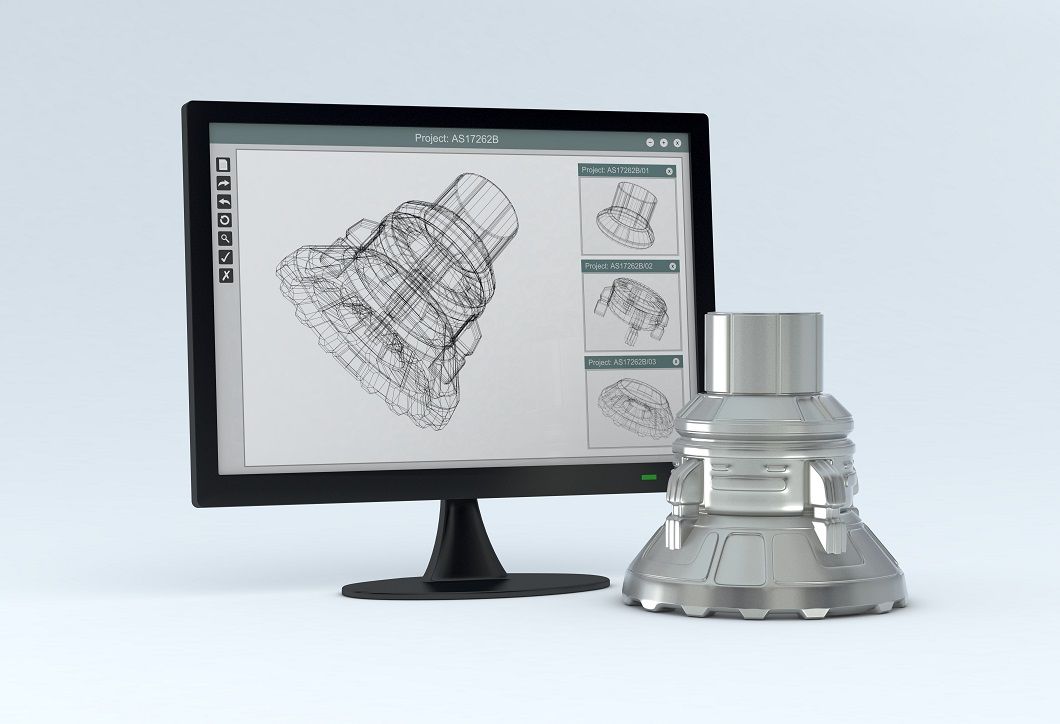

OUR company specializes in Reverse Engineering of 3D scans and pointcloud data into well-structured CAD files.

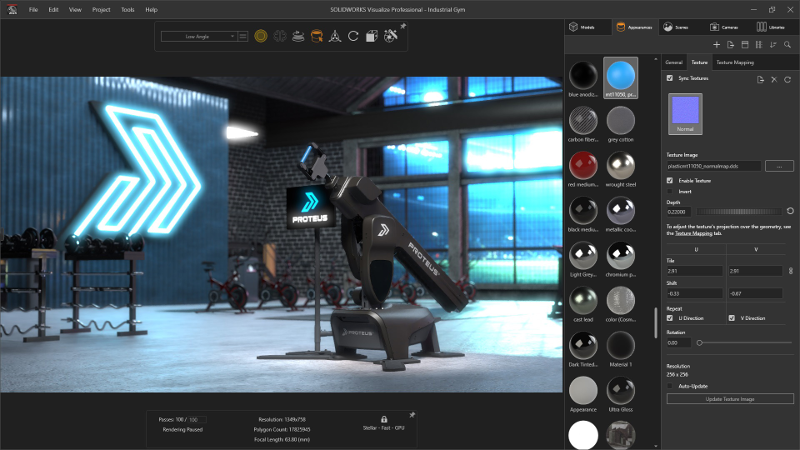

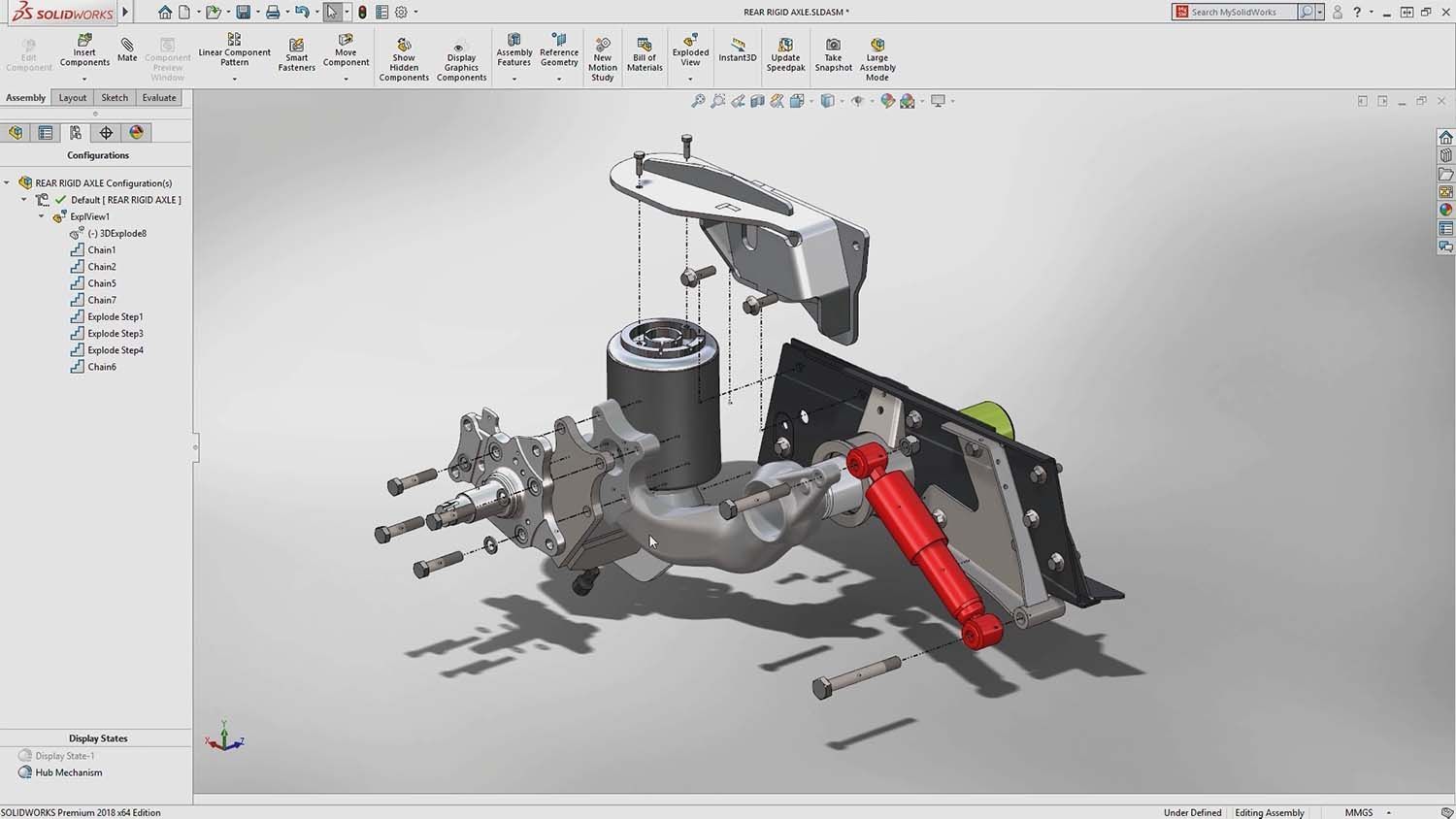

We use the following CAD Software:

- Catia V6: used for modelling products in their daily real-life content

- Creo: perfect for remodeling old parts that have incurred damaged or have missing areas

- Solidworks: great for 2D and 3D designs as well as ECAD and MCAD integration

- DesignX (Geomagic): this is one software that does everything, from recreating CAD for lost or damaged parts, to designing custom products

- Siemens NX: Streamlines the product development process, from design and simulation to engineering and manufacturing

- Auto Desk Inventor: provides a great blend of freeform, direct editing capabilities, and parametric tools

We will provide you with the native CAD files regardless of the software you choose. The ready CAD data will finally represent the outside volume structure of your item.

Simulations and molding Software we use:

Cadmould utilizes the 3D-F methodology for simulations, to deliver fast and precise results when handling injection moulding projects. The high-precision simulation results for Cadmould facilitate decision-making in the development of complex plastic parts. This ensures that all the decisive criteria can be configured in an optimal manner.

Ansys eliminates the need for conducting expensive test runs on products by simulating different attributes of a model, such as strength, fluid flow, elasticity, electromagnetism, etcetera, on a computer model. The resulting product tends to be lower in weight and consumes less material to build.

We use GomInspect Pro to check produced parts, to ensure tolerances match with the requirements of CAD data. This is widely used for quality checks during professional production processes. We especially use this software for initial sample check. GOM Inspect Suite allows for a standardized ISO visualization.

Which 3D scanner is best suited for your project?

For 3D scanning of your items, we recommend state of the art 3d scan device from Shining3D Creaform, Solutionix or GOM.

• High scanning speeds: (Handheld HD Scan) 20fps 1,100,000 points / s and (Handheld Rapid Scan)30fps1,500, 000points/s

• 100 data acquisition lines

• Enlarged scan area 312X204mm

• works up to an accuracy of 0.05mm

• Uses white light pattern

• highly efficient in capturing 3D models of medium to large objects

• Easily expanded with computer-controlled turntable or a color camera.

• It catches fine details, so it’s good for scanning geometrically complex objects

• Scans with precision and speed

• Dual cameras to deliver high resolution scans

• Automatic scanning of whole objects with one click

• Active synchronization of model and camera views, allowing you to easily see the scanning positions and go for a rescan where needed.

• Automatic calibration that is convenient and lets you scan an object with a single click

• 3-axis turntable (TA300+) to facilitate scanning beyond limits

• Install on a tripod to scan larger objects

• No manual registration or targeting needed

• (Desktop HD Scan) 20fps 1,100,000 points / s

• Dynamic referencing, for high resolution images even with movement

• Can capture fine details

• High accuracy 0.025 mm (0.0009 in)

• Measurement rate of 1,300,000/s

• Can scan a large area (11 laser crosses)

• Lightweight, portable and requires no tripod or other devices to operate

• Easily detects shiny surfaces, fine edges and fissures

• It’s great for inspection analysis

• It can measure and inspect objects of different sizes, from small to extra large

• Triple Scan functionality allows for scans in any type of lighting, faster, accurately and with less scan requirements

• The scanner is photogrammetrically expanded, allowing it to capture multiple components at the same time.

Our Partner:

We work with partners from all over the world, to provide ready 3D scanning support at their scanning facilities or on site at your premises.

Our partners use a wide array of scanning machines such as: Shining3D, GOM, CREAFORM, Solutionix, Artec, Keyence, Leica, Faro and plenty more…

If you aren’t sure of the best scanner for your object, CONTACT US and we will help you take your pick.

Our process:

Every step of reverse engineering process begins with choosing the right CAD software to suit your specifications. The Mako-Technics team then uses the software of your choice to rebuild your source file into high quality CAD data.

We dedicate a team of highly qualified, experienced and dedicated engineers to take on your project.

The project team decides the details of the reverse engineering process and agree on the quickest and most precise way of remodeling.

Accurate reverse engineering work done by hand

Reverse engineering is done by hand. Before starting to rebuild pointcloud data, structures, geometries and functionalities have to be considered.

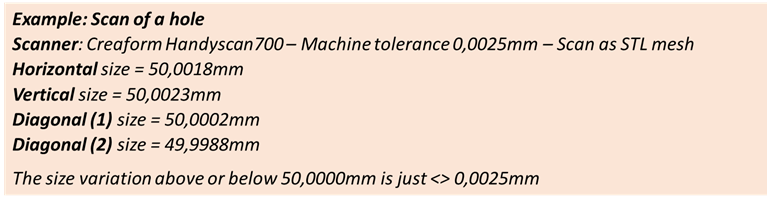

3D Scanners scan quickly and precisely, but no matter how good they are, there will still be slight tolerances between the 3D scan and the real part.

In the example below for instance, if you want a hole that is 50mm, manual measurement ensures that everything is correct to size, not a millimeter more or less. Reverse engineering with CAD software helps to eliminate these variations in data.

Our team’s expertise and long term experience pays off in this area.

More about Tolerances:

We check on the tolerances with you, to ensure they meet the requirements of your products and the quality of your pointcloud or 3D scan data.

Manually reverse engineering is a process, where scanning tolerances of the 3D scan file are reversed to depict the original part’s intention or geometric shape.

Pointclouds out of simulation or quality inspection software are highly detailed. The Tolerances between those pointcloud and ready CAD files are very tight, because those files are usually intended to optimize products to a perfect status.

Here, reverse Engineering works generally the same way like on 3D Scan. The CAD data can be worked out very tight. The final comparison between pointcloud and CAD allows for variance below +/-0,005 mm.

Teamwork is how we win at projects

TEAMWORK is the basis of every successful project. Our engineers work on your data as a team, to map out technical details and create an end product that is high quality, functional and usable.

One of the most important members of the team is the team member who reverse engineers within the software. He or she must have sufficient personal experience including:

- Knowledge of all software functions

- Know all the mouse functions and keyboard shortcuts

- Construction experience

- The best approach to use to produce the best results within the shortest time.

But that person cannot work without the support of the rest of the team. Which is why at Mako Technics, we emphasize teamwork above all else when handling projects.

Reverse engineering: From construction steps to final output

During the reverse engineering process, we generate your CAD file in the software you choose. During this process, we work regularly inside the program and save the construction history of all the steps we take. You can access that history as part of the ready data.

Parametric features are very beneficial when working with CAD files.

• Simulations – FEM, ANSYS or material flow in moulds (Cadmould / Moldflow)

• Optimizations – product tolerance optimization (GOM inspect Pro)

1. Make an impression on paper

2. Build detailed units of the model

3. Modify the units until they fit on the pointcloud

4. Add parametric features to the units

5. Remodel the units some more

6. Continue adding parametric features

7. Compare pointcloud and cad data regularly to ensure fit

8. Assemble the parts together

9. Double check to ensure tolerances between STL and CAD data are below requested figures.

If tolerances are not reached, the engineer will modify the structure into smaller elements and go back to step 5 of above list, until his reverse engineering arrives at the required tolerance.

The general steps followed when creating native CAD data from Pointclouds based on simulation data include:

1. Check original CAD and pointcloud after simulation

2. Identify geometrical parts and free form faces

3. Rebuild first geometrical units of the model

3. Modify the units until they fit on the pointcloud

4. Rebuild free form areas and implement them into the geometrical base

5. Continue remodeling the units further

6. Compare pointcloud and CAD data regularly to ensure allowable tolerances

8. Assemble all the parts together.

9. Ensure requested tolerance between simulation file and CAD data are below requested figures

If tolerances can‘t be reached on the first attempt, the engineer will modify the structure into smaller elements and progress from step 5 of the above list, until the target tolerance is reached.

When reading the surface of a large object, the error margin can be huge and, the scanner might pick damage or dirt that’s on the surface.

Hence point clouds. Pointclouds are coordinates in space that represent a scanned object. After scanning, the points are then put together to create CAD data.

Below is the process we follow when reverse engineering generated Pointclouds:

1. Checking original CAD and pointcloud after 3D scan

2. Generate average pointcloud file out of 5 test parts

3. Rebuild geometrical units of the model

3. Modify the units until they fit on the pointcloud

4. Remodel free form areas and fix them into the geometrical base

5. Continue with further units

6. Compare data base and cad model regularly to ensure tolerances are reached

8. Assemble all faces together.

9. Ensure tolerance between simulation file and CAD data are below the tolerance that the customer is asking for.

It is standard practice to cut the CAD structure when dealing with large file sizes. The different parts are then combined to form the original geometry.

Industrial usage of reverse engineering in various fields

Classic clay modeling is still widely used during the design process for creating shapes and models.

Reverse engineering here, helps in two ways:

• 3D Scan of clay model

• Reverse engineering and free form modelling of the 3D Scan – STL file (Catia V5/V6)

Example: Mold-milling of a new Santa Claus, to be made of chocolate

Cadmold software simulates material flow during injection moulding processes. Simulation is done on the original CAD construction file and the result of this simulation is a pointcloud with variations on the surface. This pointcloud represents the expected result of the moulding process.

• Moldflow simulation of hot plastics with Cadmold software

• Reverse engineering with free form modelling and remodeling of parametric geometries (various software)

Example: Injection molding of plastic parts for use in hospital ventilators

Our Services

We provide different services. Pick yours

OUR BLOG

Top Reverse Engineering Tools for Solidworks Users For Solidworks users looking to enhance their design capabilities, leveraging reverse engineering tools…

Unlocking Reverse Engineering with 3D Scanning Technology 3D scanning technology is revolutionizing the field of reverse engineering, offering unparalleled accuracy…

Top Techniques for 3D Reverse Engineering Success 3D reverse engineering is revolutionizing how industries approach design, prototyping, and product development.…

Top Benefits of 3D Inspection Scanners for Quality Control Quality control is an essential aspect of manufacturing and product development,…